LD301 – Operation and Maintenance Instruction Manual

6.12

LD301

SANITARY PRESSURE TRANSMITTER (CONTINUATION)

CODE

Flange Bolts and Nuts Material

A0

A1

Plated Carbon Steel (Default) (17)

316 SST

A2

A5

Carbon Steel (ASTM A193 B7M) (1) (17)

Hastelloy C276

CODE

Flange Thread for fixing accessories (adapters, manifolds, mounting brackets, etc)

D0

D1

7/16” UNF (Default)

M10 X 1.5 Thread

D2 M12 X 1.75

ODE

Output Signal

G0

G1

4 – 20 mA (Default)

0 – 20 mA (4 wire) (13)

G3 NAMUR NE43 extended 4-20 mA (Burnout 3.55 and 22.8 mA)

CODE

Housing Material (23) (24)

H0

H1

H2

Aluminum (Default) (IP/TYPE)

316 SST – CF8M (ASTM – A351) (IP/TYPE)

Aluminum for Saline Atmosphere (IPW/TYPEX) (18)

H3

H4

316 SST for Saline Atmosphere (IPW/TYPEX) (18)

Copper Free Aluminium (IPW/TYPEX) (18)

CODE

Tag Plate

J0 With tag, when specified (Default) J1 Blank J2 User’s Specification

CODE

PID Configuration

M0 With PID (Default) M1 Without PID

CODE

LCD1 Indication

Y0

Y1

Y2

LCD1: Percentage (Default)

LCD1: Current - mA

LCD1: Pressure (Engineering Unit)

Y3

YU

LCD1: Temperature (Engineering Unit)

LCD1: User’s Specification (14)

CODE

LCD2 Indication

Y0

Y4

Y5

LCD2: Percentage (Default)

LCD2: Current - mA

LCD2: Pressure (Engineering Unit)

Y6

YU

LCD2: Temperature (Engineering Unit)

LCD2: User’s Specification (14)

CODE

Identification Plate

I1

I2

I3

I4

I5

FM: XP, IS, NI, DI

NEMKO: Ex-d, Ex-ia

CSA: XP, IS, NI, DI

EXAM (DMT): Ex-ia

CEPEL: Ex-d, Ex-ia

I6

I7

I8

IF

Without Certification

EXAM (DMT): Class I, M1 Ex-ia

0 to 20 mA: LD301 (13)

CEPEL: Ex-d

CODE

Painting

P0

P3

P4

P5

Gray Munsell N 6.5 Polyester

Black Polyester

White Epoxy

Yellow Polyester

P8

P9

PC

Without Painting

Safety Blue Epoxy – Electrostatic Painting

Safety Polyester - Electrostatic Painting

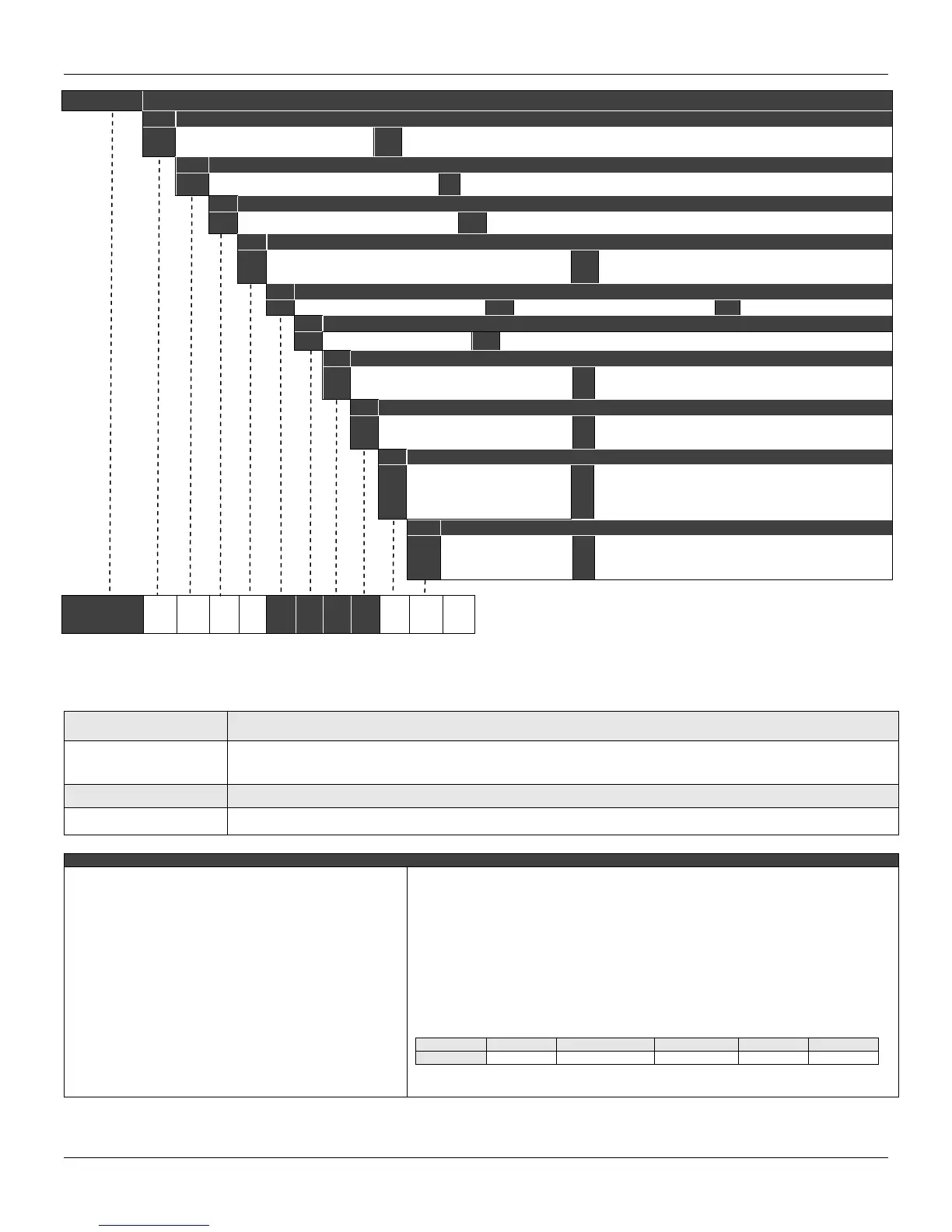

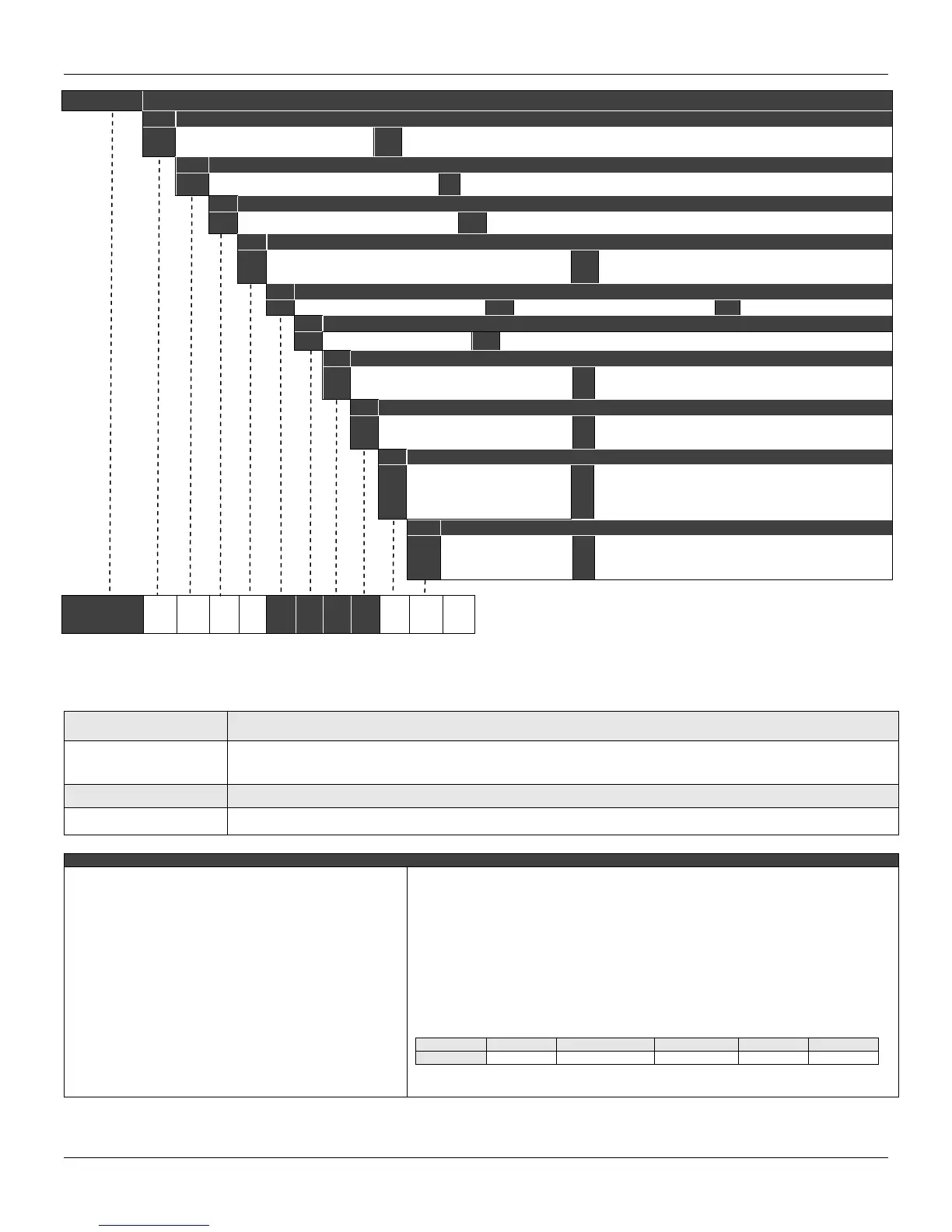

TYPICAL MODEL NUMBER

Optional Items

* Leave it blank when there are not optional items.

Note

(1) Meets NACE MR-01-75/ISO 15156 recommendations.

(2) Silicone oil not recommended for Oxygen (O2) or Chlorine

Service.

(3) Not applicable for vacuum service.

(4) Drain not applicable.

(5) O-Ring material must be of Viton or Kalrez.

(6) Maximum pressure 24 bar.

(7) For remote seal is only available flange in 316 Stainless Steel -

CF8M (ASTM A351) (thread M12).

(8) HP – High Pressure.

(9) Options not certified for hazardous locations.

(10) Not available for Tri-clamp.

(11) Compliant with 3A-7403 standard for food and other

applications where sanitary connections are required:

- Neobee M2O Fill Fluid

- Finishing wet Face: 0,8 µm Ra (32 µ" AA)

- Wet O-Ring: Viton, Buna-N and Teflon

(12) Item by inquiry.

(13) Without certification for explosion proof or intrinsically safe.

(14) Limited values to 4 1/2 digits; limited unit to 5 characters.

(15) Degrease cleaning is not available for Carbon Steel Flanges.

(16) Temperature application range: -40 to 140 °C and Tables 5 and 6 – pages 6.17 and 6.18.

(17) Not applicable for saline atmosphere.

(18) IP66/68W was tested for 200 hours according to NBR 8094 / ASTM B 117 standard.

(19) The inert fluid guarantees safety for Oxygen (O

2

) service.

(20) Certificate for use in Hazardous Locations (CEPEL, NEPSI, NEMKO, EXAM, FM, CSA).

(21) Certificate for use in Hazardous Locations (CEPEL, CSA).

(22) Certificate for use in Hazardous Locations (CEPEL, NEPSI, NEMKO, EXAM).

(23) IPX8 tested in 10 meters of water column for 24 hours.

(24) Ingress Protection:

Product CEPEL NEMKO/EXAM FM CSA NEPSI

LD300 IP66/68W IP66/68W Type4X/6(6P) Type4X IP67

LD301-S21I-

BU10-01A2-

IST12

A0 D0 G0 H0

J0 M0 Y0 Y0 I6 P0 *

Burn-out

BD - Down Scale (Accordance to NAMUR NE43 specification)

BU - Up Scale (Accordance to NAMUR NE43 specification)

Special Procedures

C1 - Degrease Cleaning (Oxygen or Chlorine Service) (15)

C2 - For Vacuum Application

C4 - Polishing of the wet parts according to 3A Certification (11) (12)

Special Features ZZ - User’s Specification

Diaphragm Thickness N0 – Default N1 - 0.1mm (12)

Loading...

Loading...