Section 5

5.1

MAINTENANCE

General

NOTE

Equipments installed in hazardous atmospheres must be inspected in compliance with the IEC60079-

17 standard.

Below, there are some important maintenance procedures that should be followed in order to have safer

plant and easy maintenance.

In general, it is recommended that end users do not try to repair printed circuit boards. Spare circuit

boards may be ordered from SMAR whenever necessary.

The sensor has been designed to operate for many years without malfunctions. Should the process

application require periodic cleaning of the transmitter, the flanges may be easily removed and

reinstalled.

Should the sensor eventually require maintenance, it may not be changed on the field. In this case, the

possibly damaged sensor should be returned to SMAR for evaluation and, if necessary, repair. Refer to

the "Returning Materials" item at the end of this Section.

Diagnostic using Configuration Tool

Should any problem be noticed regarding the transmitter output, the configurator can be used to verify

what is the problem (see Table 5.1).

The configurator should be connected to the transmitter according to the wiring diagram shown on

Section 1, Figures 1.7, 1.8 and 1.9.

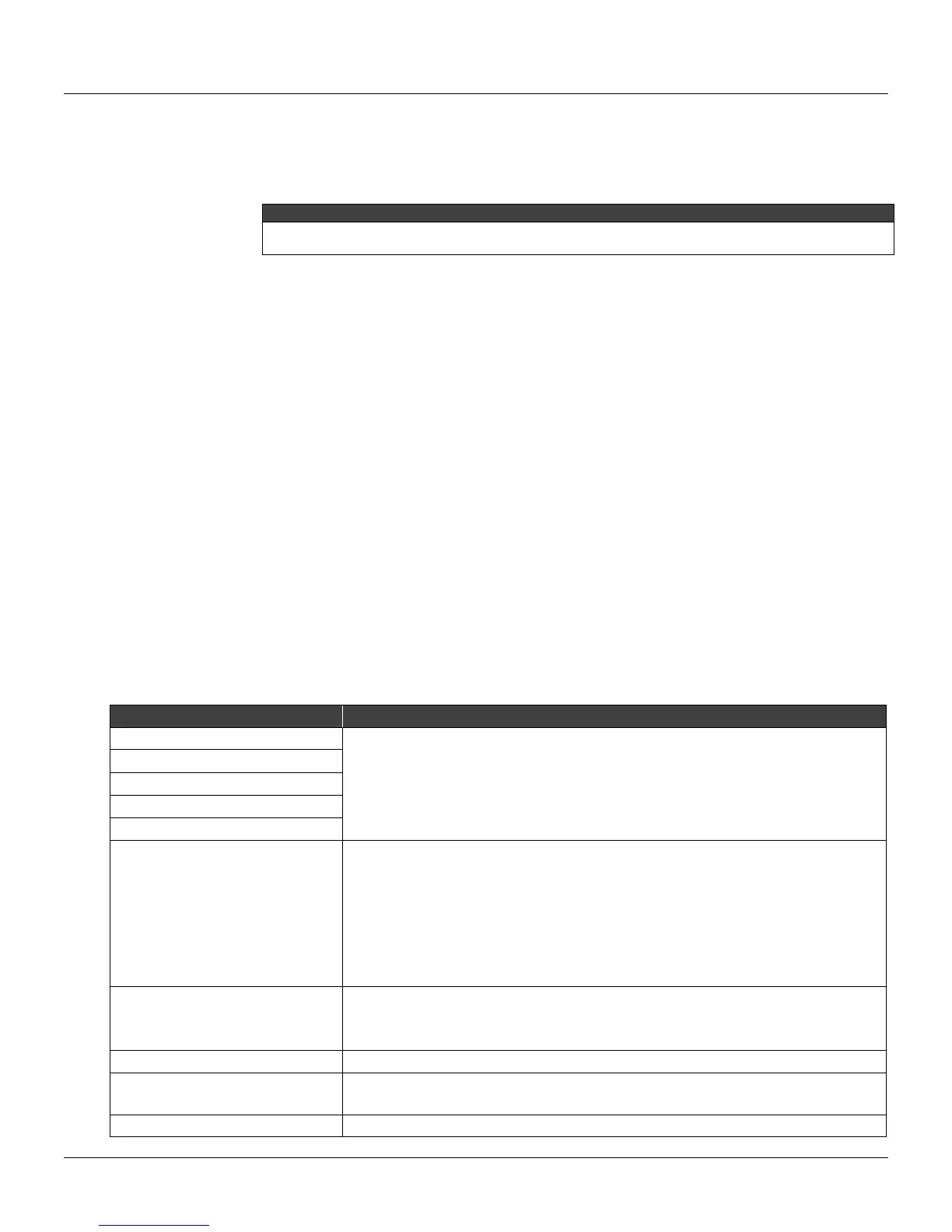

Error Messages

When communicating using the CONFIGURATOR the user will be informed about any problem found by

the transmitter self-diagnostics.

Table 5.1 presents a list of error messages with details for corrective actions that may be necessary.

ERROR MESSAGES POTENTIAL SOURCE OF PROBLEM

UART RECEIVER FAILURE:

The line resistance is not according to load limitation.

Excessive noise or ripple in the line.

Low level signal.

Interface damaged.

Power supply with inadequate voltage.

PARITY ERROR

OVERRUN ERROR

ERROR CHECK SUM

FRAMING ERROR

CONFIGURATOR RECEIVES NO

ANSWER FROM TRANSMITTER

Transmitter line resistance is not according to load limitation.

Transmitter not powered.

Interface not connected or damaged.

Repeated bus address.

Transmitter polarity is reversed.

Interface damaged.

Power supply with inadequate voltage.

CMD NOT IMPLEMENTED

Software version not compatible between configurator and transmitter.

Configurator is trying to carry out a LD301 specific command in a transmitter from

another manufacturer.

TRANSMITTER BUSY

Transmitter carrying out an important task, e.g., local adjustment.

XMTR MALFUNCTION

Sensor disconnected.

Sensor failure.

COLD START

Start-up or Reset due to power supplies failure.

Loading...

Loading...