OPERATION OF THE MJB4

28 MJB4 - Operation Rev07 05-10

3

3.4.5. Loading the Mask

Caution!

If the microscope is in the lower posi-

tion when loading or unloading the

mask, the microscope must be moved

to the upper position by pressing the

“Microscope is down” button. The but

-

ton changes to “Microscope is up” and

displays the actual position of the mi

-

croscope.

Mask Loading Routine

Remove the mask holder by loosening both knurled

screws on the mask holder frame and then place on

a tray upside down. Unload any mask if necessary

and insert the desired mask.

For safety reasons the „Mask vacuum is on“ button

must be pressed for 2 seconds to switch off the

mask vacuum.

The mask can be removed as soon as the button

changes to „Mask vacuum is off“.

Load the Mask

Place the mask on the mask holder against the stop

pins.

The button“ Mask vacuum is off“ is used to switch

on the mask vacuum.

Loading and Clamping the Mask Holder

With the top side facing up, push the mask holder

into the alignment station and then fasten it in the

mask holder frame using the knurled screws.

Attention!

Proper wedge error compensation is

not possible if the mask holder is not

clamped correctly in the alignment sta

-

tion. The exposure result will be insuffi-

cient!

3.4.6. Loading the Substrate

Pulling out the transport slide and loading the

substrate

Pull out the transport slide as far as it is possible.

Insert a suitable substrate chuck with the substrate

resting on the stop pins.

There is a hand valve on the front right side of the

transport slide that switches on the transport

vacuum for the contact and vacuum chuck.

Carefully insert the transport slide until it reaches the

end stop.

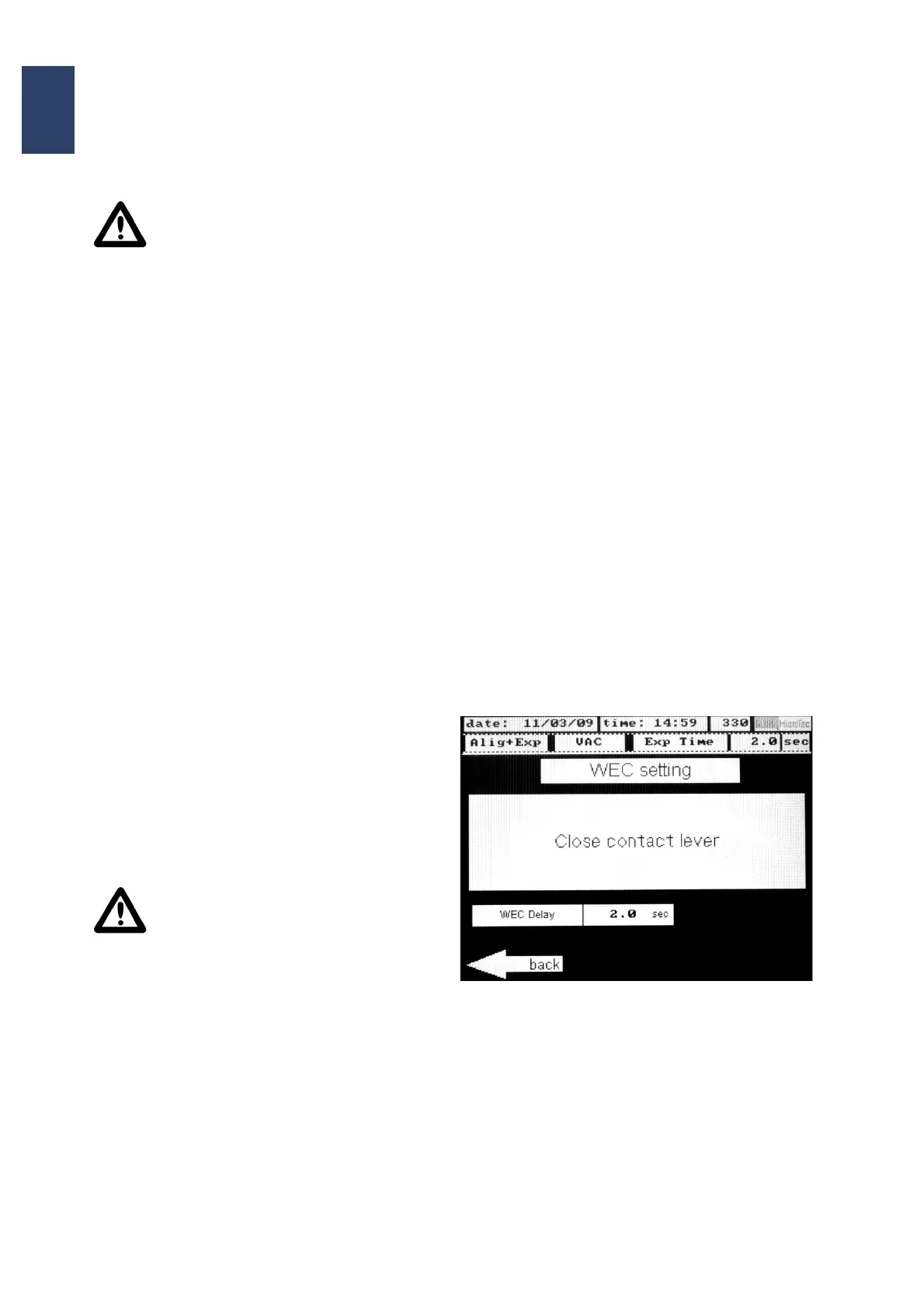

3.4.7. Setting the Mask Substrate

Thickness

For newly loaded equipment, the thickness setting at

the alignment station must be checked and reset if

necessary.

To do so, turn the thickness setting on the adjusting

table clockwise until it is at its lowest position. Now

load the new equipment with mask and substrate. In

the main menu select WEC settings.

• At the touch screen appears:

„Close contact lever“

Move the substrate towards the mask by pushing

the contact lever forwards. Afterwards turn the

thickness setting upwards (counterclockwise)

until the information „WEC setting OK“ appears

on the display.

Loading...

Loading...