Descriptions of functions

10.3 Communication according to PROFIdrive

SINAMICS DCM DC Converter

Operating Instructions, 12/2018, A5E34763375A

439

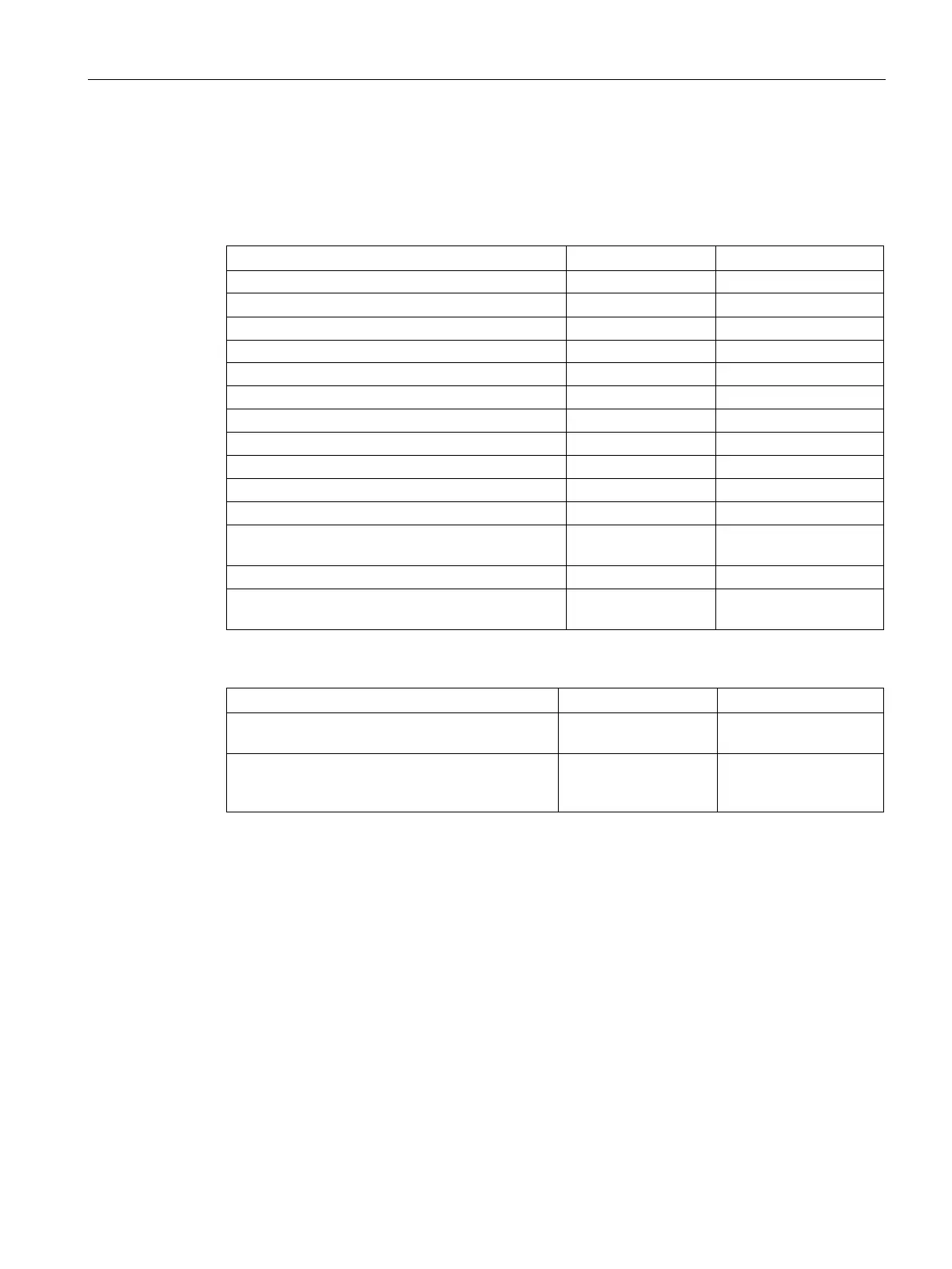

Properties of the cyclic interfaces IF1 and IF2

The following table shows the different features of the two cyclic interfaces:

Table 10- 26 Properties of the cyclic interfaces IF1 and IF2

Setpoint (BICO signal source)

Actual value (BICO signal sink) p2051, p2061 p8851, p8861

PROFIdrive telegram selection (p0922)

Isochronous mode possible (p8815[0])

PROFIsafe possible (p8815[1])

Direct data exchange (PROFIBUS only)

List of drive objects (p0978)

Max. PZD (16-bit) setpoint / actual value DC_CTRL

Max. PZD (16-bit) setpoint / actual value encoder

Max. PZD (16-bit) setpoint / actual value TM31

Max. PZD (16-bit) setpoint / actual value

5 / 5 5 / 5

Max. PZD (16-bit) setpoint / actual value TM150

Max. PZD (16-bit) setpoint / actual value CU

20 / 25 20 / 25

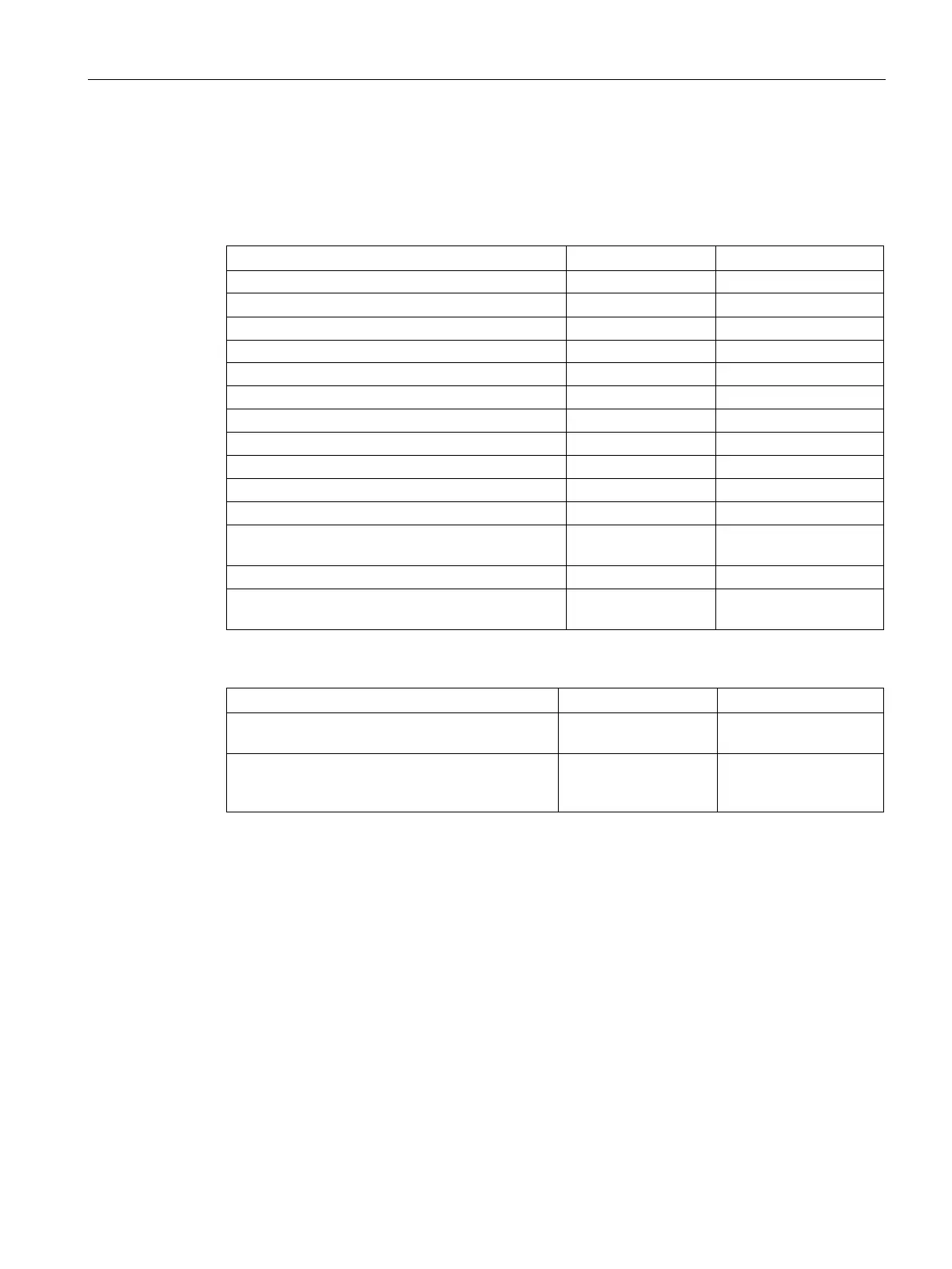

Table 10- 27 Implicit assignment of hardware to cyclic interfaces for p8839[0] = p8839[1] = 99

Plugged hardware interface

No option, only use Control Unit onboard interface

(PROFIBUS, PROFINET or USS)

Control Unit onboard --

CUD with CBE20 Communication Board Ethernet COMM BOARD Control Unit onboard

PROFIBUS or Control

Parameter p8839[0,1] is used to set the parallel operation of the hardware interfaces and the

assignment to the cyclic interfaces IF1 and IF2 for the Control Unit drive object.

The object sequence for process data exchange via IF2 depends on the object sequence

from IF1; see "List of drive objects" (p0978).

The factory setting of p8839[0.1] = 99 enables the implicit assignment (see previous table).

An alarm is generated in case of invalid or inconsistent parameterization of the assignment.

Loading...

Loading...