Cycles

9.9 Multiple plunge-cutting – CYCLE411

Cylindrical grinding

178 Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

● _GC_KORR = 0: Nominal/actual deviation is taken into account for the wheel

● _GC_KORR = 1 - Nominal/actual deviation is taken into account for the active work offset

● _GC_KORR = 2 - Nothing is taken into account

Explanation of the parameters

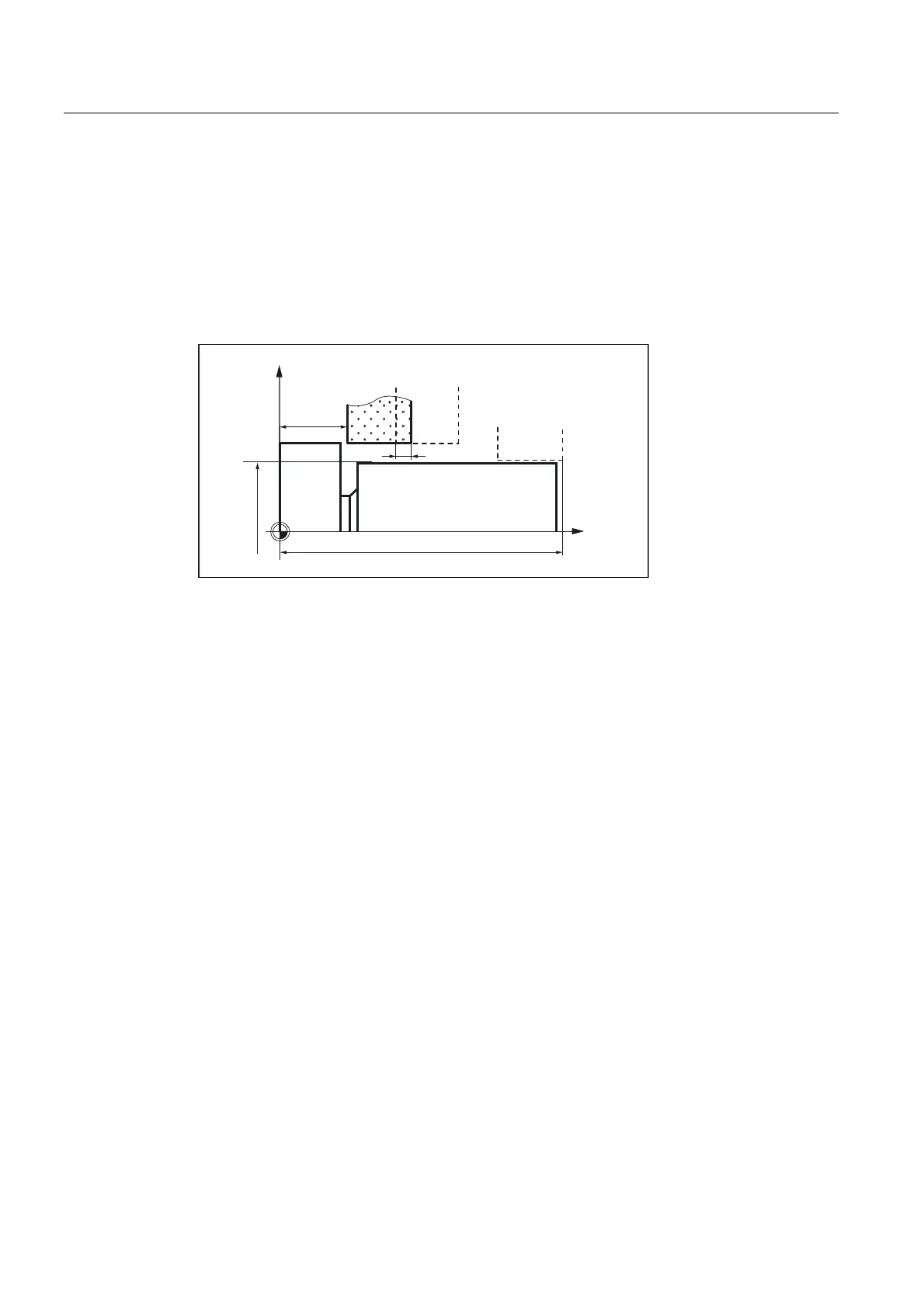

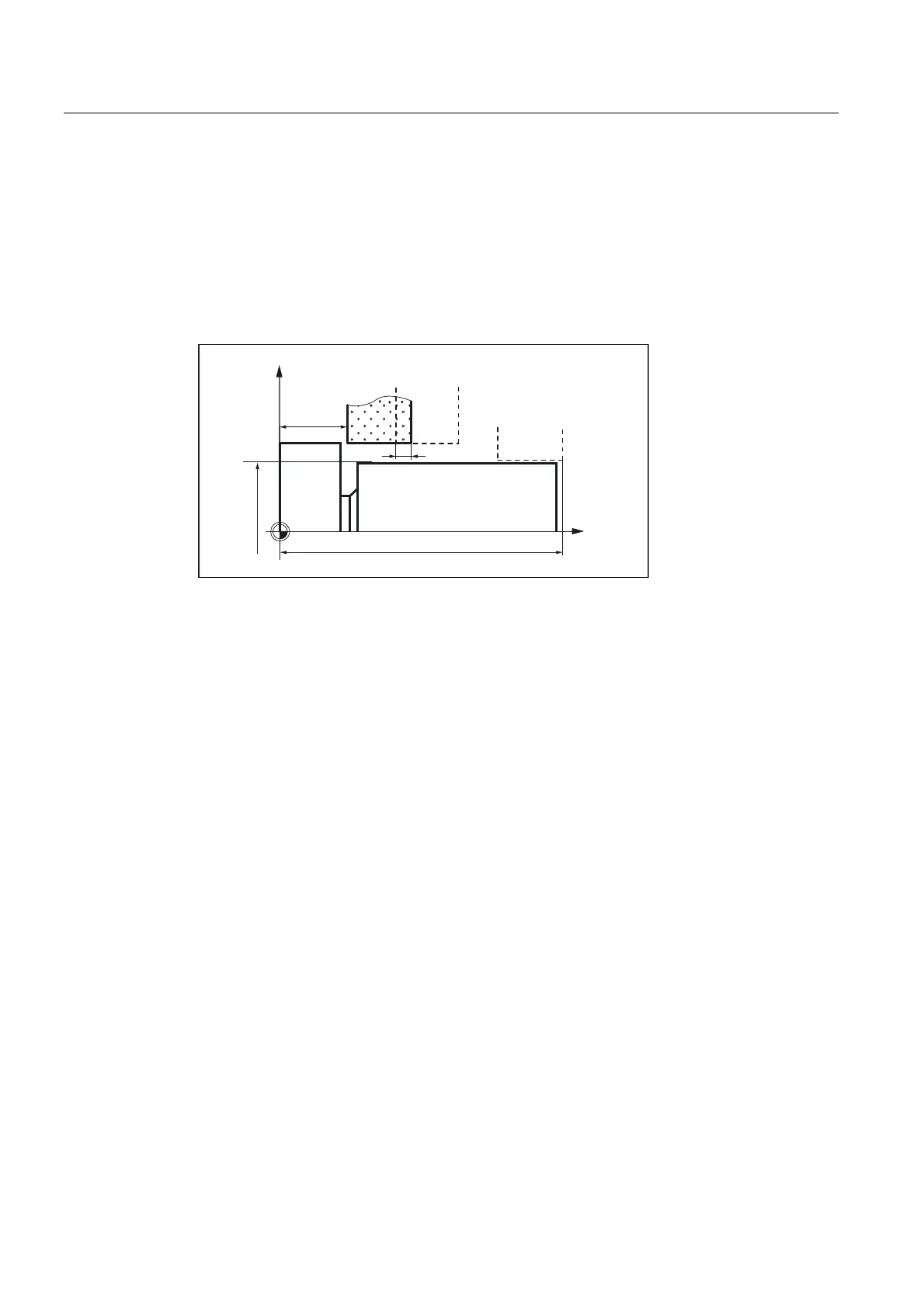

8%/

=B67

;

=

=B(1'

;B62//

N_SITZ (seat number)

The N_SITZ parameter is used to enter the number of the seat to be machined on the

workpiece.

X_SOLL (setpoint diameter)

The setpoint diameter corresponds to the finished dimension in the X direction.

Z_ST (starting position in Z), Z_END (target position in Z)

Z_ST and Z_END are used to define the starting and target positions of the grinding motion

in the Z direction.

UBL (overlap)

This parameter is used to specify the overlap of the wheel for multiple plunge-cutting.

B_ART (machining type)

The B_ART parameter is used to define the machining type used to machine a technological

section. Possible values for B_ART lie in the range between 1 and 3 with the following

meaning:

1 = roughing

2 = finishing and fine-finishing

3 = roughing, finishing and fine-finishing

A_LU (air allowance)

The term 'air allowance' is used to denote the distance between the starting position in X and

the stock allowance for roughing.

Loading...

Loading...