LD301 - Operation and Maintenance Instruction Manual

5.14

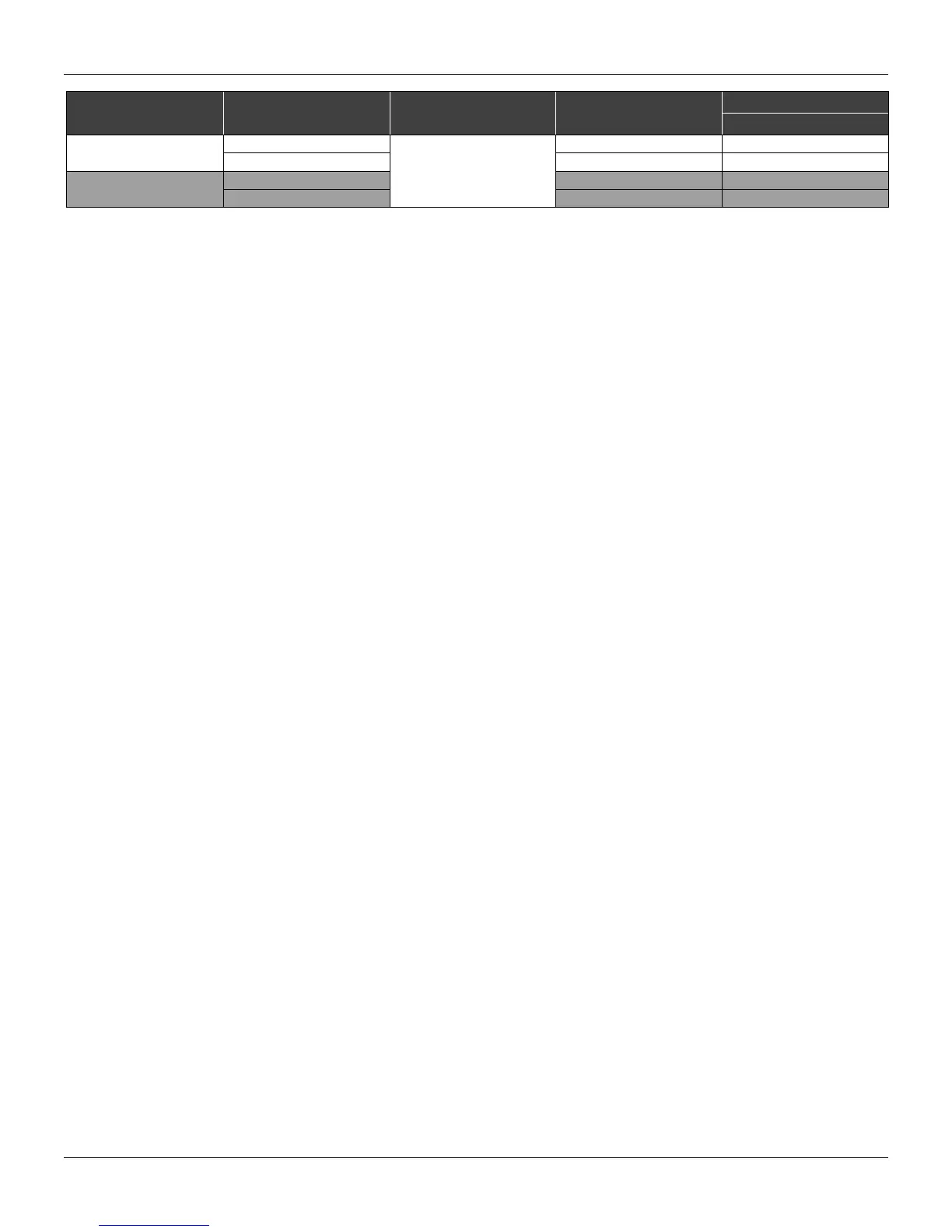

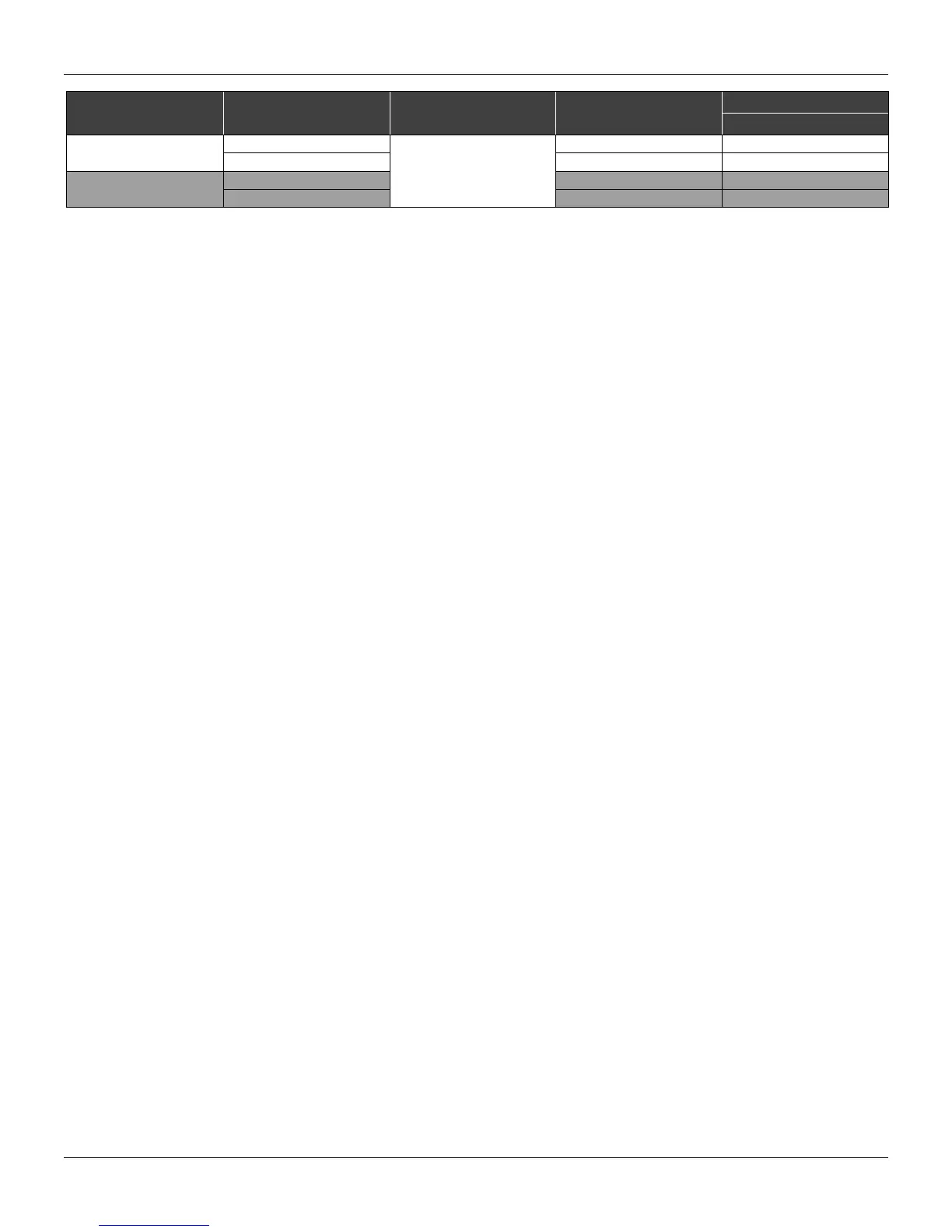

øN

CLASS NORM Ring

METALLIC RING

316L SST

3”

1500

ANSI B 16.20 RTJ

R35 400-0899

2500 R32 400-0898

4”

1500 R39 400-0903

2500 R38 400-0902

Table 5.5 - LD300L – Special models for Gasket in Steel – Without Extension

Application with Halar

Technical Specification

Halar

®

is chemically one of the most resistant fluoropolymer. It is a thermoplastic of the melting process

manufactured by Solvay Solexis, Inc. For its chemical structure, a 1:1 alternating ethylene copolymer

and chlorinetrifluoroethylene, Halar

® (ECTFE) offers an only combination of useful properties.

The diaphragms in 316L Stainless Steel covered with Halar

®

, are ideal for applications in contact with

aggressive liquids. They offer excellent resistance to the chemic and abrasion with a wide temperature

range. Halar

®

does not contaminate liquids of high purity and it is not affected by most of corrosive

chemists, usually found in the industries, including strong minerals, oxidant acids, alkalis, liquid oxygen

and some organic solvents.

Halar

®

is trademark of Solvay Solexis, Inc.

Performance Specification

For the performance specification see the equation below:

[1% SPAN x (URL/SPAN)] - Included temperature error*

Diameters/Capillary Length:

- 2” ANSI B 16.5, DN 50 DIN, JIS 50 A, for seals up to 3 meters of capillary and level models (by

inquiry).

- 3” ANSI B 16.5, DN 80 DIN, JIS 80 A, for seals up to 5 meters of capillary and level models.

- 4” ANSI B 16.5, DN 100 DIN, JIS 100 A, for seals up to 8 meters of capillary and level models.

*Temperature Limits:

+10 to 100°C;

+101 to 150°C (by inquiry).

TPE – Total Probable Error (Software)

Software to calculate the assembly error of the Pressure Transmitters with the possible connections to

the process.

TPE was developed to a fast and effective aid of the products related the pressure measurement. The

users are the Applications Engineer and Commercial Areas. The customer can request a report of

performance estimate to Smar.

This product allows doing simulations of possible assemblies, verifying important data as the error

estimates of the response time, of capillary length analysis and mechanical resistance of diaphragms

with temperature variation. See an example in the Figure 5.8.

Loading...

Loading...