Maintenance

5.17

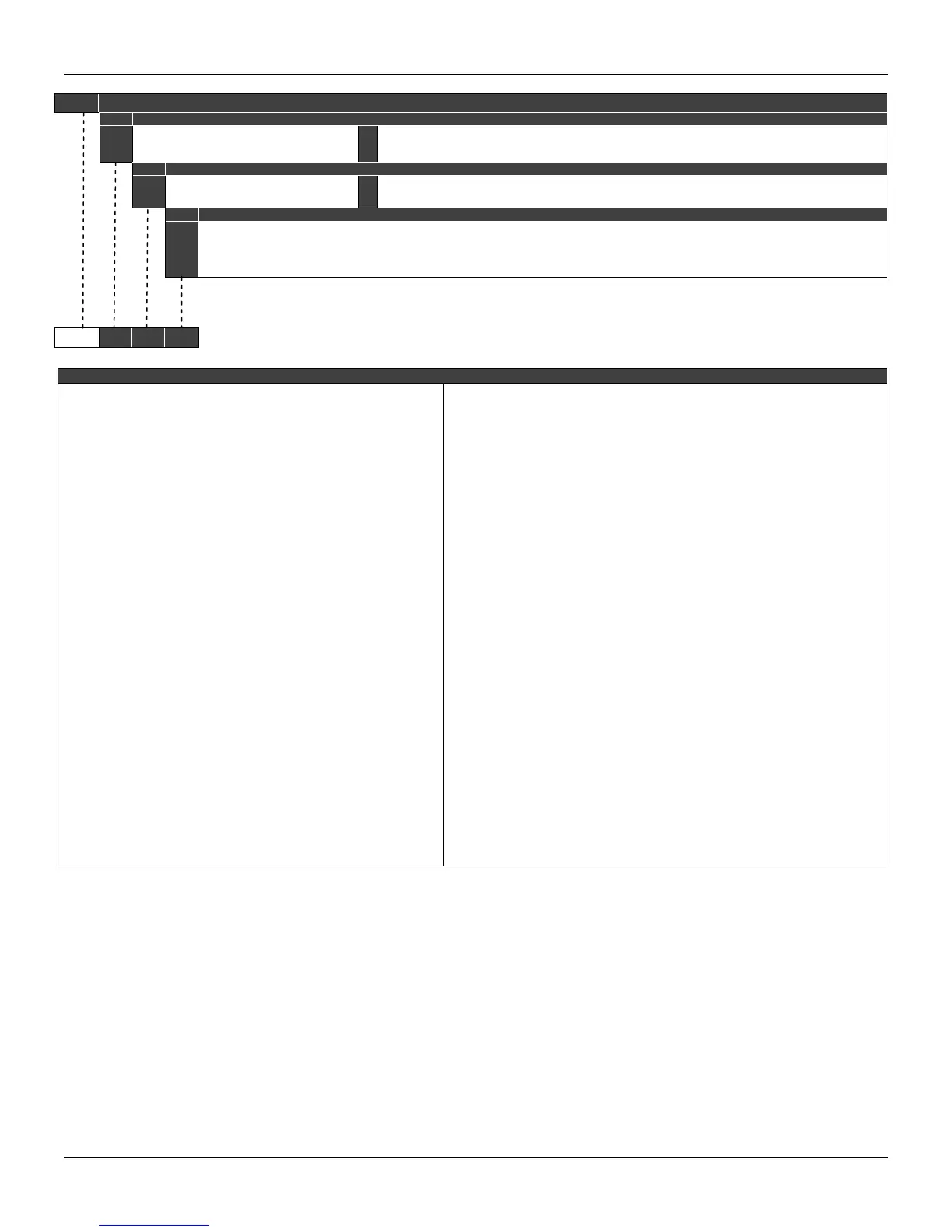

204-0301 SENSOR FOR FLANGED PRESSURE TRANSMITTER (CONTINUATION)

CODE

Flanges Bolts and Nuts Material

A0

A1

A2

Plated Carbon Steel (Default) (22)

316 SST

Carbon Steel (ASTM A193 B7M) (1) (22)

A5

Hastelloy C276

CODE

Flange thread for Fixing Accessories (Adapters, Manifolds, Mounting Brackets, etc)

D0

D1

7/16” UNF (Default)

M10 X 1.5

D2

M12 X 1.75

CODE

Flange Facing Finish

Q0

Q1

Q2

Q3

Q4

Raised Face – RF (Default)

Flat Face – FF

Ring Joint Face – RTJ (Only available for ANSI standard flange) (17)

Tongue Face (11)

Grooved Face (11)

TYPICAL MODEL NUMBER

NOTES

( 1 ) Meets NACE MR – 01 – 75/ISO 15156 recommendations.

( 2 ) Silicone Oils not recommendations for Oxygen (O

2

) or Chlorine

service.

( 3 ) Not applicable for vacuum service.

( 4 ) Drain/Vent not applicable.

( 5 ) O’Ring should be Viton or Kalrez.

( 6 ) Maximum pressure 24 bar.

( 7 ) For remote Seal only 316 SST - CF8M (ASTM A3510 flange is

available (thread M12).

( 8 ) Fluorolube fill fluid is not available for Monel diaphragm.

( 9 ) Options not certified for hazardous locations.

(10) Attention, check corrosion rate for the process, tantalum plate

0.1 mm, AISI 316L extension 3 to 6mm.

(11) Item by inquiry.

(12) Supplied without Gasket.

(13) Without certification for Explosion proof certification or

Intrinsically safe.

(14) Limited values to 4 1/2 digits; limited unit to 5 characters.

(15) Degreaser’s cleaning is not available for carbon steel flanges

(16) The insulator kit is applicable with Raised Face (HO) and

Smooth Face (H1) with Gasket material.

T(Teflon) and only for the following models:

- For models with extension the Gasket T (Teflon) it has special

share.

(17) Gasket for housing, available only in Stainless 316.

(18) Finishing flange faces:

ANSI B 16.5 / MSS-SP6:

- Raised or Smoth Face with gooved lining: 3.2 to 6.3 µm Ra

(125 a 250 µ” AA);

- Small or Large Tongue Face and Small or Large Groove with

smooth finishing not exceeding: 3.2 µm Rt (125 µ” AA);

RTJ ANSI B 16.20 / MSS-SP6:

- Smooth finishing not exceeding: 1.6 µm Rt (63 µ” AA);

DIN EN-1092-1:

- Grooved finishing “B1” (PN 10 a PN40): 3.2 a 12.5 µm Ra (125 a 500

µ” AA);

- Smooth finishing “B2” (PN 63 a PN100), “C” (Tongue) e “D” (Groove):

0.8 a 3.2 µm Ra (32 a 125 µ” AA).

Din 2501 (DIN 2526):

- Smooth finishing “E” (PN 160 a PN250): Rz = 16 (3.2 µm Ra (125 µ”

AA).

Standard Jis B2201

- Grooved finishing 3.2 a 6.3 µm Ra (125 a 250 µ” AA).

(19) Range of application of temperature from -40 ºC to 150 ºC.

(20) Applicable only to:

- Thickness of steel: 0.05 mm

- Diameter/capillary length:

2” ANSI B 16.5 DN 50 DIN, JIS 50 A, for seals up to 3 meters of

capillary and level models (by inquiry).

3” ANSI B 16.5 DN 80 DIN, JIS 80 A, for seals up to 5 meters of

capillary and level models.

- Faces: RF and FF;

- Temperature Range: +10 to 100 ºC

+ 101 to 150 ºC (by inquiry)

- Not applicable for diaphragm thickness;

- Not applicable for use with gaskets.

(21) Inert Fluid: Oxygen Compatibility, safe for oxygen service.

(22) Not applicable for saline atmosphere.

(23) Not available for slip-on flange.

(24) Not available for integral flange.

204-0301 A0 D0 Q0

Loading...

Loading...