AR 2000 Operator's Manual

55

Chapter 6

Measuring Systems

Overview

This chapter describes the geometries currently available from TA Instruments and provides guidelines to

choose the optimum geometry (or measuring system) for each application. A complete geometry catalog is

available which describes in detail each geometry and typical applications. Contact your local TA Instruments

office or their appointed agent for further details. Some theoretical considerations are given that will provide

guidance and help you maximize the use of the AR Rheometers.

TA Instruments offers a range of geometries. The geometries are divided into the following groups, each with a

range of sizes available:

• Cone and plate

• Parallel plate

• Concentric cylinders.

The following pages describe the types of geometries and provide details on how to attach the geometry to the

rheometer.

General Description

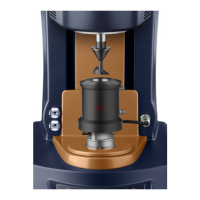

The measuring system is defined as those parts that are in direct contact with the sample or material.

A measuring system consists of two parts:

• One is the fixed member (or Stator), for example, the Peltier plate.

• The second part (the geometry) is attached to the driving motor spindle, where it is locked in position

using the draw rod. The draw rod is detachable and passes through the centre hole bored in the spindle.

The geometry constitutes the moving member of the system (the Rotor).

Geometry Materials

Geometries are usually constructed from stainless steel, aluminium, or acrylic (other materials can be supplied

upon request). The rotor should ideally be as light as possible to minimize inherent inertia effects. It should

also be chemically compatible with the test sample in order to avoid corrosion problems.

Stainless Steel

Stainless steel is relatively heavy, but it has a low coefficient of thermal expansion. It is compatible with most

test materials and is robust enough to withstand heavy use, even if you are a less experienced operator.

Aluminium

Aluminium has a higher thermal coefficient of expansion and is limited because of its chemical compatibility.

As it is lighter, inertial effects are not as great.

Loading...

Loading...