Configuration

6.2 Configuring the busbar run layout

SIVACON 8PS - Configuring with LX system

114 Configuration Manual, 10/2011, A5E02194899-02

6.2.2.3 Planning in the case of vertical busbar runs

General procedure

The following applies when considering the layout of the busbar run:

● Recording of the determining busbar elements of the run: Feeder units, junction units and

end cap

● Calculation of the run lengths between feeder units, junction units and end cap

● Providinig feeder units with fixed points

● Dividing run lengths into sub-lengths using fixed points.

● Configuring expansion compensation

● Configuring fixing bracket per storey.

Maximum permissible sub-lengths L1

After recording the infeeds, junction units and end cap within a run, the following run layouts

can result:

● Busbar run layout between two junction units (Case 1)

● Busbar run layout between junction unit and end cap (Case 2)

● Busbar run layout between infeed and junction unit (Case 3)

● Busbar run layout between infeed and end cap (Case 4).

Subdivision into the maximum permissible number of sub-lengths L1 then takes place.

Sub-length L1 depends on the conductor material of the busbar trunking system as well as

the purpose of use (power transmission or distribution):

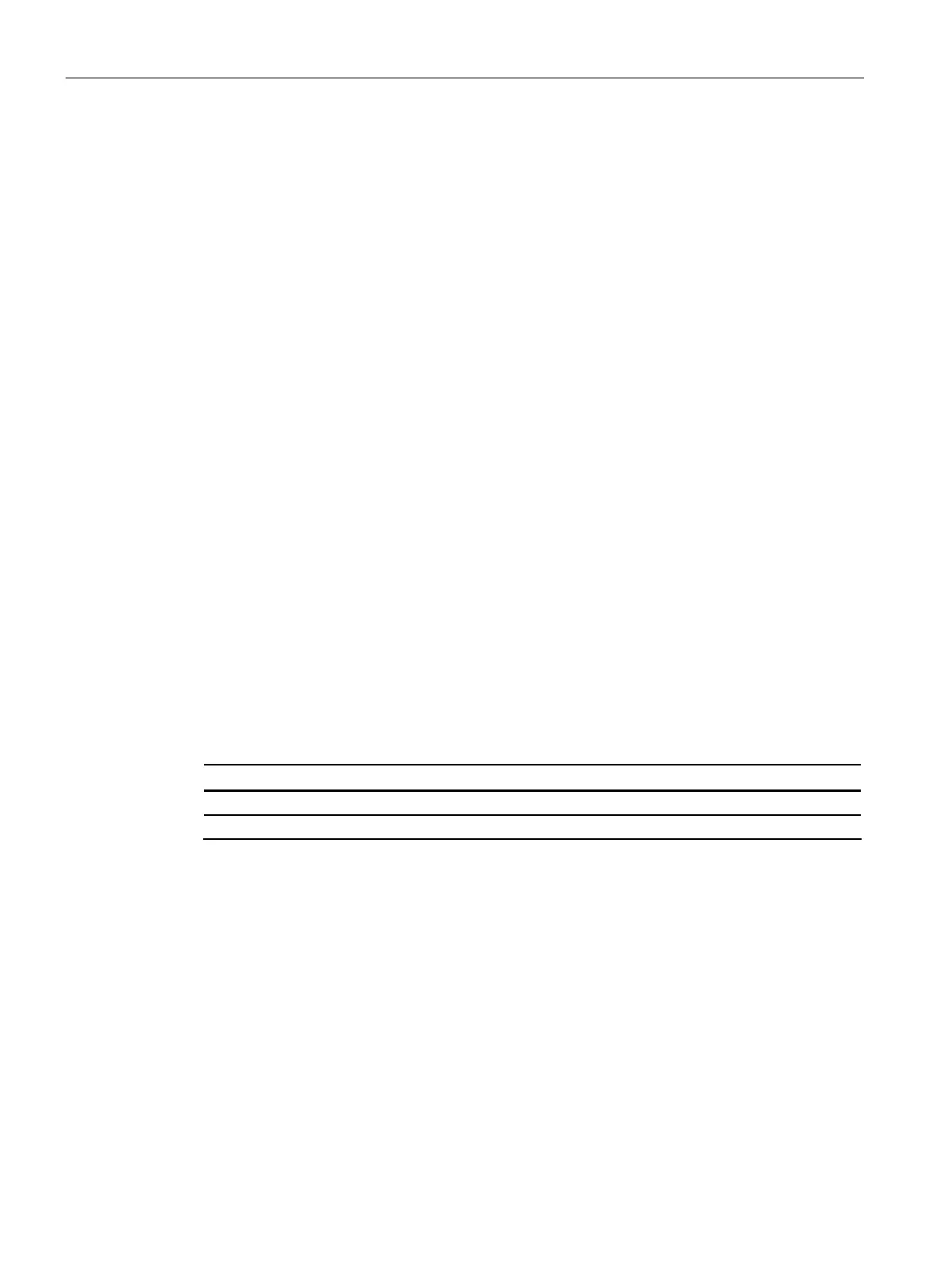

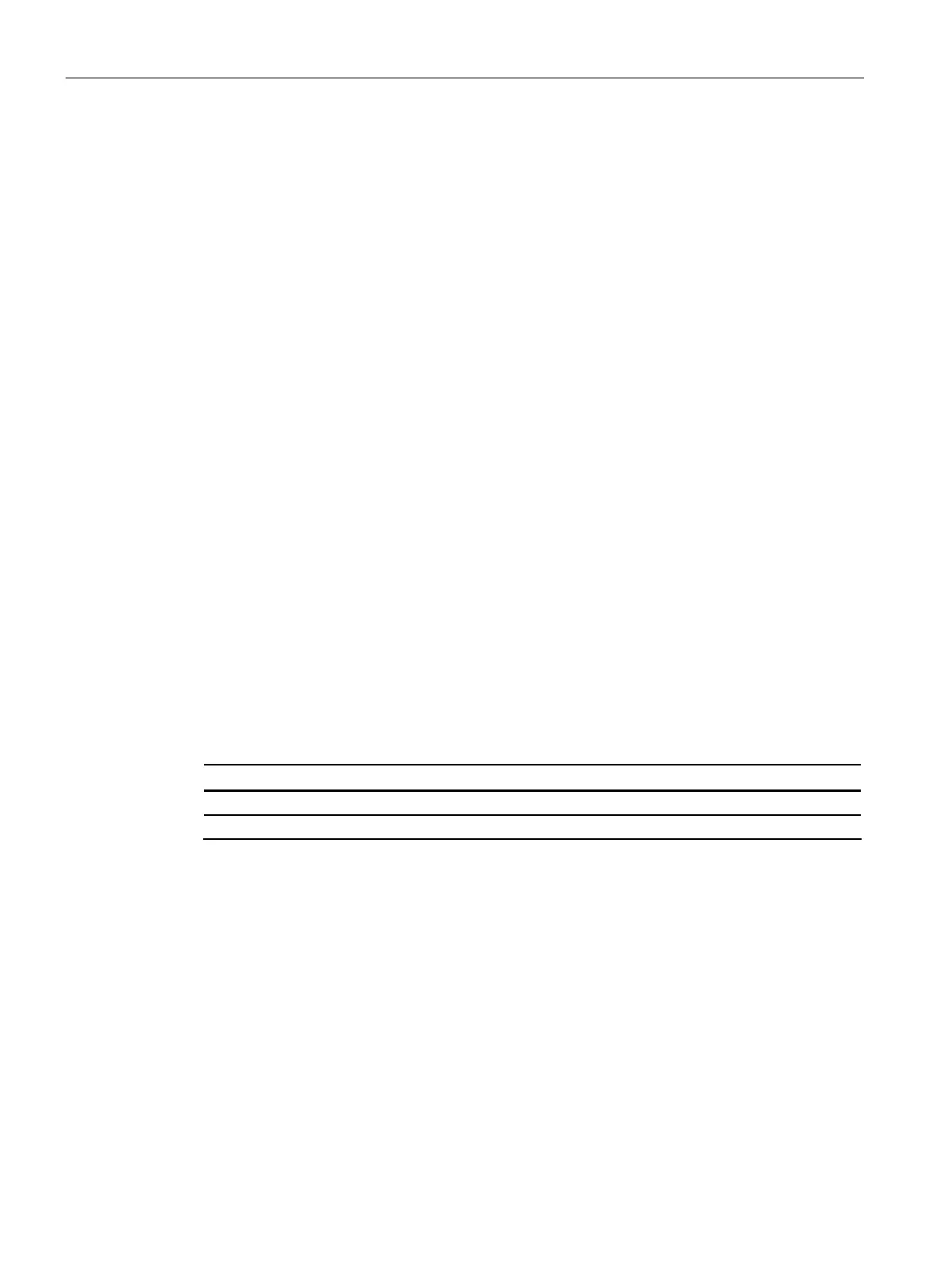

Conductor material Power transmission Power distribution

1)

Cu (LXC....) L1 ≤ 40 m L1 ≤ 60 m

Al (LXA....) L1 ≤ 25 m L1 ≤ 50 m

1)

At least one tap-off unit per storey

These sub-lengths are

● between two fixed points with expansion compensation

● between fixed point and end cap without expansion compensation.

For sub-lengths between infeed and fixed point with expansion compensation, sub-length L1

is halved.

Loading...

Loading...