5

08/2005 ShopTurn Functions

5.4 Contour turnin

5

♥ Siemens AG, 2005. All rights reserved

SINUMERIK 840D sl Operation/Programming ShopTurn (BAT) – 08/2005 Edition 5-223

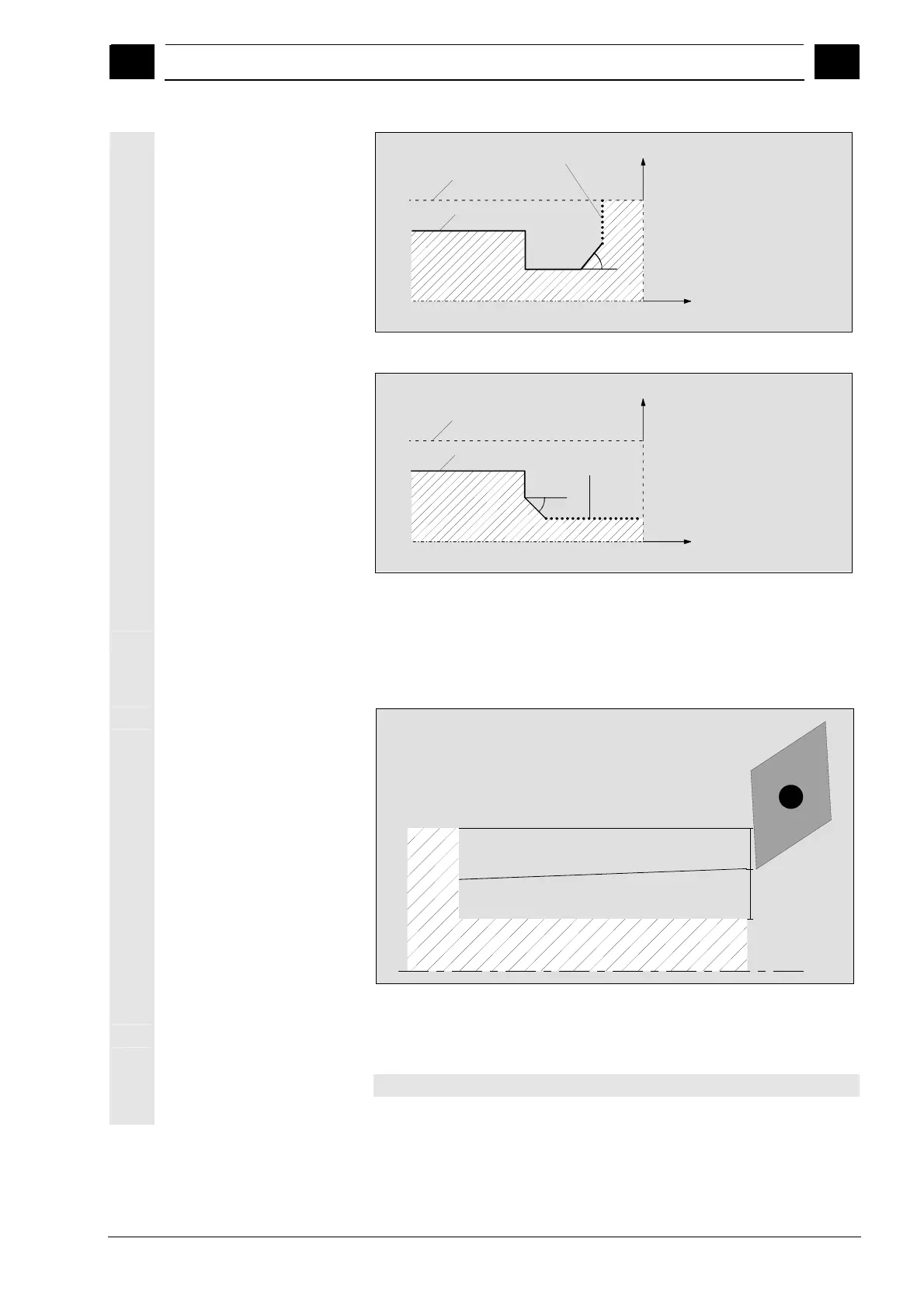

Contour finish

Unmachined part

Finished part

α

α >

1: Finish to top

X

Z

α =45°

Boundary between unmachined and finished parts at the top

Contour finish

Unmachined part

Finished part

α

α = 1

: Finish to side

X

Z

α = − 45°

Boundary between unmachined and finished parts at the side

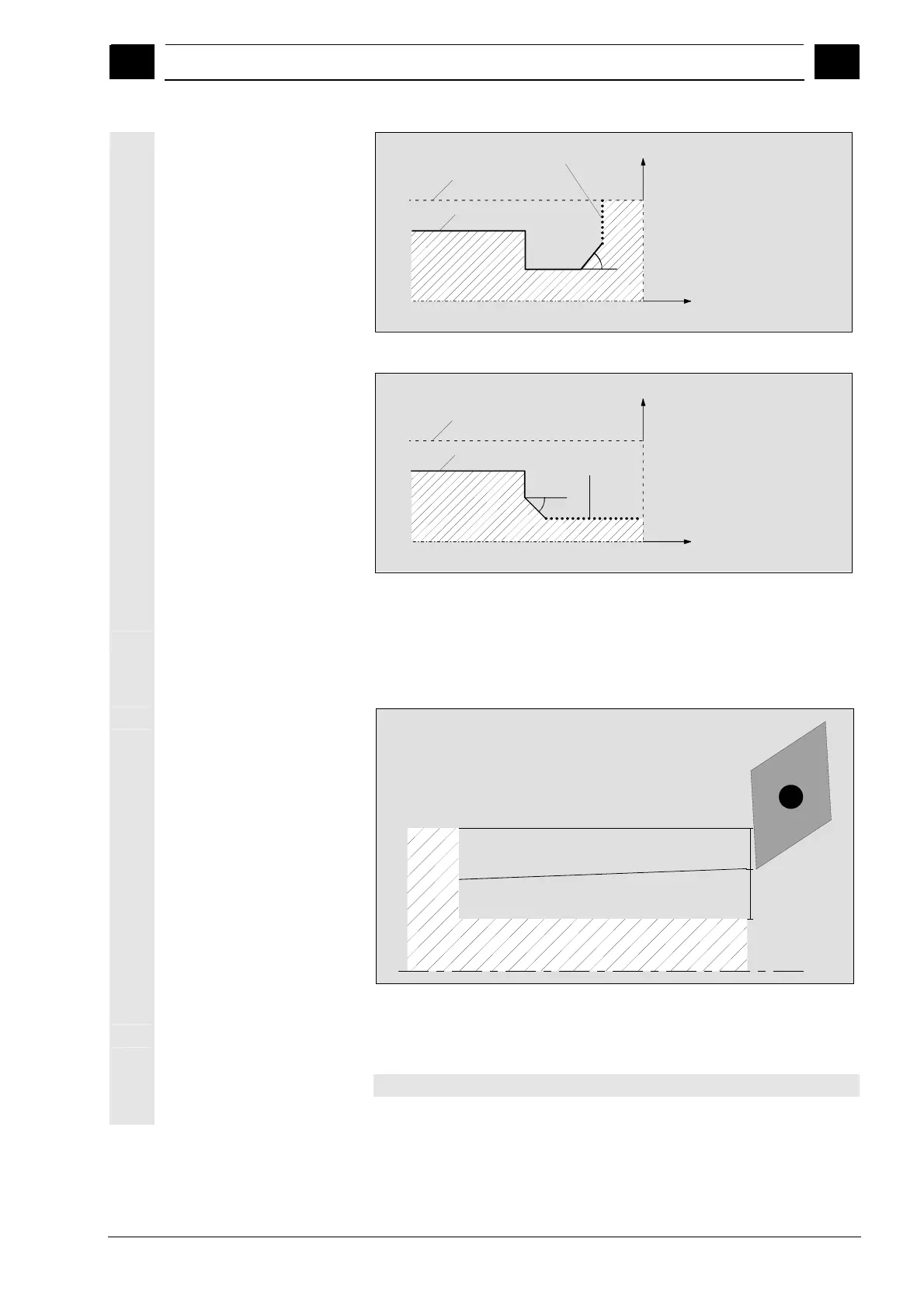

Alternating cutting depth

Instead of working with constant cutting depth D, you can use an

alternating cutting depth to vary the load on the tool edge and

increase the tool life.

First cut

Second cut

D

D

D - 10%

D - 10%

Alternating cutting depth

The percentage for alternating cutting depth is stored in a machine

data code.

Please also refer to the machine manufacturer's instructions.

Loading...

Loading...