Cycles

9.5 Taper grinding - CYCLE405

Cylindrical grinding

Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

165

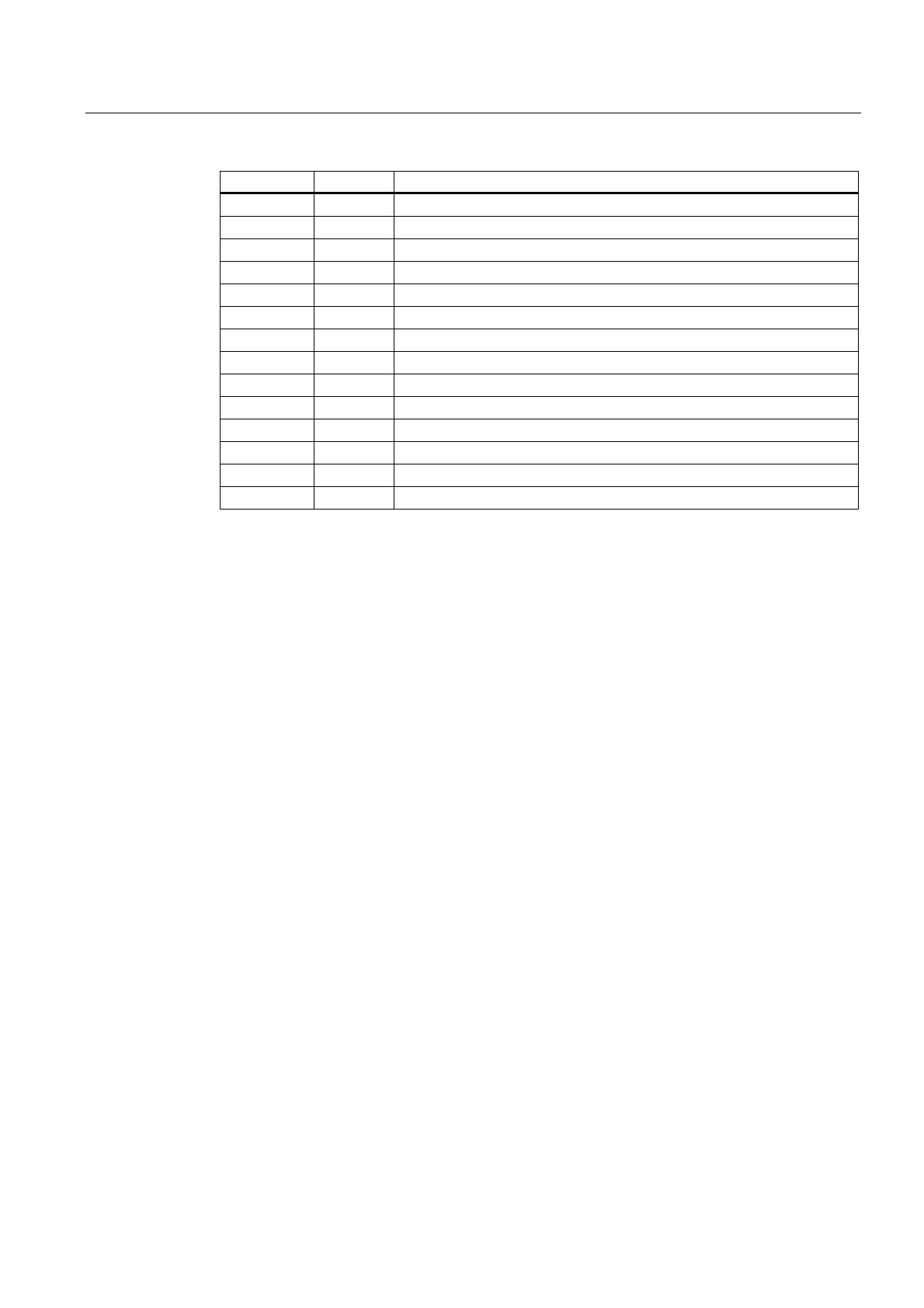

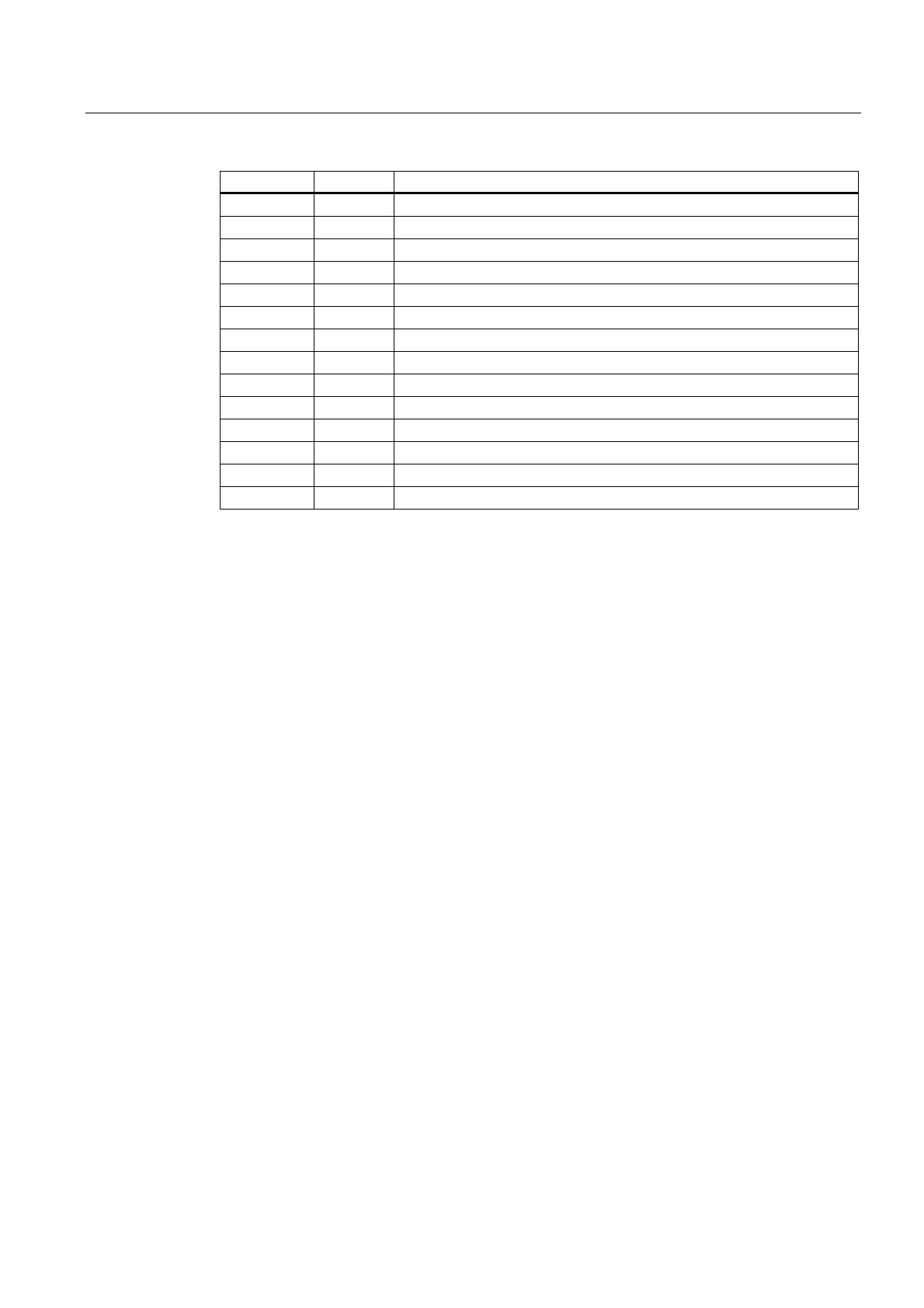

Parameter Data type Meaning

D_SL INT Dressing strokes after finishing

D_FS INT Dressing strokes after fine-finishing

ESL REAL Off-loading prior to finishing

EFS REAL Off-loading prior to fine-finishing

FX_SR REAL Infeed feedrate when roughing

FX_SL REAL Infeed feedrate when finishing

FX_FS REAL Infeed feedrate when fine-finishing

FZ_SR REAL Z feedrate when roughing

FZ_SL REAL Z feedrate when finishing

FZ_FS REAL Z feedrate when fine-finishing

MZ INT Measurement control Yes=1 / No=0

KS INT Acoustic emission Yes=1 / No=0

F_KS REAL Feedrate for air grinding [mm/min]

UWERK REAL Workpiece peripheral speed [m/min]

Function

The taper grinding cycle is called up to process a cone that is wider than the wheel. This

cone is ground using the oscillation method or multiple plunge-cutting.

Infeed when longitudinal grinding takes place at the reversal points. Intermediate dressing,

interruption and use of the handwheel are all supported (handwheel only for cylindrical

parts). The buttons react immediately. Following the technological steps of roughing and

finishing, dressing or off-loading can be programmed.

Sequence

Approach allowance position, approach X starting position and Z position. Start of the

oscillating motion after approaching with acoustic emission, infeed in the reversal points or

processing of the multiple plunge-cuts with or without acoustic emission.

The first infeed once oscillating motion has commenced is adjusted to ensure that all

additional infeed operations correspond to the infeed amount. This process is also performed

following interruptions, intermediate dressing and deselection of the handwheel override

function. Following interruption/dressing, an off-loading value is applied as the tool

approaches the machining start point. At the end, the tool retracts to the starting position.

Loading...

Loading...