46 TS 410, TS 420

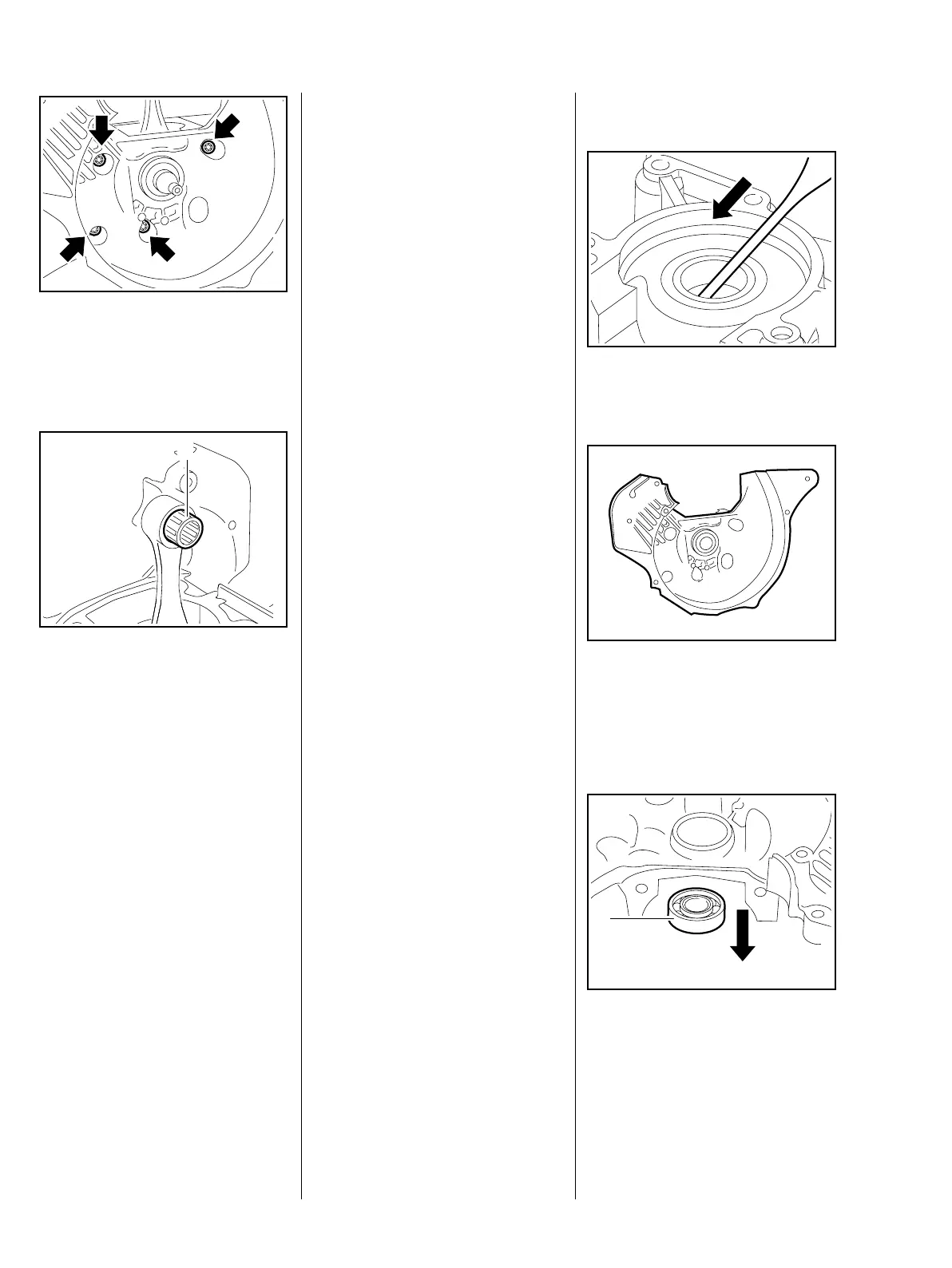

: Insert the screws (arrows) and

tighten them down crosswise.

– Tightening torques, b 3.5.

– Coat the needle bearing (1) with

oil.

: Slide the needle bearing (1) into

the small end.

– Examine and install the piston,

b 7.7.

– Examine and install the cylinder,

b 7.5.

– Reassemble remaining parts in

reverse order.

370RA136 TG370RA161 TG

1

7.6.2 Grooved ball

bearing / crankcase

The two halves of the crankcase

can be replaced individually if they

are defective.

New crankcases are delivered with

the relevant components pre-

assembled – see spare parts list.

Those parts which are not supplied

with the new crankcase must be

removed from the old crankcase,

examined and replaced if

necessary.

When fitting a new crankcase, the

machine's serial number must be

stamped on the crankcase with

2.5 mm figure stamps.

If the original crankcase is reused,

the oil seals and grooved ball

bearings must be replaced, all

gasket residues removed and the

mating surfaces cleaned

thoroughly. The mating surfaces

must be absolutely clean to

guarantee a perfect seal.

Examine both halves of the

crankcase for cracks and check all

mating surfaces for signs of

damage.

– Refer also to troubleshooting,

b 4.6.

– Remove the crankshaft,

b 7.6.1.

– Wear protective gloves – risk of

burns.

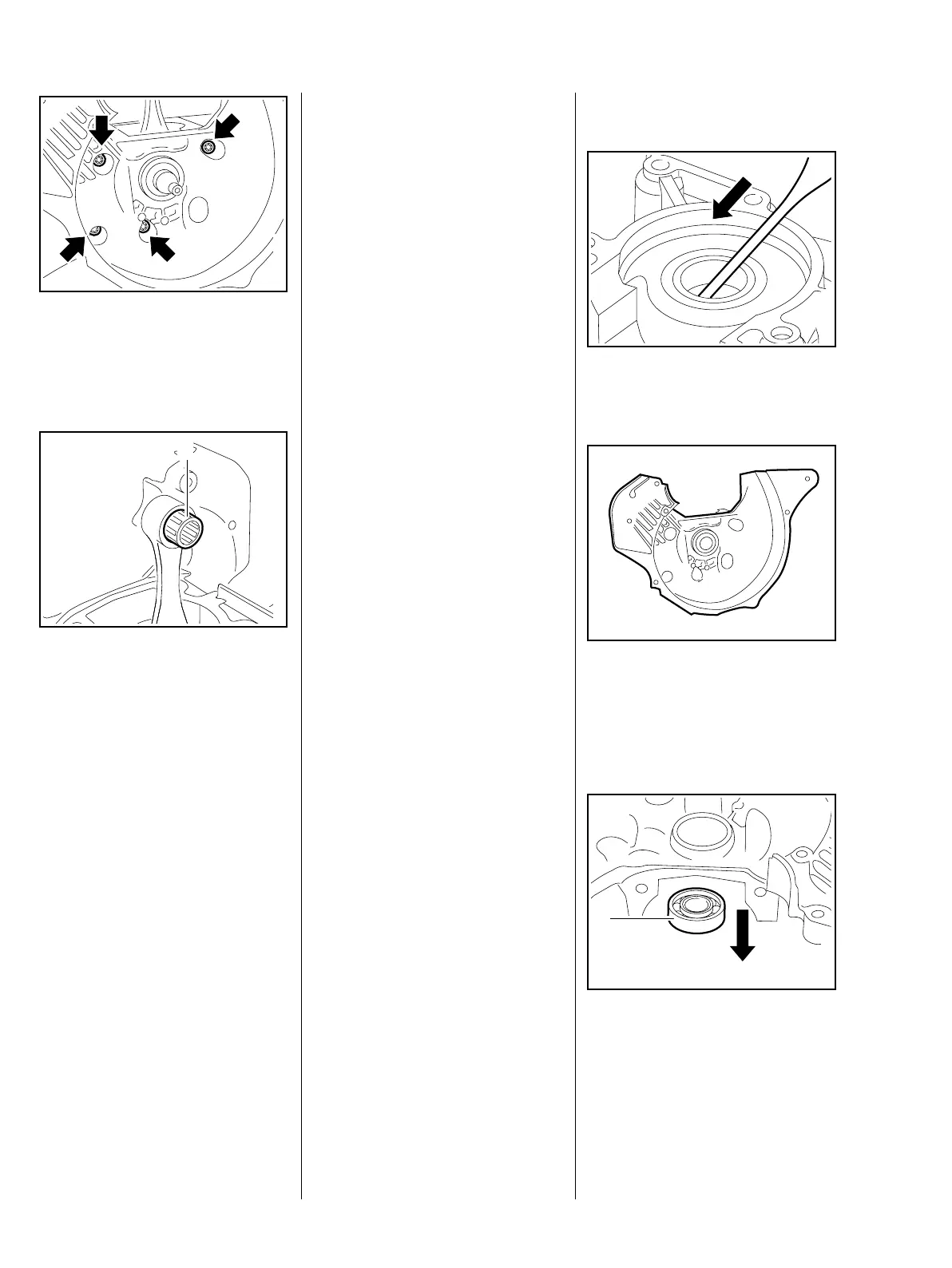

Ignition-side half of the

crankcase

: Carefully drive the oil seal out

with a suitable punch.

: Examine and clean the

crankcase, replace if necessary.

Fit new grooved ball bearings if the

crankcase is in good condition.

– Heat the area around the bearing

seat to approx. 150 °C (300 °F).

The bearing (1) drops out of its own

accord when this temperature is

reached.

370RA162 TG370RA163 TG370RA164 TG

1

Loading...

Loading...