OPERATION OF THE MJB4

20 MJB4 - Operation Rev07 05-10

3

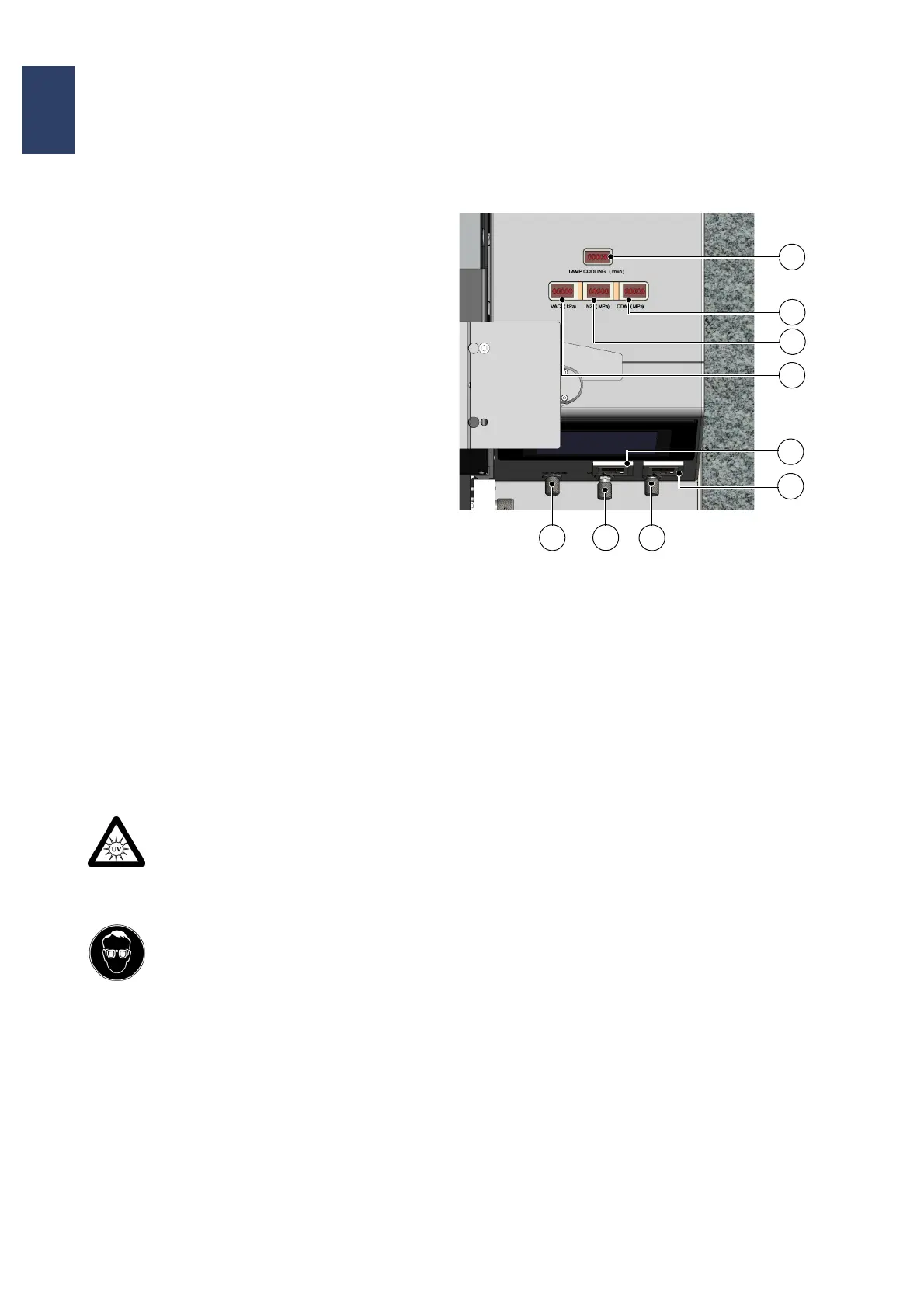

3.2.6. Lamp House

If the uniformity of the exposure lamp varies by more

than ±5%, it should be readjusted within the lamp

house and optics.

When an exposure lamp is replaced (see section

1.6.1.2. "Changing the Lamp"), the uniformity should

be checked first and then readjusted if necessary.

To do so, use the three setting knobs at the front of

the lamp house.

• Left setting knob for Y-direction

• Middle setting knob for Z-direction

• Right setting knob for X-direction

Setting Instructions:

The lamp must be on for about 20 minutes before it

reaches operating temperature. The Lamp test

function can be selected in the main menu. Using

the SUSS UV1000 intensity meter with the

appropriate probe, you check and set the intensity

and uniformity of the light.

Setting procedure: Place the probe in the center of

the light. The middle setting knob for the Z-direction

should be set so that the measuring device displays

the highest value. Do the same for the X- and Y-

directions.

Next, the light uniformity over the entire exposed

surface must be tested and, if necessary, slightly

corrected using the X, Y and Z setting knobs.

Attention!

UV light can seriously damage your

eyes.

Never remove the covers on the beam

path when the UV lamp is on!

Always wear UV protection goggles

and skin protection as well during lamp

adjustment.

UV protection goggles must be worn

even when measuring light on the

exposure chuck.

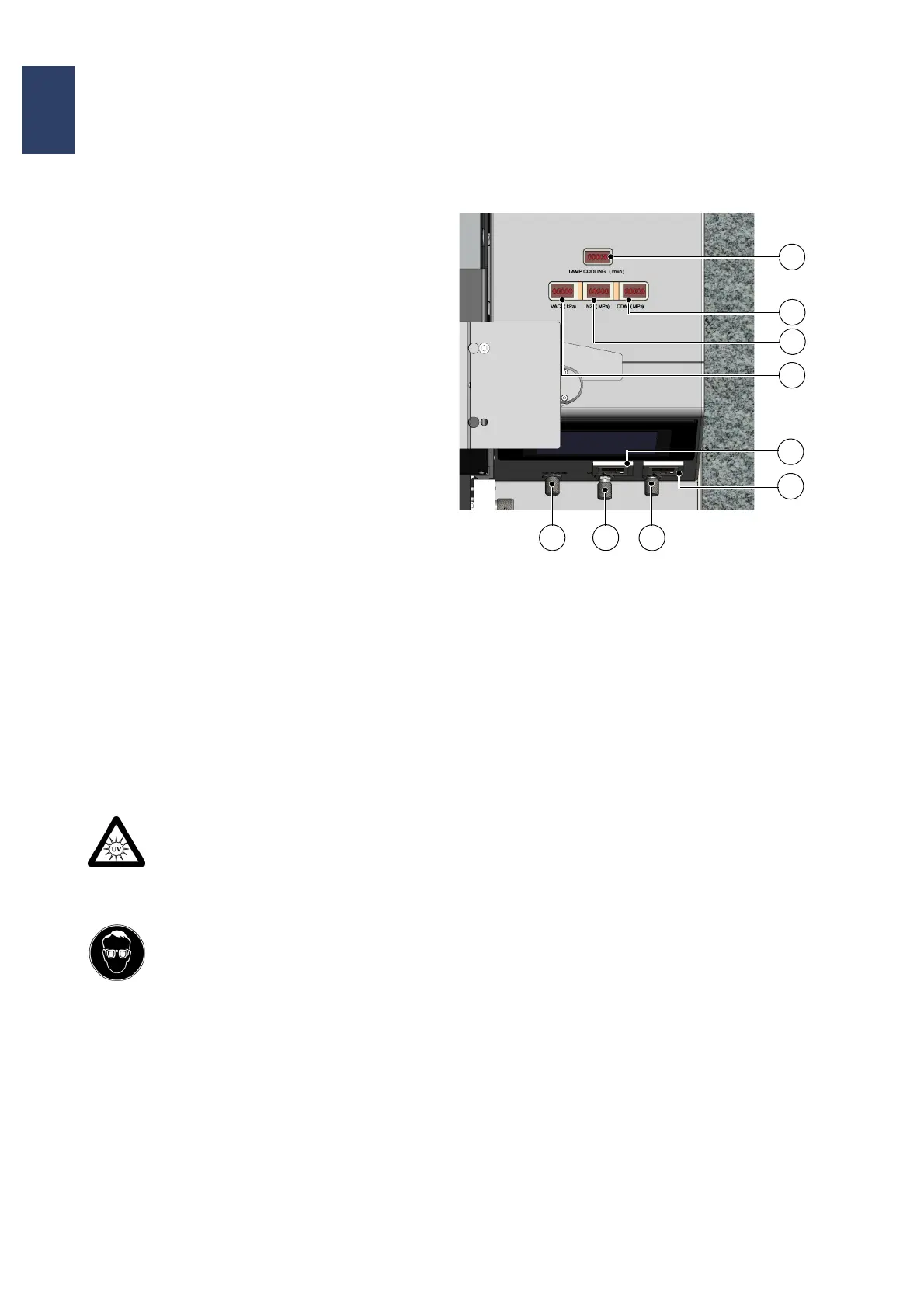

3.2.7. Basic Pneumatic Settings

Basic pneumatic settings

1 Nitrogen purge mask holder controller

2 Reduced vacuum chamber controller

3 WEC pressure controller

4 WEC pressure gauge

5 Vacuum chamber gauge

6 Vacuum gauge

7 Nitrogen gauge

8 CDA gauge

9 Lamp cooling gauge

Compressed Air

The device works reliably at an operating pressure

of >5.5 bar. The pressure must be set correctly on

the pressure reducing valve by a service engineer

and then read from the manometer.

Nitrogen

A nitrogen pressure rated at 1.5 bar must be set on

the pressure reducing valve by a service engineer

and then read from the manometer.

Nitrogen is used to cool the exposure lamp, to build

up additional pressure under the substrate (hard

contact exposure), as a cover gas for the substrate,

and to ventilate the vacuum chamber after vacuum

exposure.

1

2

3

9

8

7

6

5

4

Loading...

Loading...