1

08/2005 Introduction

1.2 Workstation

1

♥ Siemens AG, 2005. All rights reserved

SINUMERIK 840D sl Operation/Programming ShopTurn (BAT) – 08/2005 Edition 1-19

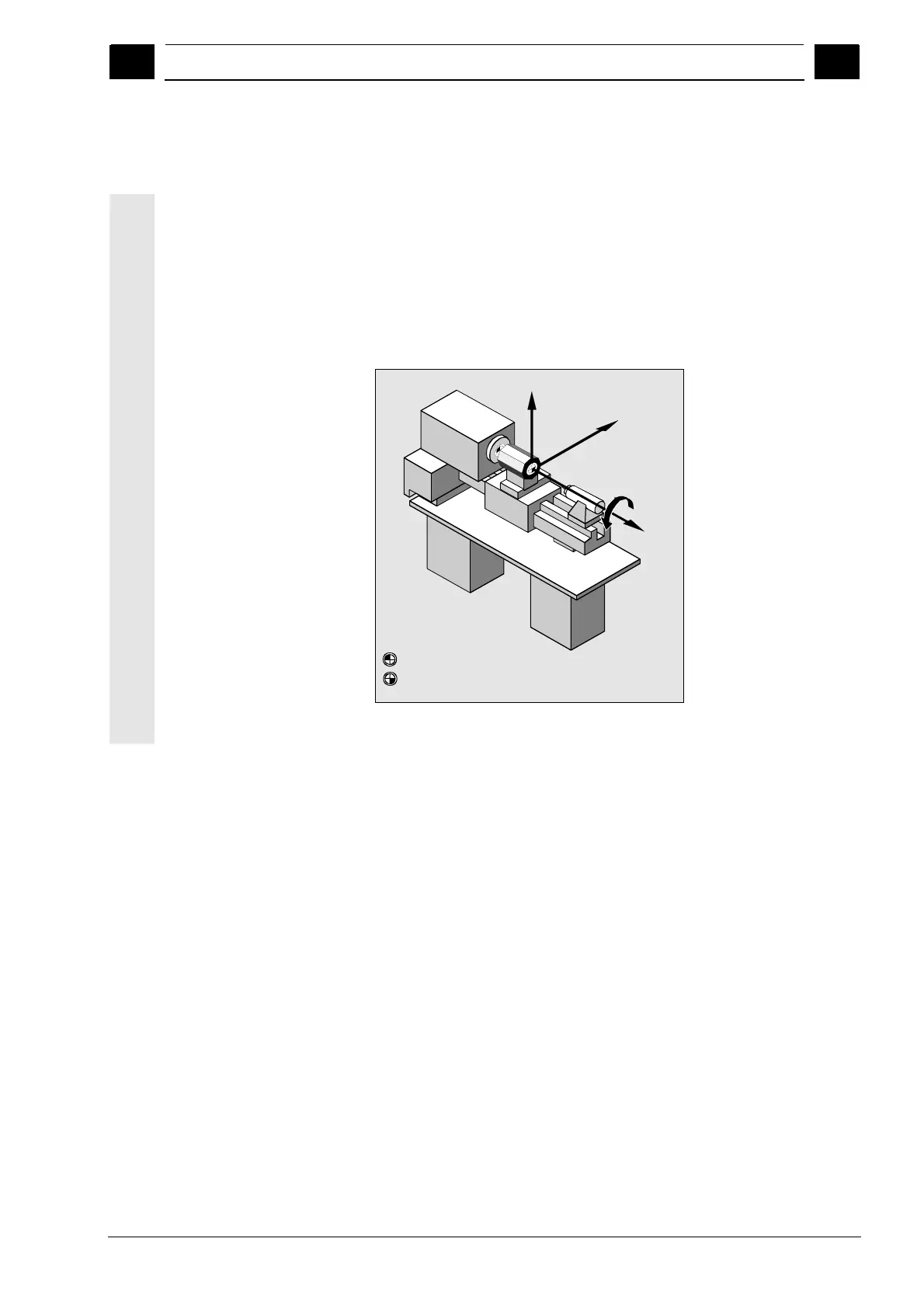

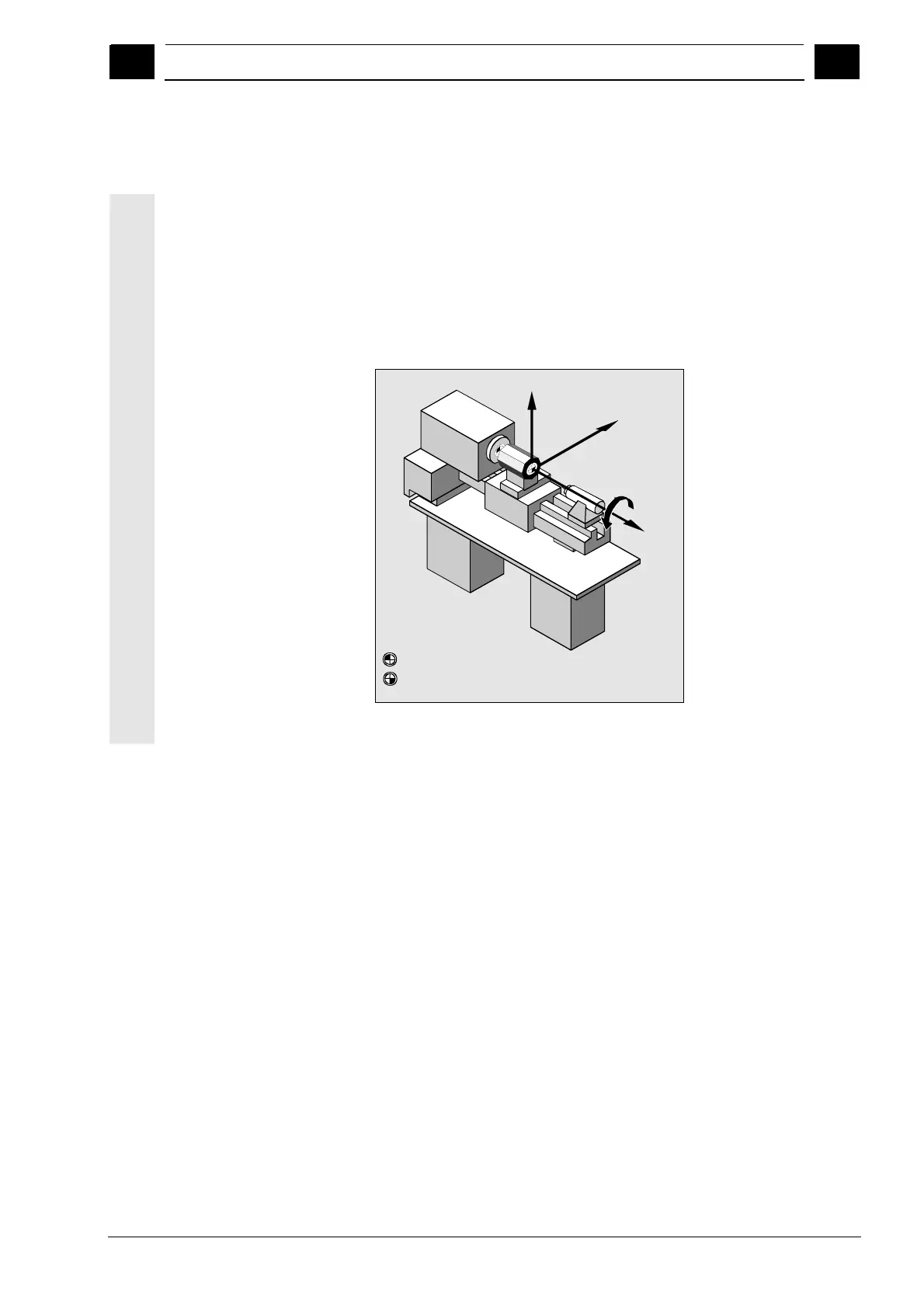

1.2.1 Coordinate system

When machining a workpiece on a lathe, one basically uses a right-

angled coordinate system. This consists of the three coordinate axes

X, Y, and Z which are parallel to the machine axes. The coordinate

axis Y does not have to be set up. Spindle axis Z is an independently

rotating axis and is designated with the letter C.

The positions of the coordinate system and the machine zero depend

on the type of machine used.

W

M

X+

Z+

Y+

W = Workpiece zero

C

M = Machine zero

Position of the coordinate system, machine zero

and workpiece zero (example)

Loading...

Loading...