Technical Characteristics

6.11

MODEL SANITARY PRESSURE TRANSMITTERS

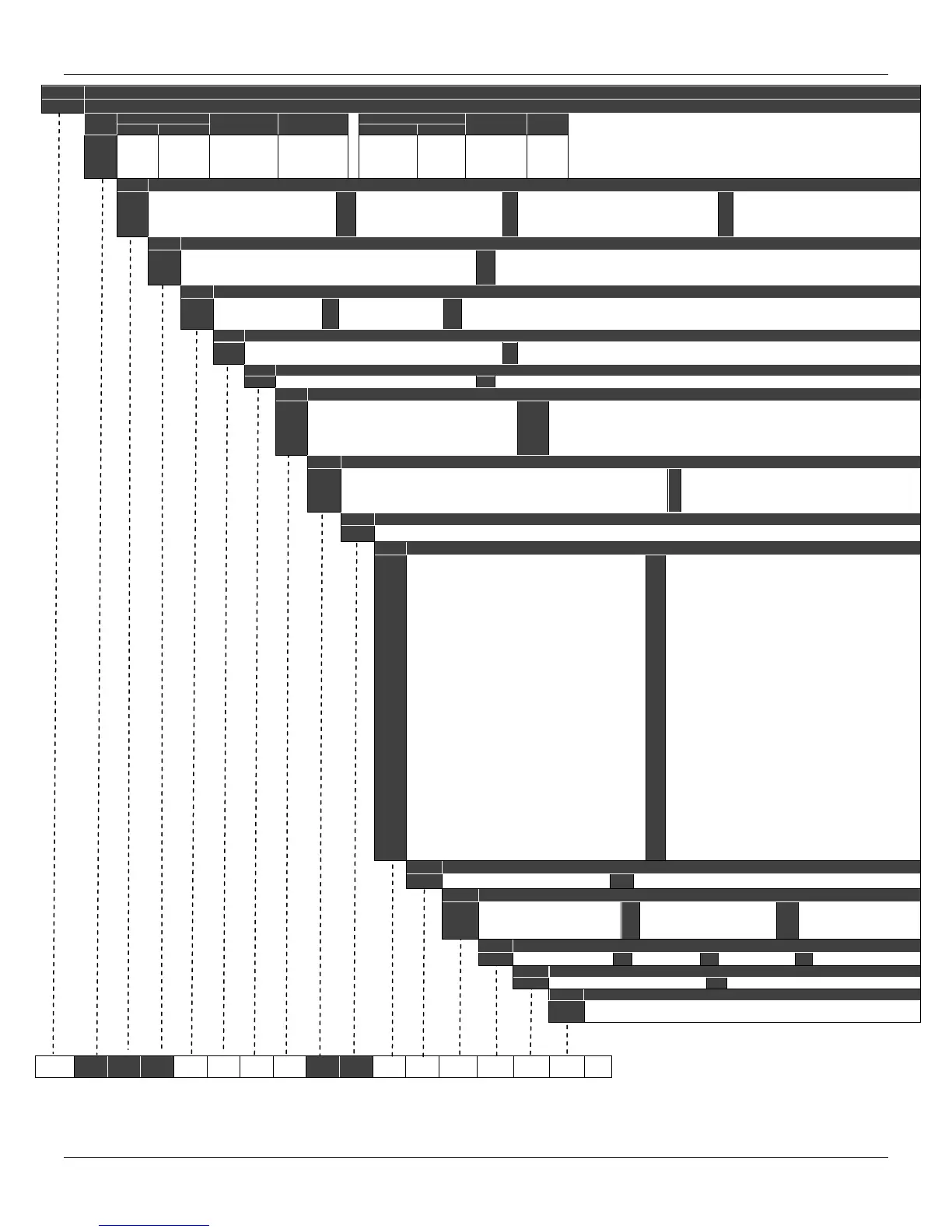

LD301 4-20 mA + HART

CODE Ran

e Limits

Min. Span Unit

Ran

e Limits

Min. Span Unit

Note: The range can be extended up to 0.75 LRL and 1.2 URL with small

degradation of accuracy. The upper range value must be limited to the connection.

Min. Max. Min. Max.

S2

S3

S4

S5

-50

-250

-2500

-25000

50

250

2500

25000

1.25

2.08

20.83

208.30

kPa

kPa

kPa

kPa

-200

-14,7

-14,7

-14,7

200

36

360

3600

0,42

2,08

20,83

0,21

inH

2

O

psi

psi

psi

COD Diaphragm Material and Fill Fluid ( Low Side)

1

2

3

4

5

316L SST

316L SST

Hastelloy C276

Hastelloy C276

Monel 400

Silicone Oil (2)

Inert Fluorolube Oil (3) (19)

Silicone Oil (1) (2)

Inert Fluorolube Oil (1) (3) (19)

Silicone Oil (1) (2)

7

8

9

A

D

Tantalum

Tantalum

316L SST

Monel 400

316L SST

Silicone Oil (2)

Inert Fluorolube Oil (3) (19)

Fomblim Oil

Fomblim Oil (1)

Inert Krytox Oil (19)

E

G

K

M

P

Hastelloy C276

Tantalum

Monel 400

Monel 400 Gold Plated

Monel 400 Gold Plated

Inert Krytox Oil (1) (19)

Inert Krytox Oil (19)

Inert Krytox Oil (1) (19)

Silicone Oil (1) (2)

Inert Krytox Oil (1) (19)

Q

R

S

316L SST

Hastelloy C276

Tantalum

Inert Haloc 4.2 Oil (19)

Inert Haloc 4.2 Oil (1) (19)

Inert Haloc 4.2 Oil (19)

CODE Flange(s), Adapter (s) and Drain Valve(s) Material (Low Side)

C

H

I

Plated CS (Drain in Stainless Steel) (17)

Hastelloy C276 (CW-12MW, ASTM - A494) (1)

316 SST - CF8M (ASTM - A351)

M

N

P

Monel 400 (1)

316 SST – CF8M (ASTM – A351) (Drain in Hastelloy C276) (1)

316 SST – CF8M (ASTM – A351) Flange with PVDF (Kynar) insert (3) (4) (5)

CODE Wetted O-Ring Material (Low Side)

0

B

Without O-Ring

Buna-N

E

K

Ethylene - Propylene

Kalrez

T

V

Teflon

Viton

Note: O-Rings are not available on the sides with remote seal.

CODE

Drain Position (Low Side)

0

A

Without Drain

Drain (Opposite to process connection)

D

U

Bottom

Top

Note: For better drain operation, drain valves are strongly recommended.

Drain valve are not available on the sides with remote seal.

CODE Local Indicato

0 Without Indicator 1 With Digital Indicator

CODE Process Connection (Low Side)

0

1

3

5

9

1/4 - 18 NPT (Without Adapter)

1/2 - 14 NPT (With Adapter)

Remote Seal (With Plug – Vacuum Assembly) (7)

1/2 - 14 NPT Axial with PVDF insert (3) (4) (6)

Remote Seal (Low Volume Flange) (3) (7)

T

U

V

W

1/2-14 BSP (With Adapter)

Low Volume Flange For Level Welded

Without Connection (Mounting With Gage Flange)

Without Connection (Absolut Reference)

CODE Electrical Connection

0

1

2

3

1/2 - 14 NPT (20)

3/4 - 14 NPT (With 316 SST adapter for 1/2 - 14 NPT) (21)

3/4 - 14 BSP (With 316 SST adapter for 1/2 - 14 NPT) (9)

1/2 - 14 BSP (With 316 SST adapter for 1/2 - 14 NPT) (9)

A

B

Z

M20 X 1.5 (22)

PG 13.5 DIN (22)

User’s Specification

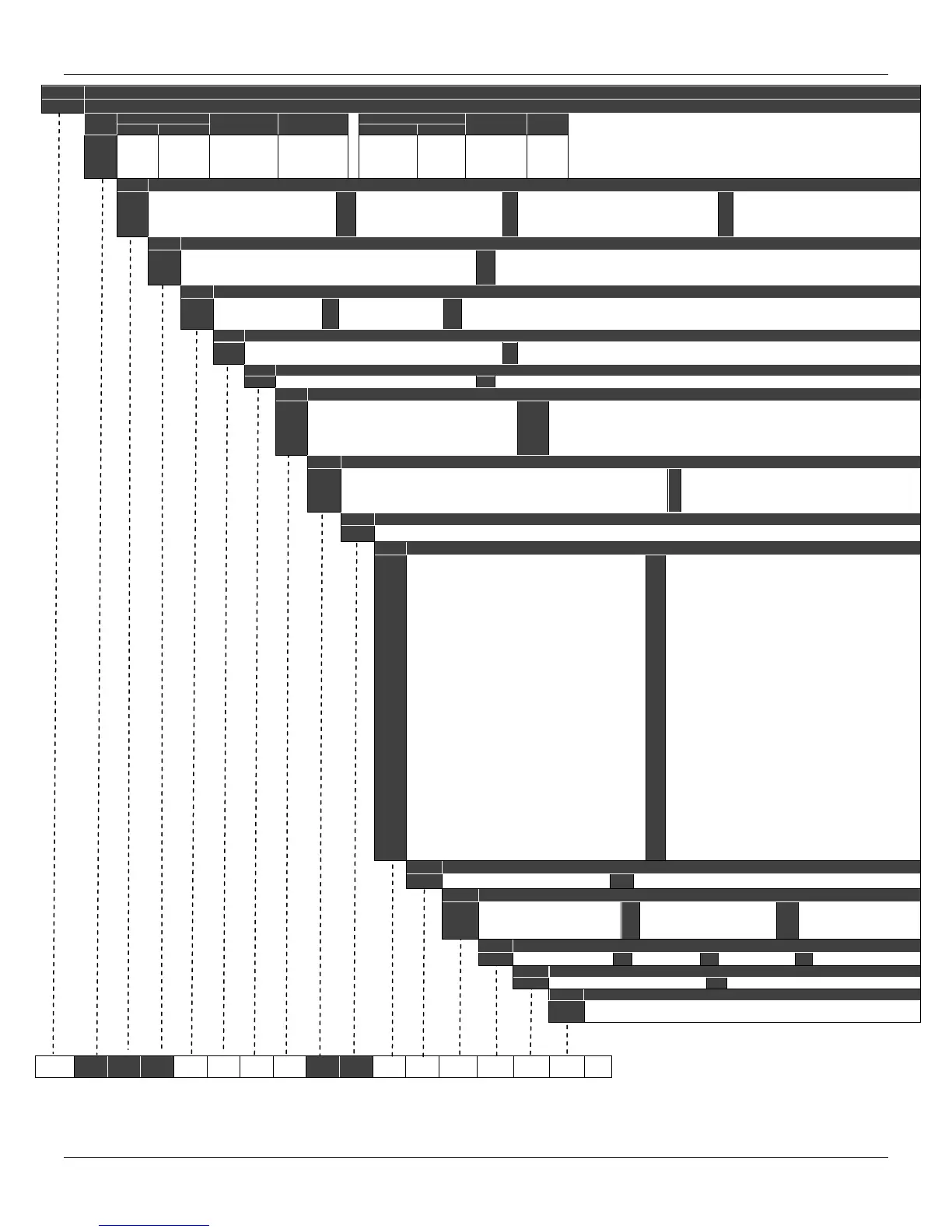

CODE

Zero and Span Adjust

1 With Local Adjustment

CODE

Process Connection

8

9

H

V

U

X

W

4

B

K

3

5

C

L

2

S

Threaded DN25 DIN 11851 – with extension / 316L SST

(10) (11)

Threaded DN40 DIN 11851 - with extension / 316L SST

(10) (11)

Threaded DN40 DIN 11851 – without extension / 316L

SST (10)

Threaded DN50 DIN 11851 - with extension / 316L SST

(10) (11)

Threaded DN50 DIN 11851 - without extension / 316L

SST (10)

Threaded DN80 DIN 11851 - with extension / 316L SST

(10) (11)

Threaded DN80 DIN 11851 - without extension / 316

SST (10)

Threaded IDF 2" - with extension / 316L SST (10) (11)

Threaded IDF 2" – without extension / 316L SST (10)

(11)

Threaded IDF 3" - with extension / 316L SST (10) (11)

Threaded IDF 3" - without extension / 316L SST (10)

(11)

Threaded RJT 2" - with extension / 316L SST (10) (11)

Threaded RJT 2" - without extension / 316L SST (10)

Threaded RJT 3" - with extension / 316L SST (10) (11)

Threaded RTJ 3" - without extension / 316L SST (10)

Threaded SMS 1 1/2" – without extension / 316L SST

(10) (11)

7

E

M

1

F

Q

6

D

N

P

I

G

J

R

Z

Threaded SMS 2" - with extension / 316L SST (10) (11)

Threaded SMS 2" – without extension / 316L SST (10) (11)

Threaded SMS 3" - with extension / 316L SST (10) (11)

Threaded SMS 3" - without extension / 316L SST (10) (11)

Tri-Clamp 1 1/2" – without extension / 316L SST (11)

Tri-Clamp 1 1/2" HP (High Pressure) - without extension /

316L SST (8) (11)

Tri-Clamp 2" - with extension / 316L SST (11)

Tri-Clamp 2" – without extension / 316L SST (11)

Tri-Clamp 2" HP (High Pressure) - with extension / 316L

SST (8) (11)

Tri-Clamp 2" HP (High Pressure) – without extension / 316L

SST (8) (11)

Tri-Clamp 3" - with extension / 316L SST (11)

Tri-Clamp 3" – without extension / 316L SST (11)

Tri-Clamp 3" HP (High Pressure) - with extension / 316L

SST (8) (11)

Tri-Clamp 3" HP (High Pressure) – without extension / 316L

SST (8) (11)

User’s specification

CODE

Diaphragm Material

H Hastelloy C276 I 316L SST

CODE Fill Fluid

S

D

F

DC 200 – Silicone Oil

DC 704 – Silicone Oil

Fluorolube MO-10

T

N

G

Syltherm 800

Neobee M20 (11)

Glycerin + Water (12)

B

K

H

Fomblim 06/06

Krytox 1506

Halocarbom 4.2

CODE Wet O-ring

0 Without O-ring T Teflon (11) B Buna-N (11) V Viton (11)

CODE Tank Adapte

0 Without Tank Adapter 1 With Tank Adapter in 316 SST

CODE Tri-Clamp

0

2

Without Tri-Clamp

With Tri-Clamp in 304 SST

LD301 S2 1 I B U 1 0 0 1 A I S T 1 2 *

TYPICAL MODEL NUMBER

Loading...

Loading...