TS 410, TS 420

English

16

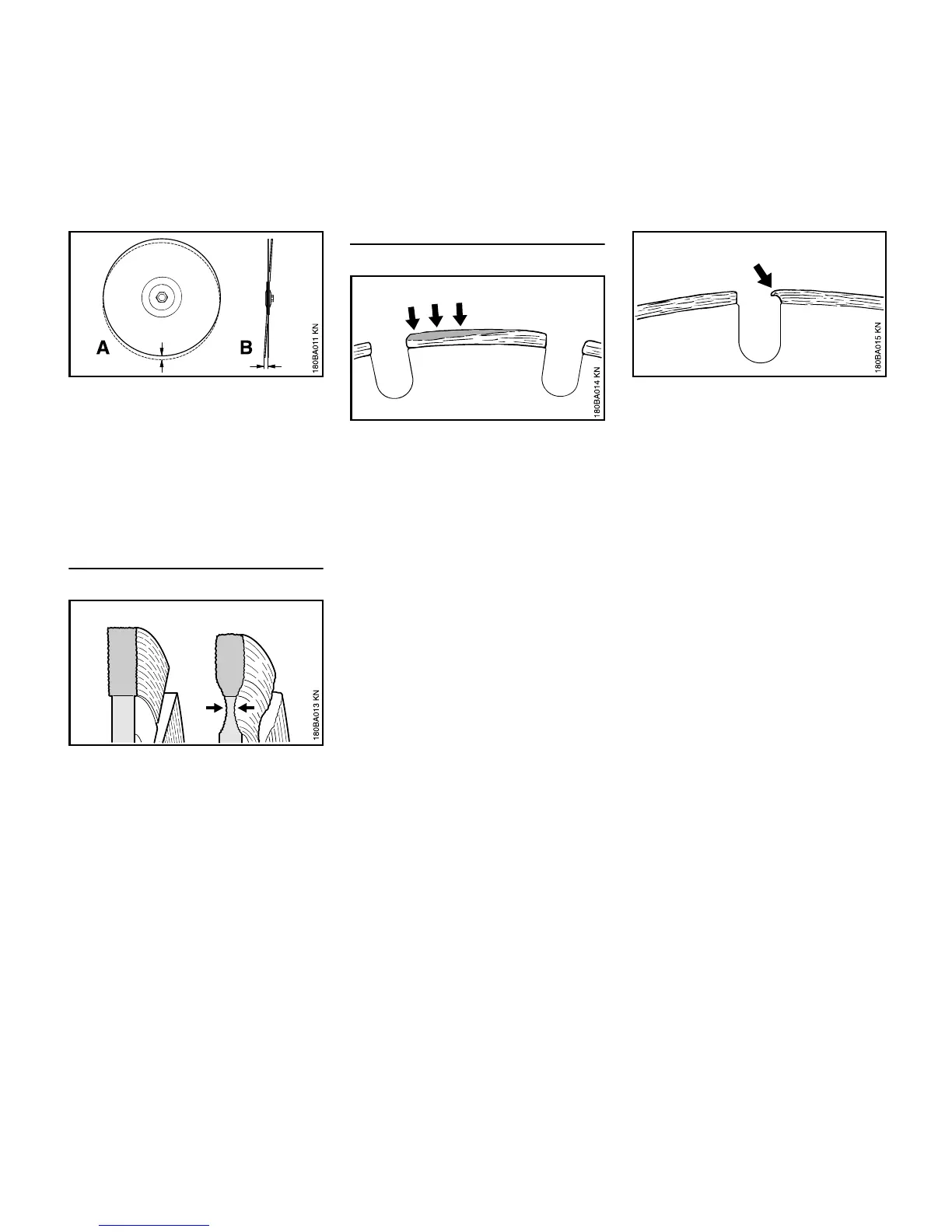

An excessively high radial run-out

deviation(A) overloads individual

diamond segments, which overheat in

the process. This can lead to stress

cracks in the parent wheel or to

annealing of individual segments.

Deviations in axial run-out(B) result in

higher thermal loading and wider cuts.

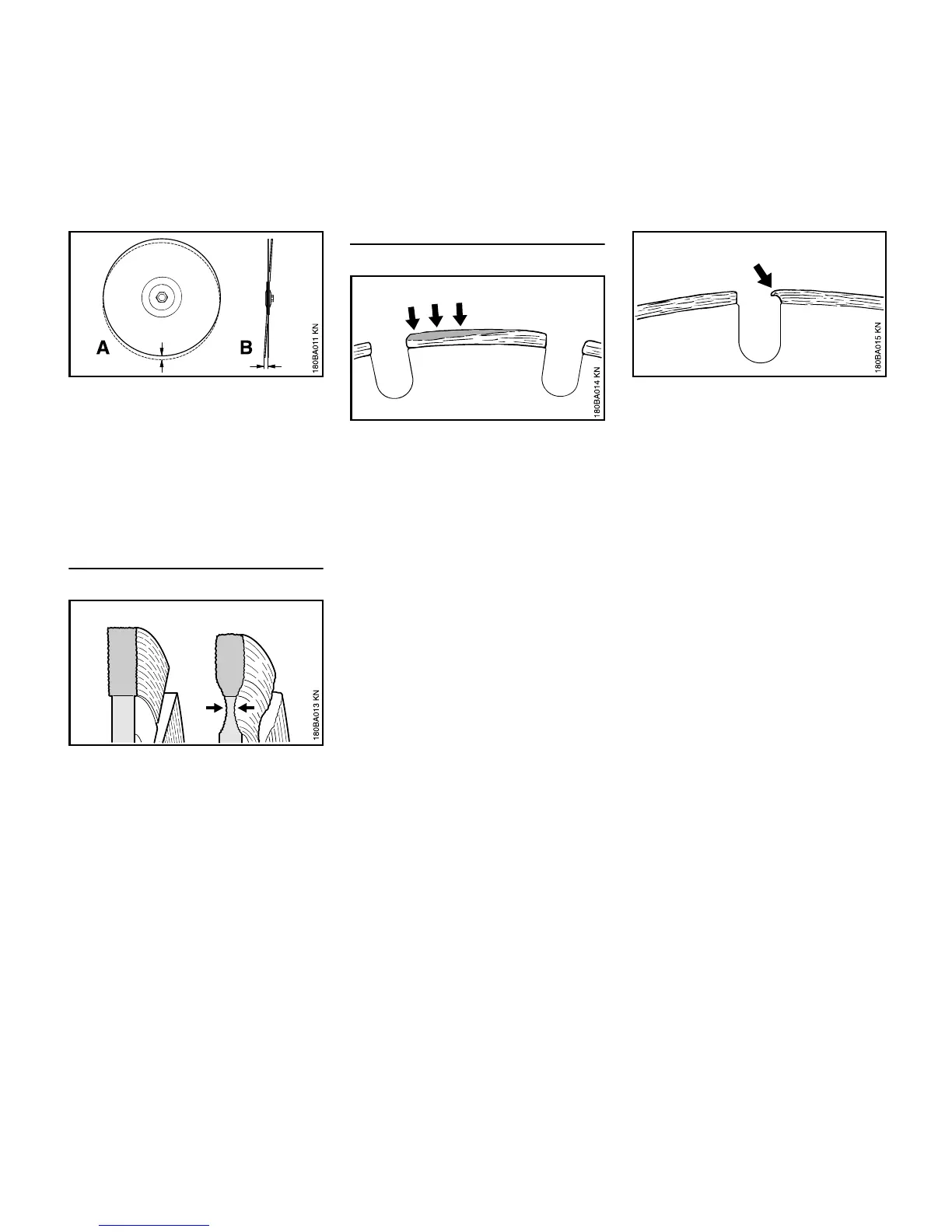

Undercut

Do not cut into the base course

(frequently chipped stones and gravel)

when cutting roadway pavement –

cutting in chipped stones and gravel is

revealed by light-colored dust –

excessive undercut may occur as a

result – Danger of shattering!

Built-up edges, sharpen

Built-up edges take the form of a light

gray deposit on the tops of the diamond

segments. This deposit on the segments

clogs the diamonds and blunts the

segments.

Built-up edges can form:

– when cutting extremely hard

materials, e.g., granite

– with incorrect handling, e.g.,

excessive feed effort

Built-up edges increase vibration,

reduce cutting performance, and cause

formation of sparks.

At the first signs of built-up edges,

immediately "sharpen" the diamond

abrasive wheel – to do this, briefly cut

through abrasive material such as

sandstone, aerated concrete or asphalt.

Addition of water prevents the formation

of built-up edges.

If work continues with dull segments,

these may soften due to the high heat

generated – the parent wheel is

annealed and its strength is

compromised – this can lead to stresses

that are clearly recognizable by

gyrations of the abrasive wheel. Do not

continue to use the abrasive wheel –

Risk of accident!

Loading...

Loading...