INSTALLATION AND TRANSPORT

MJB4 - Installation and Transport Rev07 05-10 7

2

2. INSTALLATION AND TRANSPORT

Containers must be opened and the machine must

be transported and installed by a SUSS MicroTec

service technician or person authorized by SUSS

MicroTec.

Users who open containers with system compo-

nents or install or transport the machine without a

SUSS MicroTec technician or a person authorized

by SUSS MicroTec do so at their own risk.

Power connections and supply connections (com-

pressed air, nitrogen, etc.) at the installation site

must be completely installed by the customer before

installation so the machine can be connected.

2.1. Prerequisites for Installa-

tion

The following installation prerequisites must be met

before the machine can be operated optimally:

2.1.1. Ambient Requirements

• The machine must be installed on a vibration-free

surface since vibrations can negatively influence

the machine’s function.

--> We recommend setting up the machine on a

SUSS MicroTec vibration-insulated base

frame intended for this purpose.

• The machine must be installed in a clean room.

Impurities in the air have negative effect on the

machine’s function.

--> We recommend clean room class 1000 or

better.

• The room temperature and relative humidity

should be controlled at the setup site.

--> We recommend a room temperature

between 20°C (68°F) and 22°C (72°F) and a

relative humidity between 45 and 55% (not

condensing).

• When planning the working area for the operator,

allow sufficient dorsal space. The microscope

moves forward for the exposure, therefore the

operator must have adequate space to back off

from the machine.

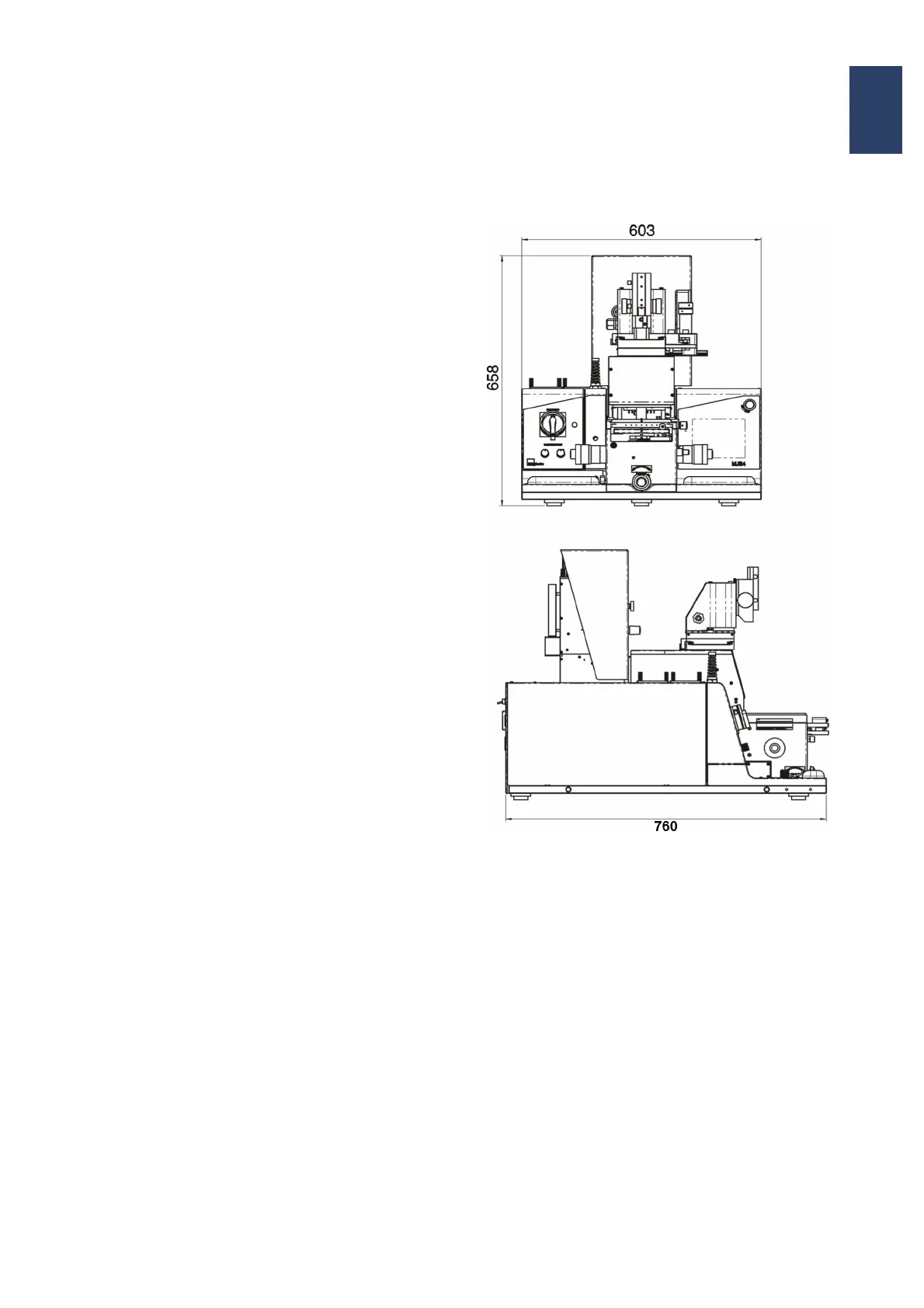

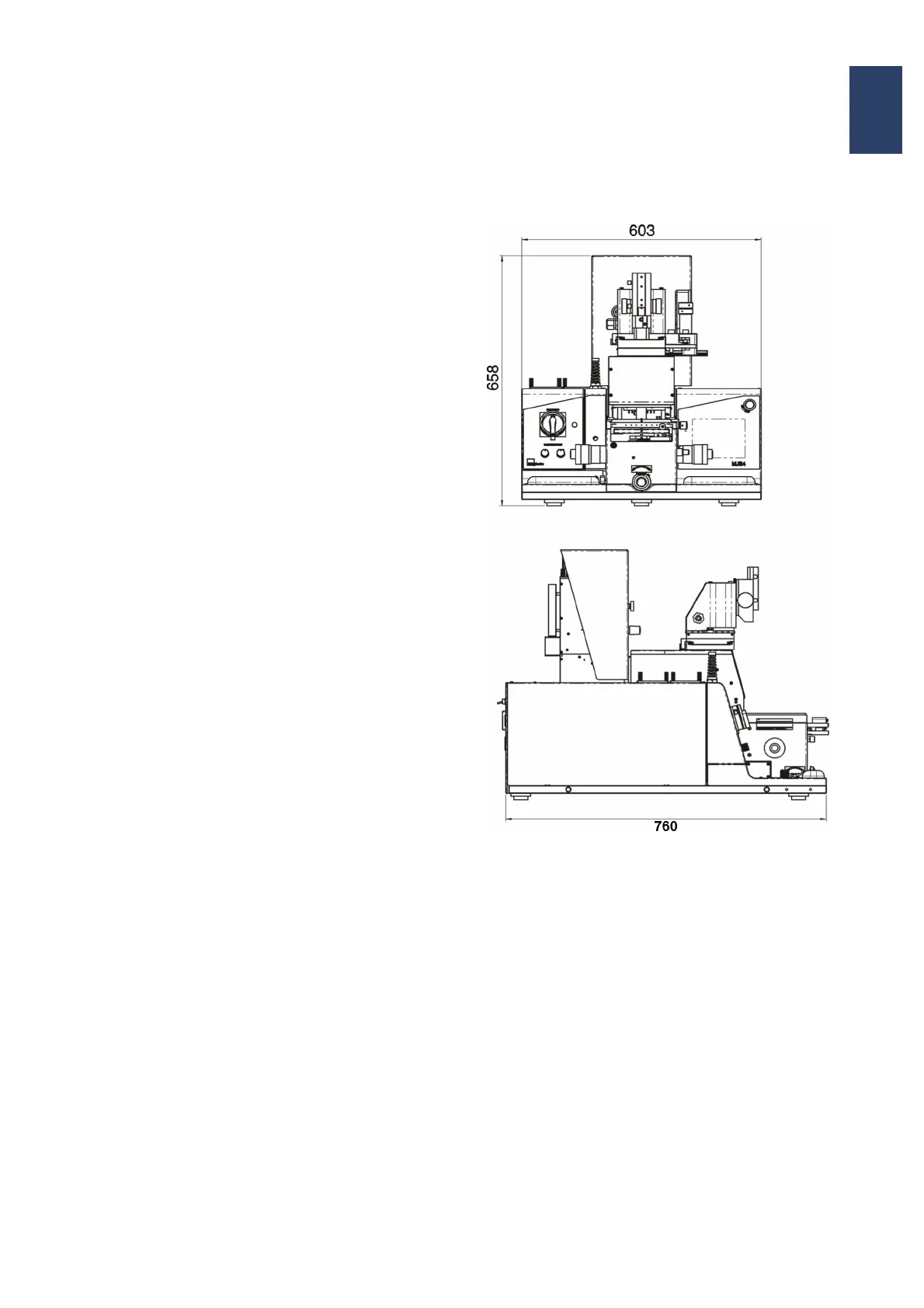

• The back of the machine must be at least 10 cm

(4 in) away from the room wall. See the figure

“Di-

mensions of the MJB4 Mask Aligner:” for the ex-

act dimensions of the aligner.

--> We recommend a distance of 30cm (12in).

Dimensions of the MJB4 Mask Aligner:

Width: 603 mm

Depth: 760 mm

Height: 658 mm

1400 mm (with base)

Weight: approx. 150 kg MJB4

160 kg base

Loading...

Loading...