Programming

10.1 Fundamental Principles of NC Programming

Cylindrical grinding

232 Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

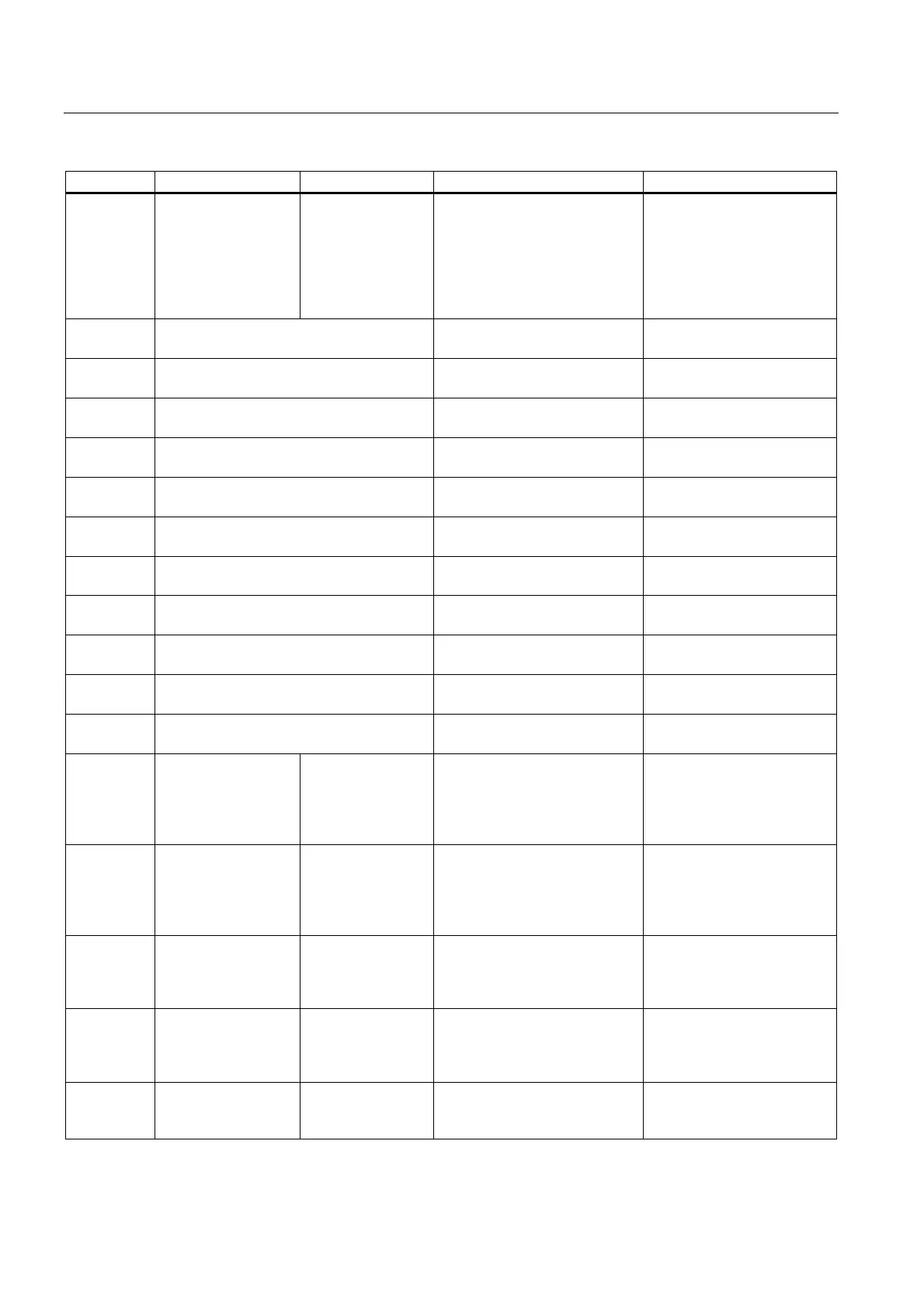

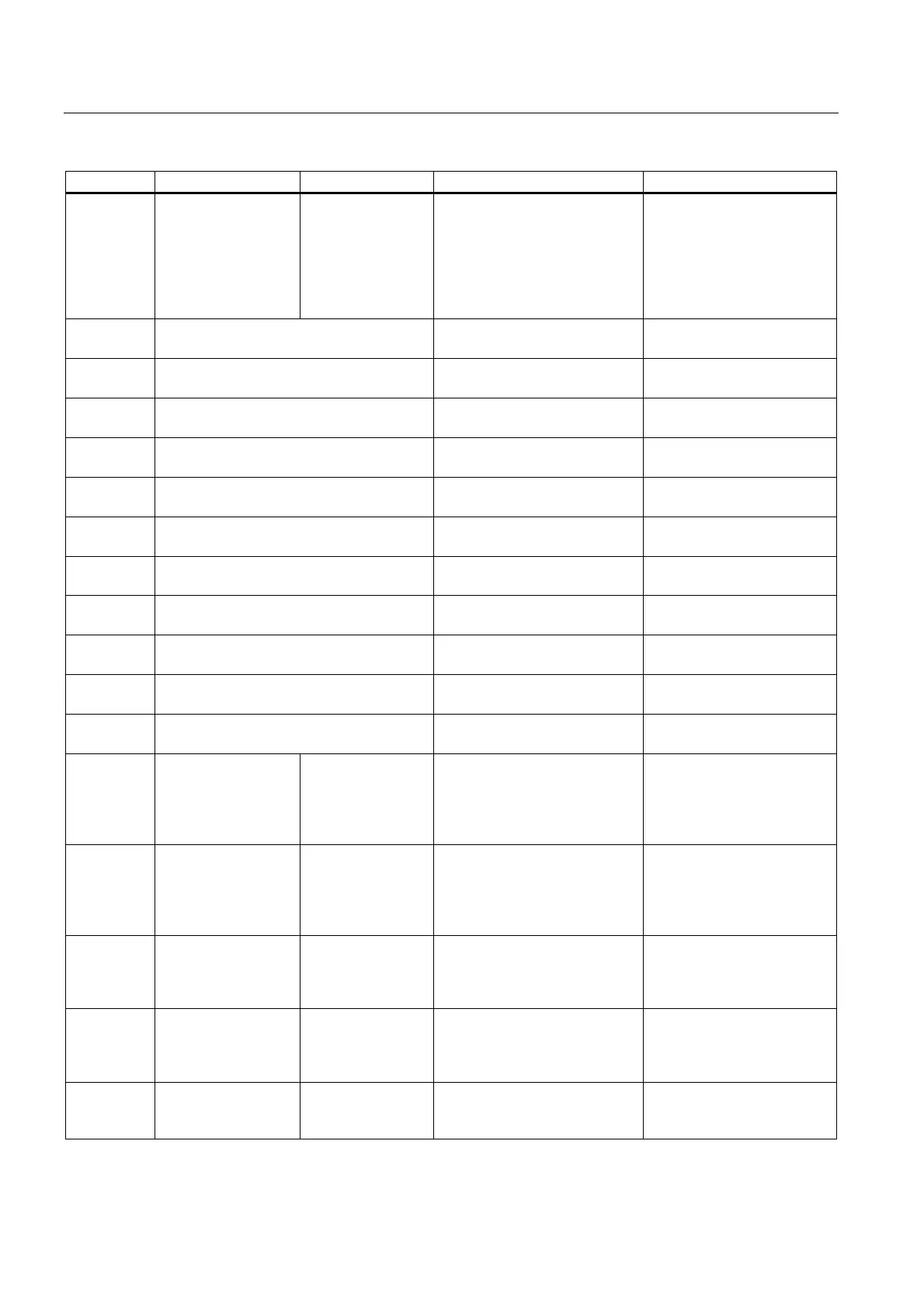

Address Meaning Value assignments Information Programming

CYCLE... Machining cycle Only specified

values

The call of the machining cycles

requires a separate block; the

appropriate transfer parameters

must be loaded with values.

Special cycle calls are also

possible with an additional

MCALL or CALL.

CYCLE406 Z positioning with grinding wheels N10 CYCLE406(...) ;

separate block

CYCLE407 Safety position N10 CYCLE407(...) ;

separate block

CYCLE410 Plunge-cutting N10 CYCLE410(...) ;

separate block

CYCLE411 Multiple plunge-cutting N10 CYCLE411(...) ;

separate block

CYCLE412 Shoulder plunge-cutting N10 CYCLE412(...) ;

separate block

CYCLE413 Oblique plunge-cutting N10 CYCLE4130(...)

;separate block

CYCLE414 Radius grinding N10 CYCLE414(...) ;

separate block

CYCLE415 Oscillation N10 CYCLE415(...) ;

separate block

CYCLE416 Dressing and profiling N10 CYCLE416(...) ;

separate block

CYCLE420 General workpiece data N10 CYCLE420(...) ;

separate block

CYCLE430 Dressing with profile roller N10 CYCLE430(...) ;

separate block

DC Absolute coordinate;

approach position

directly(for rotary

axis, spindle)

- It is also possible to specify the

dimensions for the end point of

a rotary axis with DC(...)

irrespective of G90/G91; also

applies to spindle positioning

N10 A=DC(45.3) ;Approach

absolute position of the A

axis directly

N20 SPOS=DC(33.1);

Position spindle

DEF Definition instruction Defining a local user variable of

the type

BOOL, CHAR, INT, REAL,

directly at the beginning of the

program

DEF INT VARI1=24, VARI2 ;

2 variables of the type INT

; name defined by user

FRC Non-modal feedrate

for chamfer/rounding

0, >0 In case FRC=0: Feedrate Fwill

act

For the unit, see F and G94,

G95;

for chamfer/rounding, see

CHF, CHR, RND

FRCM Modal feedrate for

chamfer/rounding

0, >0 In case FRCM=0: Feedrate

Fwill act

For the unit, see F and G94,

G95;

for rounding/modal rounding,

see RND, RNDM

FXS

[

axis

]

Travel to fixed stop =1: select

=0: Deselection

Axis:

Use the machine identifier N20 G1 X10 Z25 FXS[Z1]=1

FXST[Z1]=12.3 FXSW[Z1]=2

F...

Loading...

Loading...