Chapter 9 - Tips and tricks for cable testing

Copyright 2016 Softing Industrial Automation GmbH

45

The BC-700-PB uses amongst other methods impulse reflectometry for assessing the cabling and

classifying and locating errors on the cable. Multiple cable errors, which exist simultaneously on the

cable may result in an imprecise cable test result. The more the corrective repair of the cable is

proceeding, the more precise the cable test results in the corresponding PROFIBUS cable segment will

be.

Electromagnetic interferences may influence PROFIBUS cable testing in a negative manner because

cable conductors may act like an antenna. Consider this aspect during cable testing and take care of

proper functional earthing of your plant respectively. Existing high frequency noise voltage may

negatively influence the BC-700-PB if operated by means of the external power supply. We recommend

operating on the BC-700-PB by means of the built-in battery under the above mentioned prevailing

conditions.

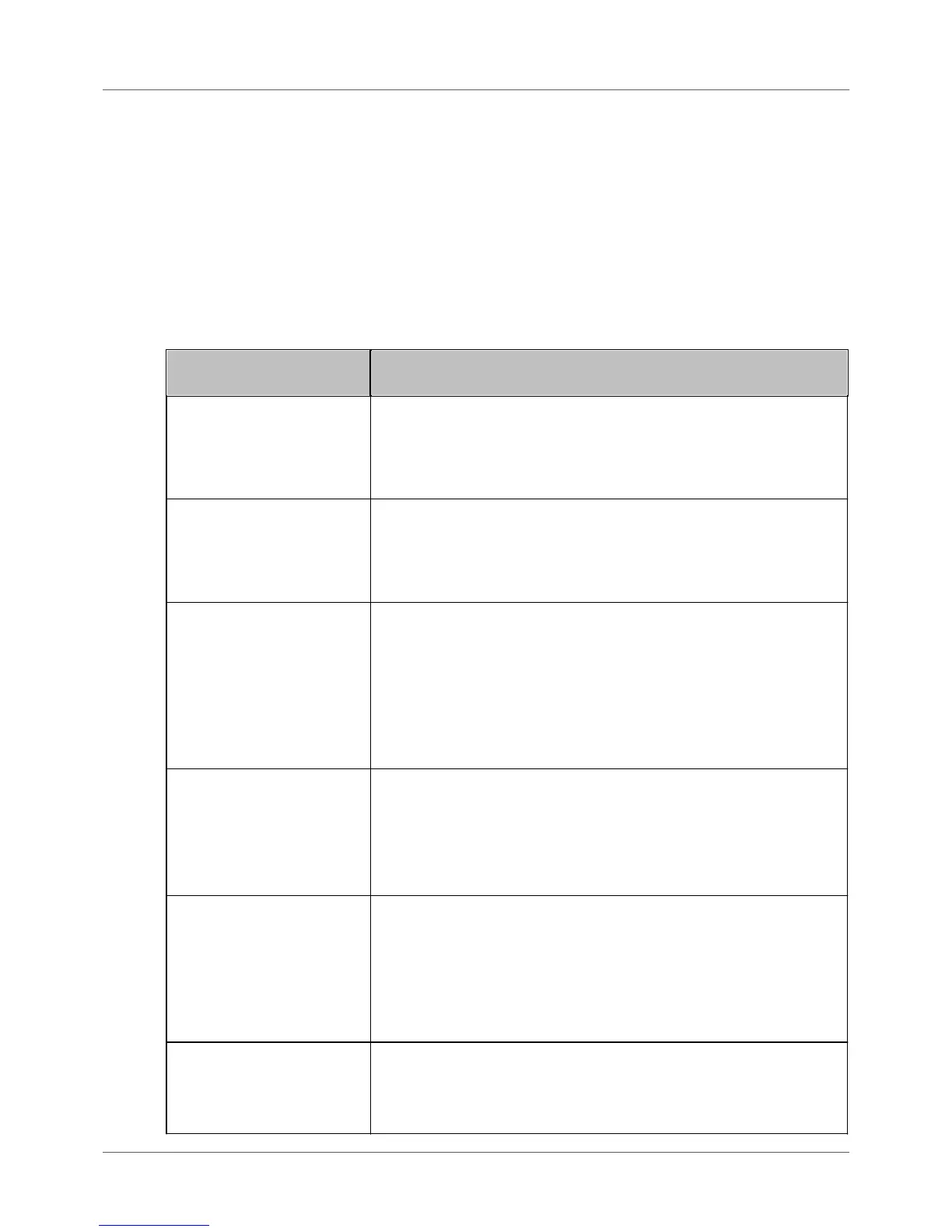

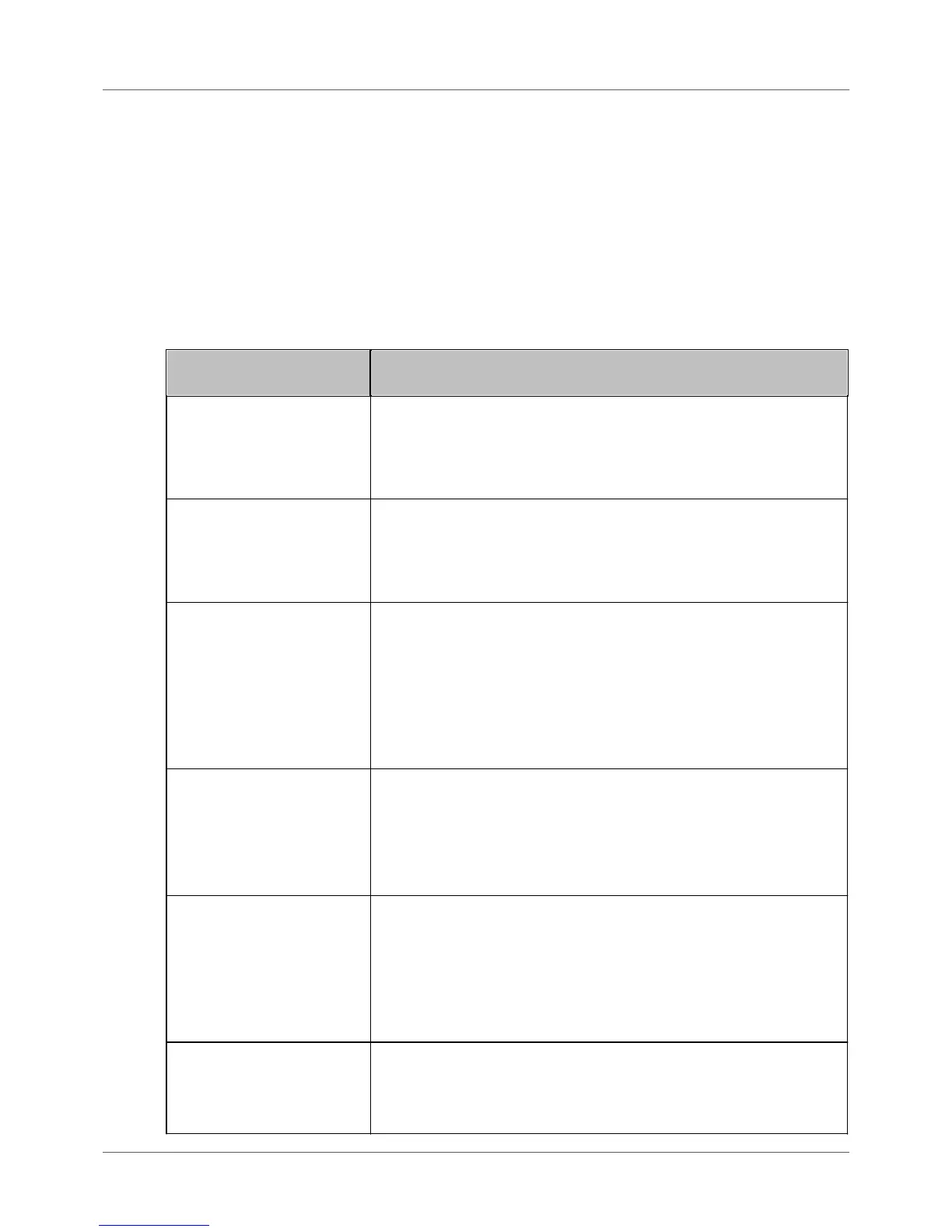

Cable testing error message

displayed on BC-700-PB

Remedial measures - starting points for correctly interpreting and

repairing the indicated fault

The green signal line of the PROFIBUS-cable is broken. Search for

damage on the cable in the vicinity of the indicated error location.

Fatigue breakage or a faultily assembled PROFIBUS-connector may

cause this error. The green signal line typically is connected to Pin 8 of

the PROFIBUS Sub-D type connector.

The red signal line of the PROFIBUS-cable is broken. Search for damage

on the cable in the vicinity of the indicated error location. Fatigue

breakage or a faultily assembled PROFIBUS-connector may cause this

error. The red signal line typically is connected to Pin 3 of the

PROFIBUS Sub-D type connector.

The shielding conductor is broken in the tested cable segment.

Alternatively electromagnetic shielding is not applied for in a

continuous manner. Search for damage on the cable in the vicinity of

the indicated error location. Fatigue breakage or a faultily assembled

PROFIBUS-connector may cause this error.

In rare cases electromagnetic shielding may be disrupted intentionally

in order to avoid electromagnetic interferences. Check this issue with

the planning personnel of the PROFIBUS-facility.

Short circuit between A and B

There is an unusual low ohmic or capacitive resistance between signal

lines A and B. Search for damage on the cable in the vicinity of the

indicated error location. A severe crush of the cable or multiple

unpowered bus terminators may cause this error.

In addition search for illegal spur lines and check, if moisture

penetrated the cabling or if the cabling is heavily soiled.

Short circuit between A and

shield

Short circuit between B and

shield

Short circuit between A, B

and shield

There is an unusual low ohmic or capacitive resistance between the

mentioned signal lines and conductors. Search for damage on the cable

in the vicinity of the indicated error location. A severe crush of the

cable or a faultily assembled PROFIBUS-connector may cause this

error.

In addition search for illegal spur lines and check, if moisture

penetrated the cabling or if the cabling is heavily soiled.

Capacitive Load / Spur Line

There is an unusual capacitive load between signal lines A and B and

the shield conductor. An illegal spur line or interference-suppression

capacitors may cause this error. This is common usage with "over-

compensated" or defective PROFIBUS-devices.

Loading...

Loading...