Page 14 December 2007

Telescopic Boom Series

Models SJ61T & SJ66T

194312

Section 1 - Scheduled MaintenanceScheduled Maintenance Inspections

WARNING

Use original or manufacturer-ap-

proved parts and components for the

aerial platform.

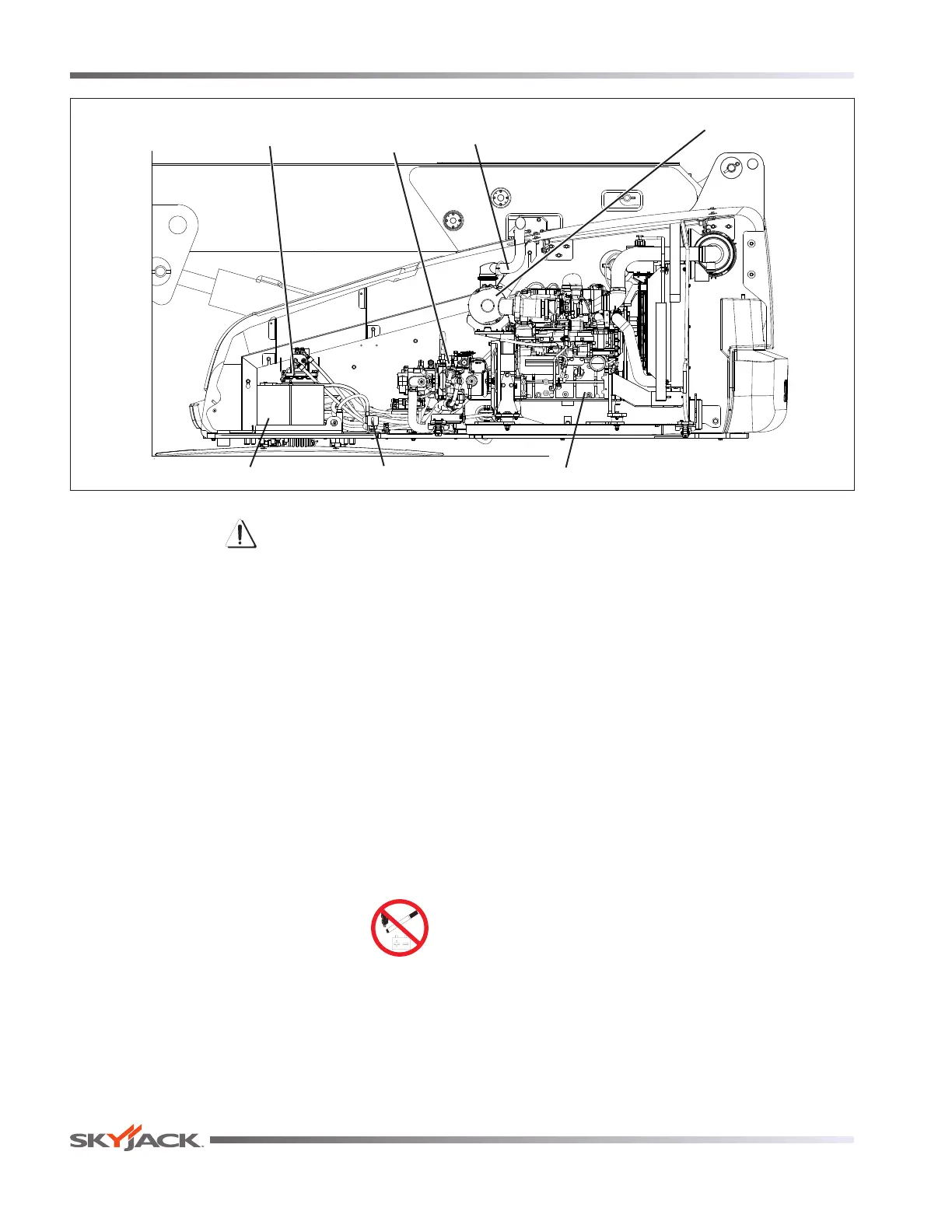

• Swing Drive Motor (B,C)

- Ensure there are no loose or missing

parts and there is no visible damage.

- Ensure all bolts are properly tightened.

- Ensure all ttings and hoses are properly

tightened and there is no evidence of

hydraulic leakage.

C - Annual Inspection

- For brake/motor oil replacement

procedure, refer to 5.3-3 Check Swing

Drive Motor Gearbox Oil.

• Turret Rotation Gear (B,C)

- Ensure there are no loose

or missing parts and there i s

no visible damage.

C - Annual Inspection

- For lube procedure, refer to 1.1

Scheduled Maintenance Inspections.

• High Pressure Filter (B,C)

(see Control Compartment for 61T/66T)

- Ensure housing is secure and shows no

visible damage or leakage.

C - Annual Inspection

- For lter element replacement procedure,

refer to For hydraulic oil replacement

procedure, refer to 5.7-2 C h a n g e

Hydraulic Oil..

• Hydraulic Pumps (B)

- Ensure there are no loose or missing

parts and there is no visible damage.

- Ensure all bolts are properly tightened.

- Ensure all ttings and hoses are properly

tightened and there is no evidence of

hydraulic leakage.

• Muffler and Exhaust (B)

- Ensure mufer and exhaust system are

properly secured, with no evidence of

damage.

• Engine Pivot Tray (B)

- Ensure there are no loose or missing

parts and no visible damage to the engine

pivot tray. Ensure that each tray-securing

bolt is in place.

Main Power Disconnect Switch

Battery

Mufer

Engine

Air Filter

Swing Drive Motor

Hydraulic

Pumps

Loading...

Loading...