Page 12 December 2007

Telescopic Boom Series

Models SJ61T & SJ66T

194312

Section 1 - Scheduled MaintenanceScheduled Maintenance Inspections

1.1 Scheduled Maintenance

Inspections

Begin the scheduled maintenance inspections by

checking each item in sequence for the conditions listed

in this section.

WARNING

To avoid injury, do not operate an aerial

platform until all malfunctions have been

corrected.

WARNING

To avoid possible injury, ensure aerial

platform power is off during visual and

daily maintenance inspections.

Electrical

Maintaining electrical components is essential to good

performance and service life of aerial platform.

Perform a visual inspection around the following areas:

• boom to platform cable harness

• engine compartment electrical panel

• engine wiring harness

• rotary manifold wiring

Hydraulic

Maintaining hydraulic components is essential to good

performance and service life of the aerial platform.

Perform a visual inspection around the following areas:

• hydraulic tank lter, ttings, hoses, emergency

power unit and turret/base surface

• engine compartment fittings, hoses, main

pump, lter and turret/base surface

• all hydraulic cylinders

• all hydraulic manifolds

• the underside of the turret

• the underside of the base

• ground area under the aerial platform

1.1-1 Manuals & Required Documents (B)

Ensure a copy of operating manual and other important

documents are enclosed in the manual storage box.

- Check to be sure manual storage box is

present and in good condition.

- Ensure manuals are legible and in good

condition.

- Always return manuals to the manual storage

box after use.

1.1-2 Labels (B)

Refer to the labels section in the operating manual and

ensure that all labels are in place and are legible.

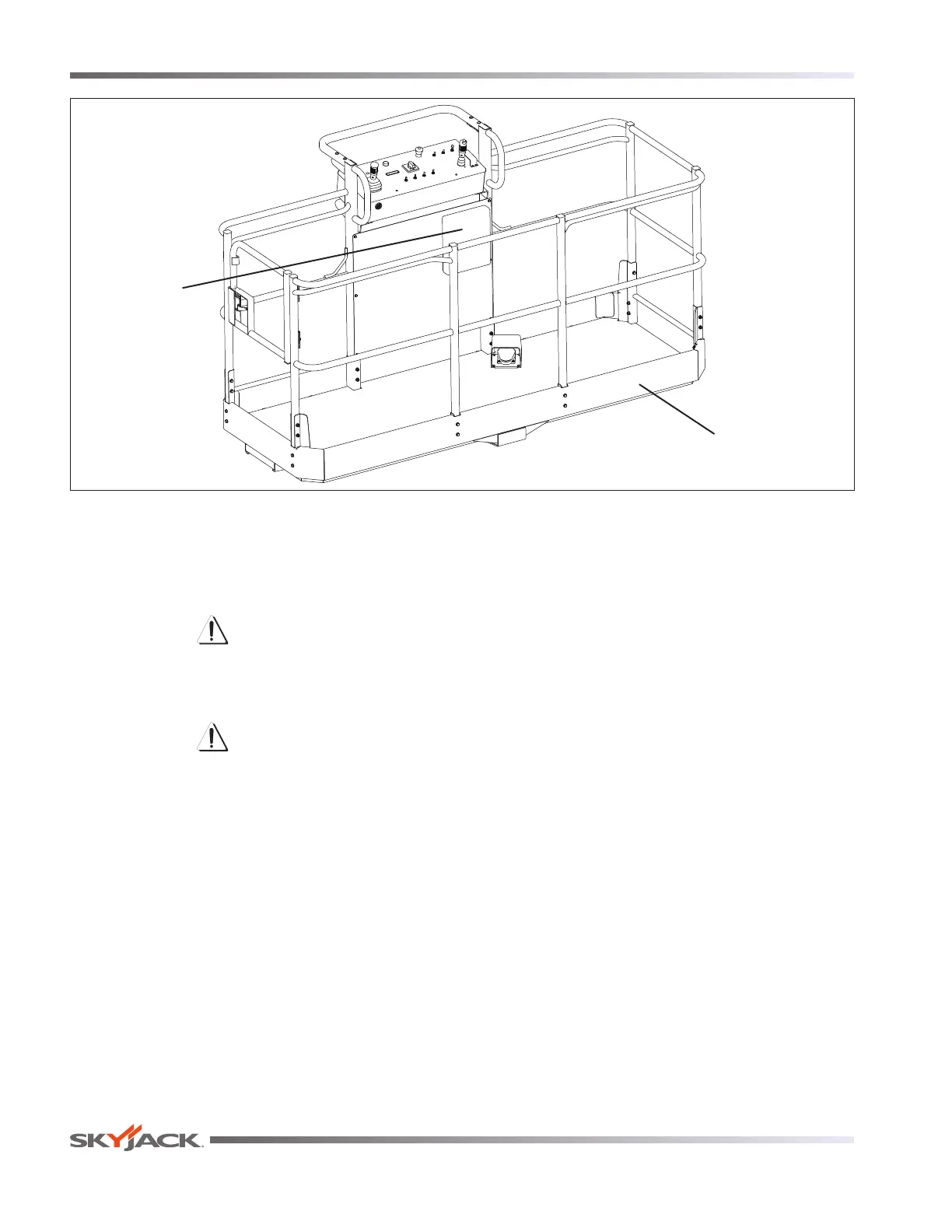

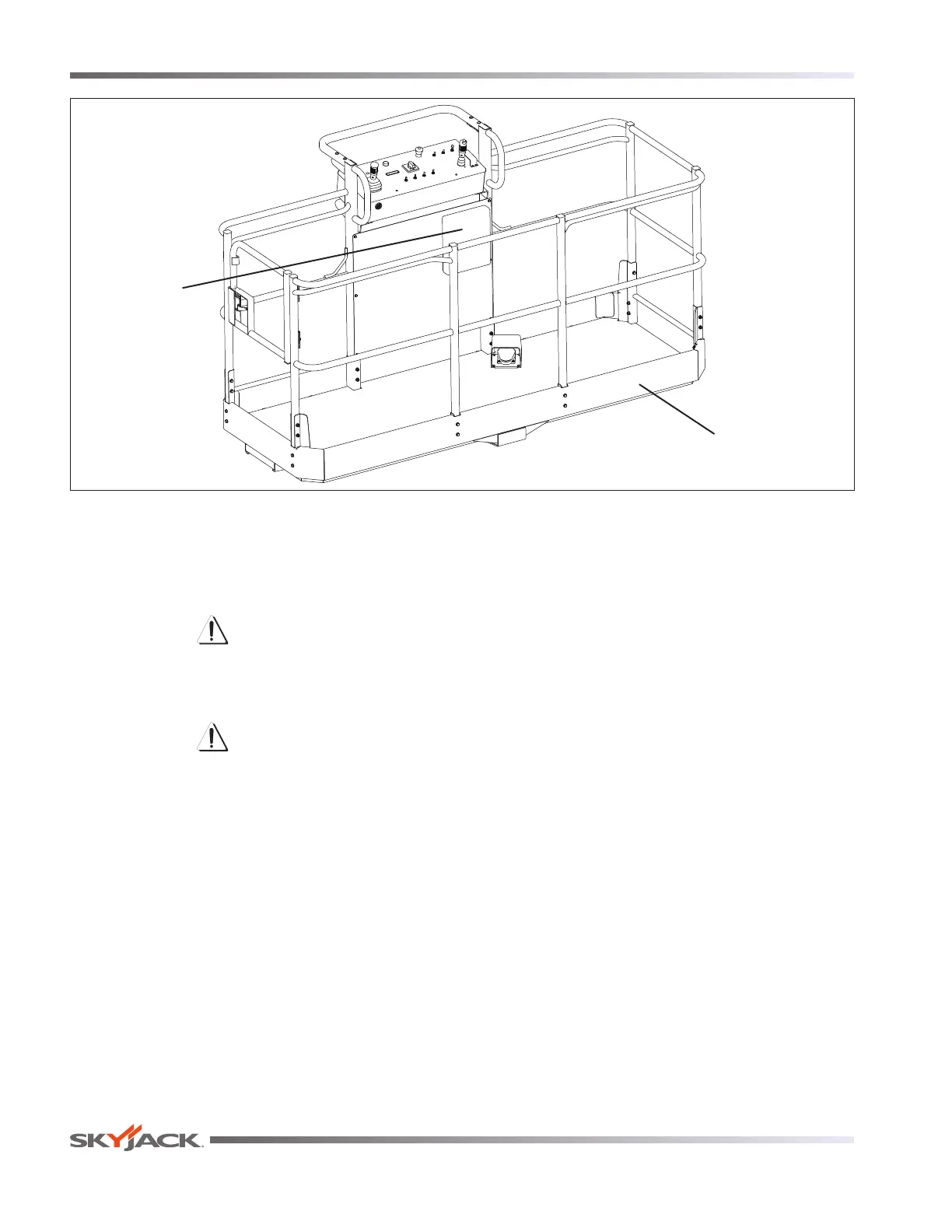

Platform

Assembly

Manuals

Scheduled Maintenance Inspections and Function Tests

Loading...

Loading...