82

Item Check method

Air inlet and outlet

Check the temperature of the heat sink and the amount of dust

accumulated. Clean heat-dissipation modules with a vacuum

cleaner if necessary.

Device maintenance

• Carry out regular inspection for corrosion of all metal

components.

• Check the contactor to ensure a normal mechanical

operation.

• Check the operation parameters (especially voltage and

insulation).

The recommended routine maintenance periods in the table are only for reference.

The actual maintenance period shall be determined reasonably in consideration

of the specific installation environment of the product.

Power plant scale, location, site environment, and other factors also affect the

maintenance period of the product. It is necessary to shorten the maintenance pe-

riod and increase the maintenance frequency in the event of a heavy sandstorm

or dust in the operating environment.

11.3 Common Maintenance Items

It is recommended to clean the inverter once every six months. If the inverter works in harsh

environments, such as desert areas, the maintenance cycle should be shortened.

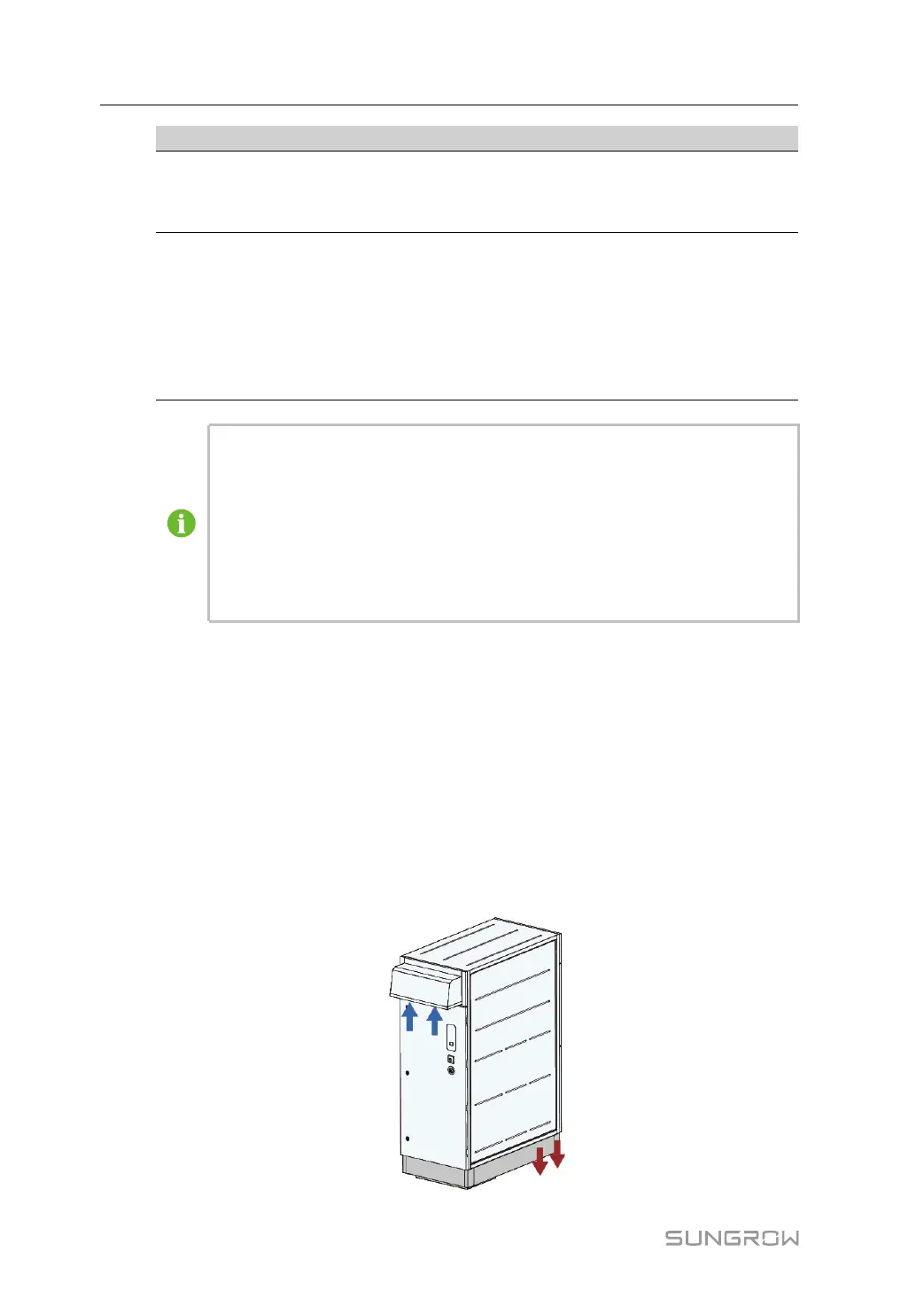

11.3.1 Cleaning Air Inlet of Inverter

Overview

The following figure shows the heat dissipation mode of the inverter. The air inlet is located

at the higher parts of the DC cabinet while the air outlet is located at the lower parts of the

AC cabinet.

11 Routine Maintenance System Manual

Loading...

Loading...