PROFIBUS Tester 5 (BC-700-PB) - User Manual

46

Copyright 2016 Softing Industrial Automation GmbH

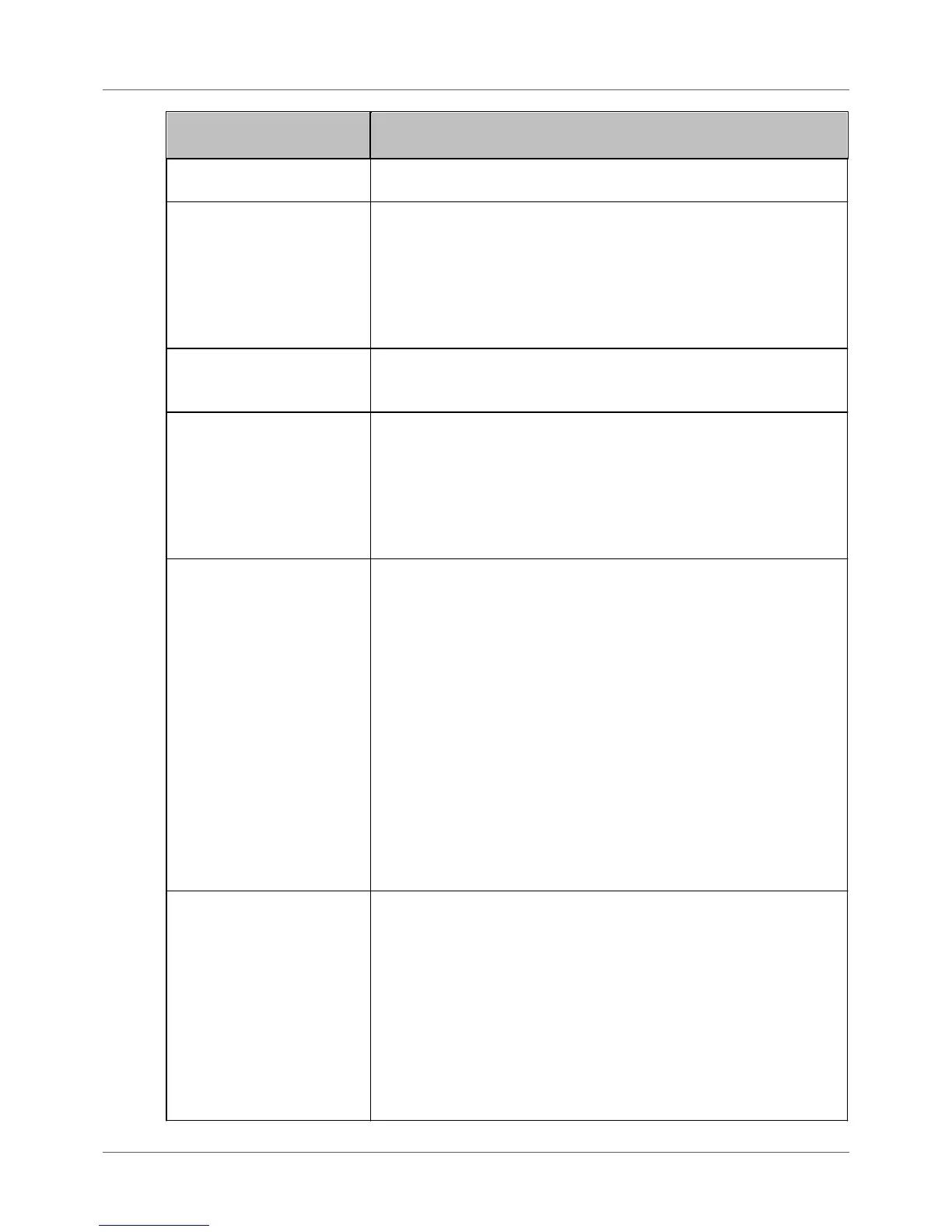

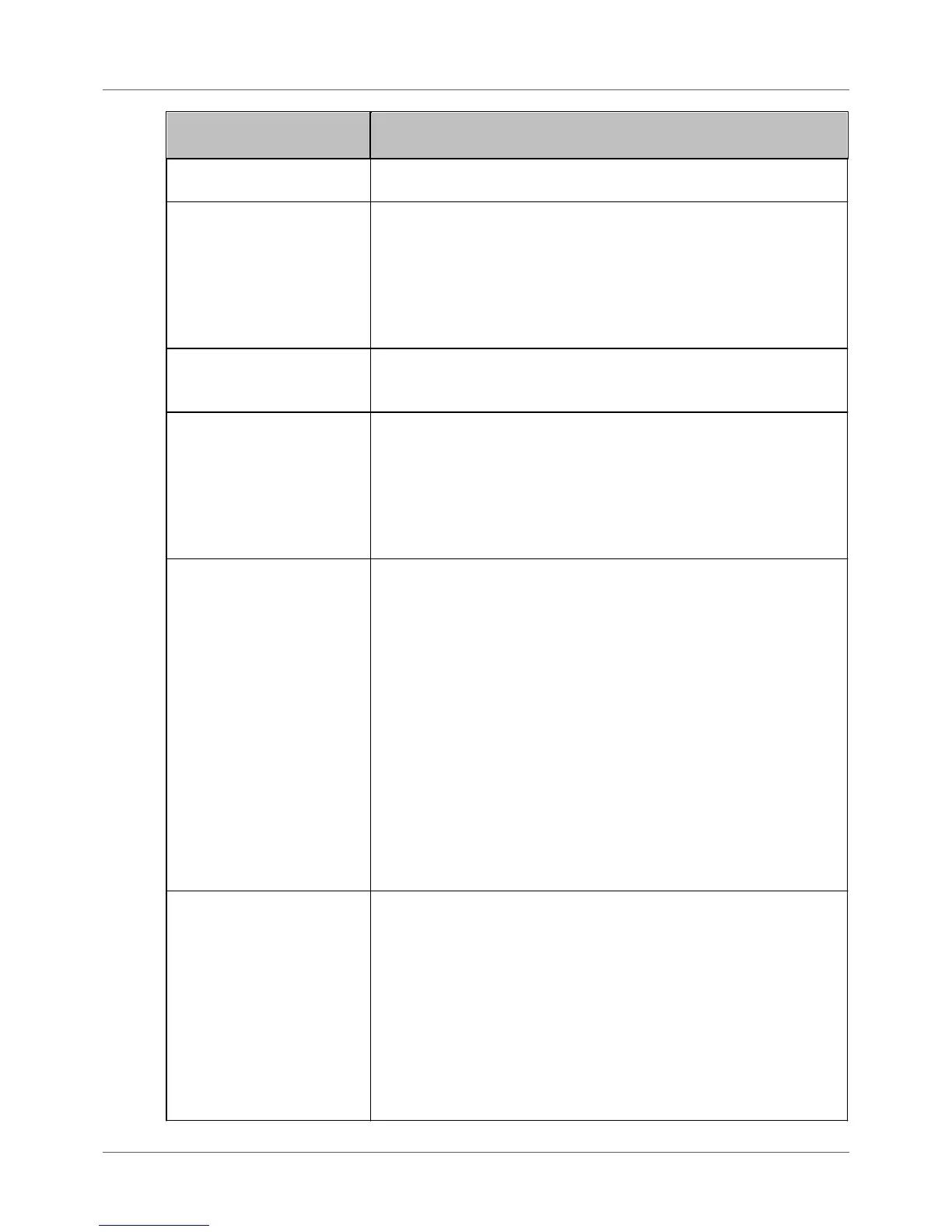

Cable testing error message

displayed on BC-700-PB

Remedial measures - starting points for correctly interpreting and

repairing the indicated fault

Disconnect the devices in the vicinity of the indicated error location

and repeat cable testing in order to narrow down the error cause.

The cable is still affected by unwanted reflections. Though it is not

possible to classify the fault indication. Search for damage on the cable

in the vicinity of the indicated error location and make sure the

PROFIBUS-connectors are assembled correctly.

Unwanted reflections may emerge from transitions between media

and signal conductors which have different impedance values (e.g. two

different cable types).

Sending pulse could not be

detected. The cable is either

too short or not connected.

Do not fall below the minimum cable length of 3 meters. The intended

use of cable testing requires a cable with adequate length.

(Near-end) terminator

switched on

No reflections could be

detected. Please remove

terminators.

During the first of the three steps of cable testing the PROFIBUS Tester

requires an open cable on both sides. However, the tester detected an

ohmic resistance between the signal wires and the resistance value is

in the range of bus terminators. Make sure, that every bus terminator

on every PROFIBUS-connector is switched off or is deactivated.

Check the dip-switch for switching on/off bus terminators for proper

function.

The ideal idle voltage between signal wires A and B of a cable segment,

which is properly terminated on both sides is approximately 1.1 Volts.

The PROFIBUS-Tester detected voltage values higher than 3 Volts

between the signal wires A-B; A-Shield and/or B-Shield. These

unwanted potential differences obstruct the cable testing function, the

test results will become void and running leakage currents may

damage the PROFIBUS-Tester.

Take care of proper functional earthing of your plant.

We recommend removing the mains adapter and to operate on the

BC-700-PB by means of the built-in battery if you are receiving this

error message. This will avoid damage caused by leakage currents.

Take also into consideration that the error cause could be a defective

RS-485 driver of a PROFIBUS-device. Troubleshooting EMC and

earthing issues are a highly complex field of activity. Therefore we

recommend asking service providers which are primarily specialized in

troubleshooting the above mentioned issues.

Far-end / Near-end

terminator not powered.

The corresponding bus terminator has been switched on, but the

terminator is improperly powered by 5 V supply voltage, yet.

During the cable testing the PROFIBUS Tester requires a properly

terminated cable at the far end (2nd test step) or on both sides of the

cable segment (3rd test step). A properly terminated cable segment

consists of activated and powered bus terminators on both sides of the

cable.

Make sure that the corresponding PROFIBUS-device at the

corresponding end of the cable segment is powered and that th

activated bus terminator is properly plugged to a powered PROFIBUS-

device.

Loading...

Loading...