TS 410, TS 420

English

17

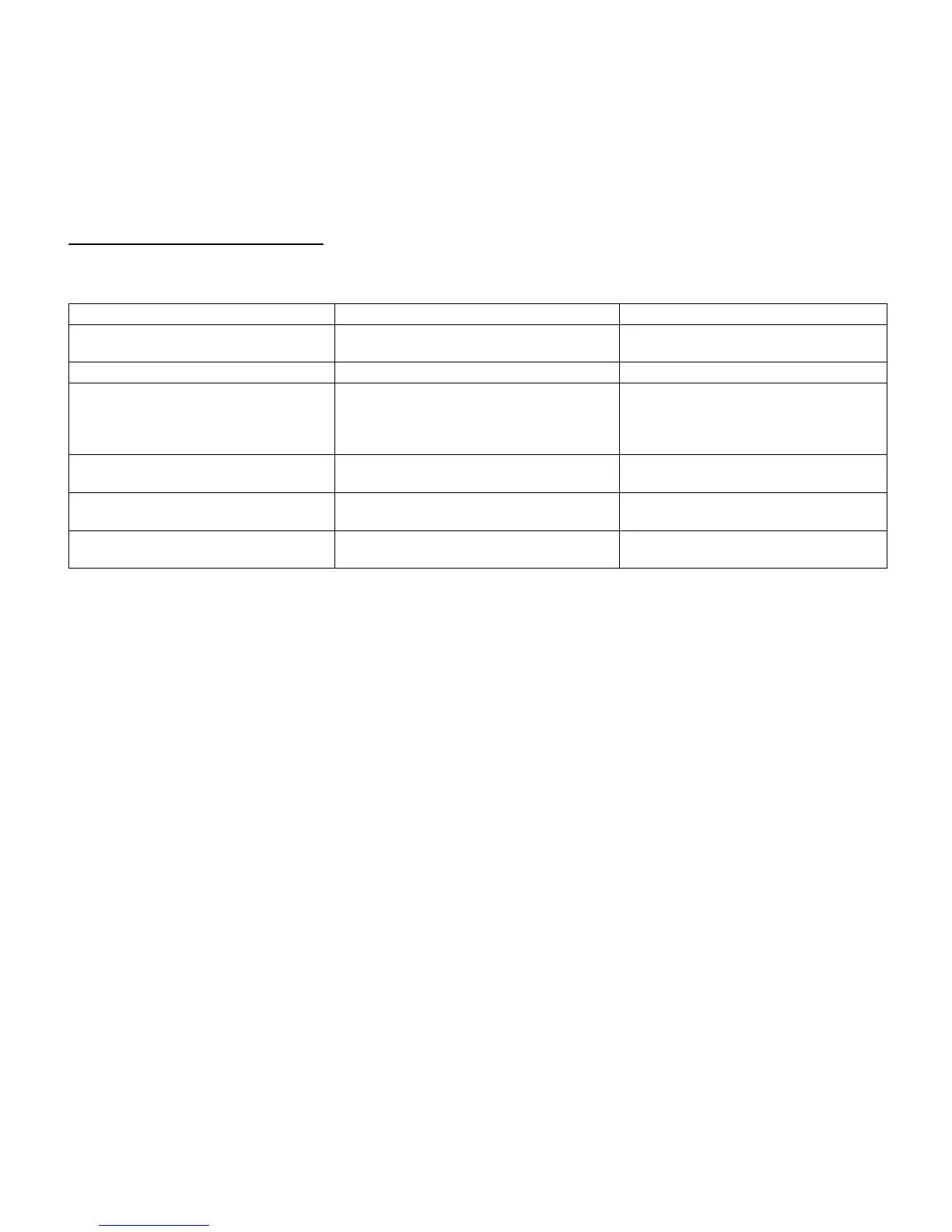

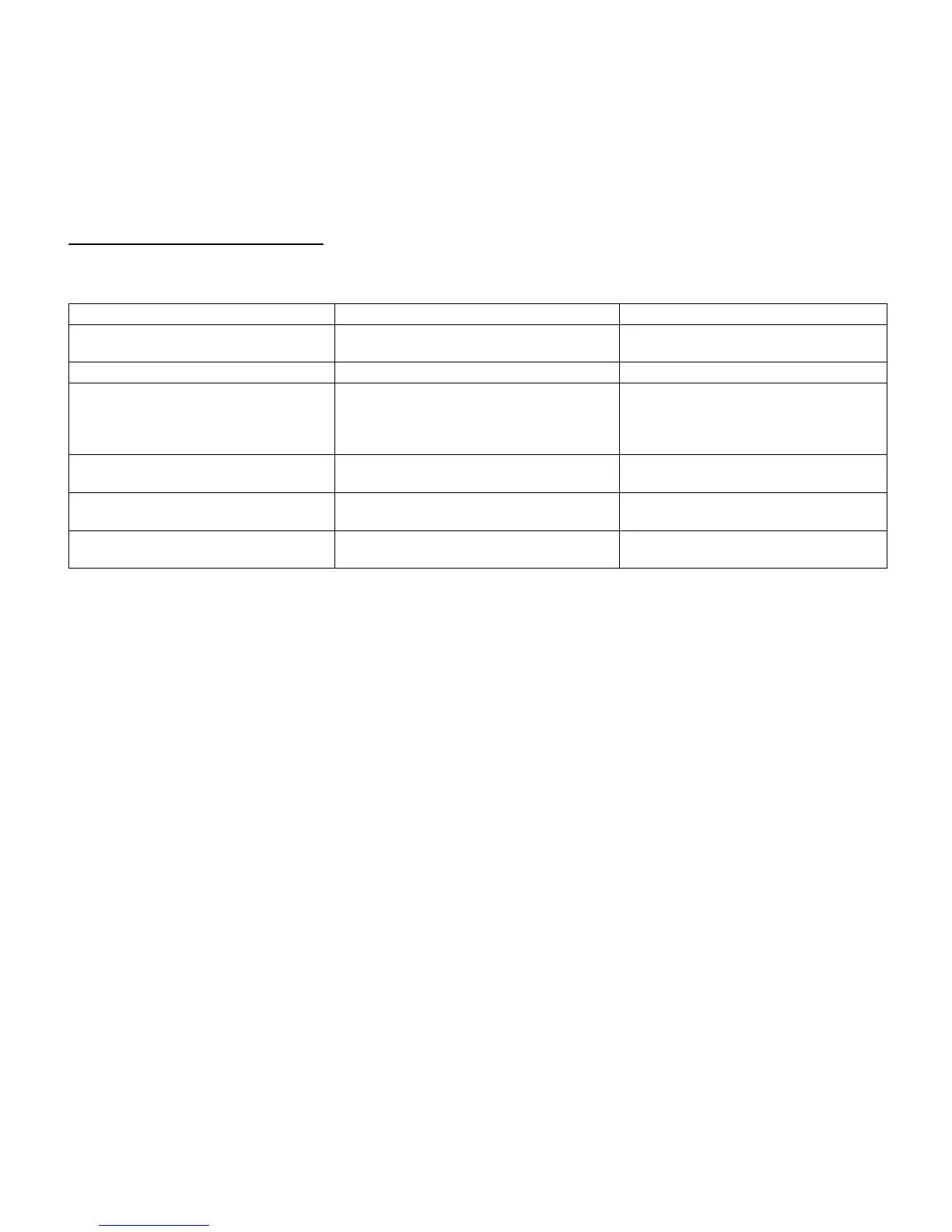

Troubleshooting

Abrasive wheel

Defects Cause Remedy

ragged edges or cut surfaces, crooked

cut

Deviation in radial or axial run-out Contact a servicing dealer

1)

heavy wear on the sides of the segments Abrasive wheel gyrates use a new abrasive wheel

ragged edges, crooked cut, no cutting

performance, generation of sparks

Abrasive wheel is dull; built-up edges with

abrasive wheels for stone

Sharpen abrasive wheels for stone by

briefly cutting through abrasive materials;

replace abrasive wheel for asphalt with a

new one

poor cutting performance, high segment

wear

Abrasive wheel is turning in the wrong

direction

Mount abrasive wheel so that it turns in

the right direction

Breakdowns or tears in the parent wheel

and segment

Overloading use a new abrasive wheel

Undercut Cutting in the wrong material use new abrasive wheel; observe sepa

-

rating layers of various materials

1)

STIHL recommends STIHL servicing dealers

Loading...

Loading...