79TS 410, TS 420

12.2.1 Leakage testing

The tank vent must also be checked

and replaced if problems develop

with the carburetor or fuel supply,

b 12.7.

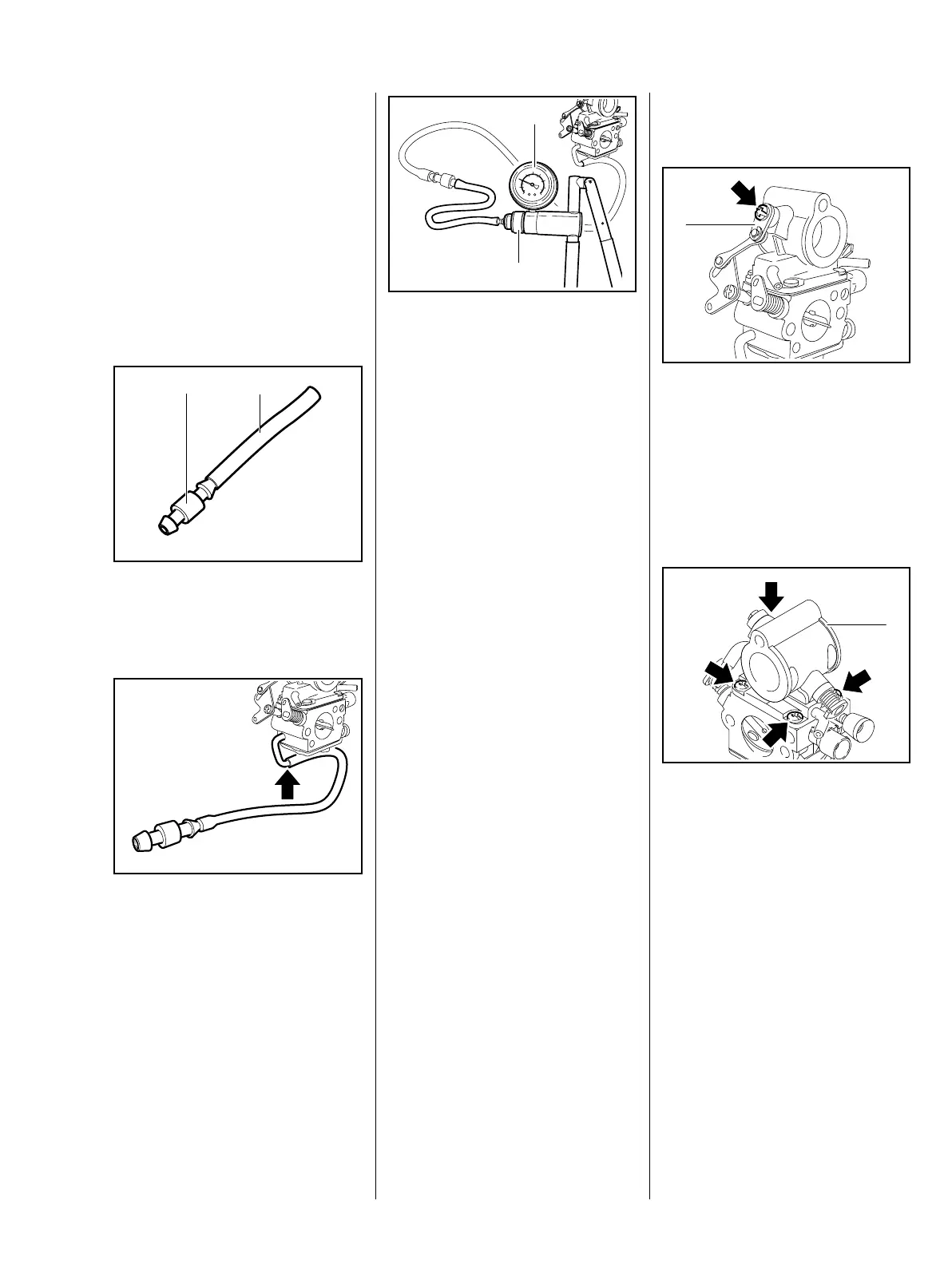

The carburetor can be tested for

leaks with the pump

0000 850 1300.

– Remove the carburetor, b 12.2.

: Push the fuel line (1)

1110 141 8600 onto the double

connector (2) 0000 855 9200.

: Push the fuel line with double

connector onto the fuel port

(arrow).

VA

143RA172

2 1

370RA331 TG

– Push the delivery hose of the

pump 0000 850 1300 onto the

double connector.

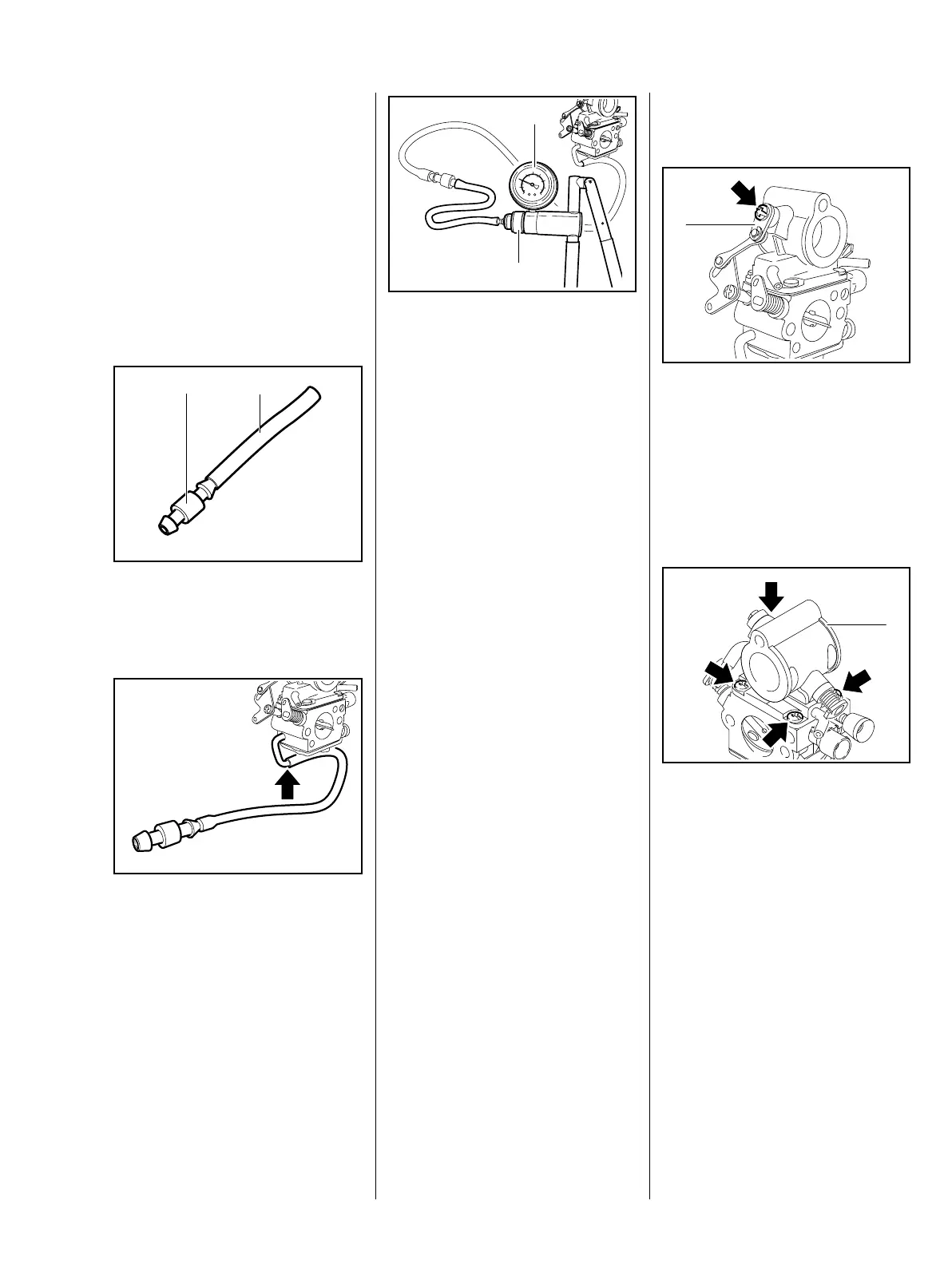

: Push ring (1) to the right and

pump air into the carburetor until

the pressure gauge (2) shows

a pressure of approx. 0.8 bar

(80 kPa).

If this pressure remains constant,

the carburetor is airtight. However,

if the pressure drops, there are two

possible causes:

1. The inlet valve is not sealing

(impurities in the valve seat,

sealing cone of the inlet needle

is damaged or inlet control lever

is sticking). Remove to clean,

b 12.3.2.

2. Metering diaphragm or gasket is

damaged, replace if necessary,

b 12.3.1.

3. Pump diaphragm or gasket is

damaged, replace if necessary,

b 12.3.4.

– After testing, push the ring (1) to

the left to vent the pump, then

disconnect the fuel line from the

connector on the carburetor.

– Install the carburetor, b 12.2.

– Reassemble remaining parts in

reverse order.

– Tightening torques, b 3.5.

1

2

370RA332 TG

12.3 Repairing the carburetor

12.3.1 Metering diaphragm

– Troubleshooting, b 4.5.

– Remove the carburetor, b 12.2.

: Remove the screw (arrow).

– Remove the lever (1).

: Take out the screws (arrows).

– Remove the end cover (1).

If the gasket and diaphragm are

stuck to the carburetor, they must

be removed very carefully.

370RA333 TG

1

370RA334 TG

1

Loading...

Loading...