AR 2000 Operator's Manual

56

Plastic

Engineering grade acrylic, polycarbonate, and rigid PVC are all suitable materials for geometry construction.

These are transparent so the visual behavior of the sample can be observed. Plastic geometries are also much

lighter than metallic geometries.

Acrylic and polycarbonate have less inertial problems as they are relatively light, but they have limited

chemical compatibility. You should not use plastic geometries above 40°C.

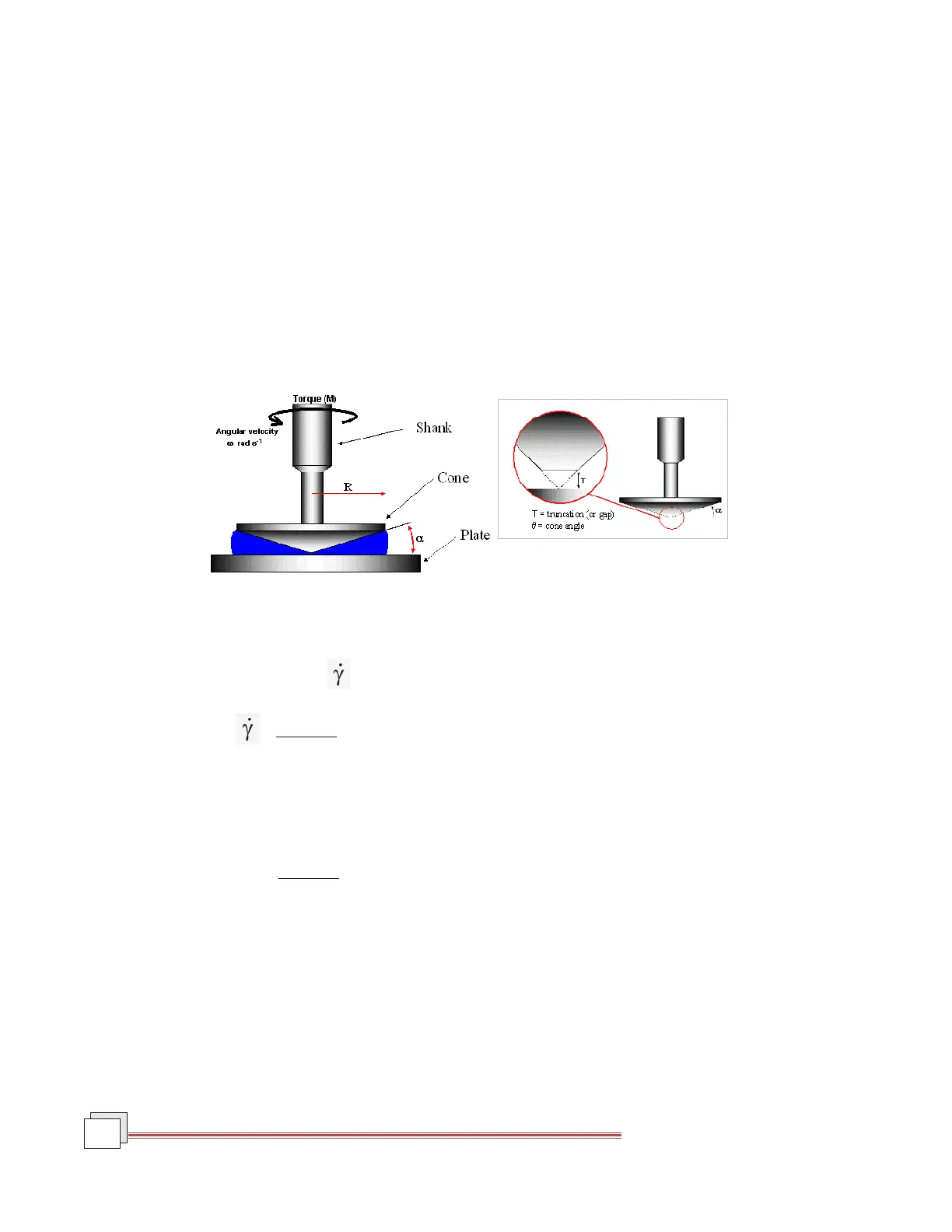

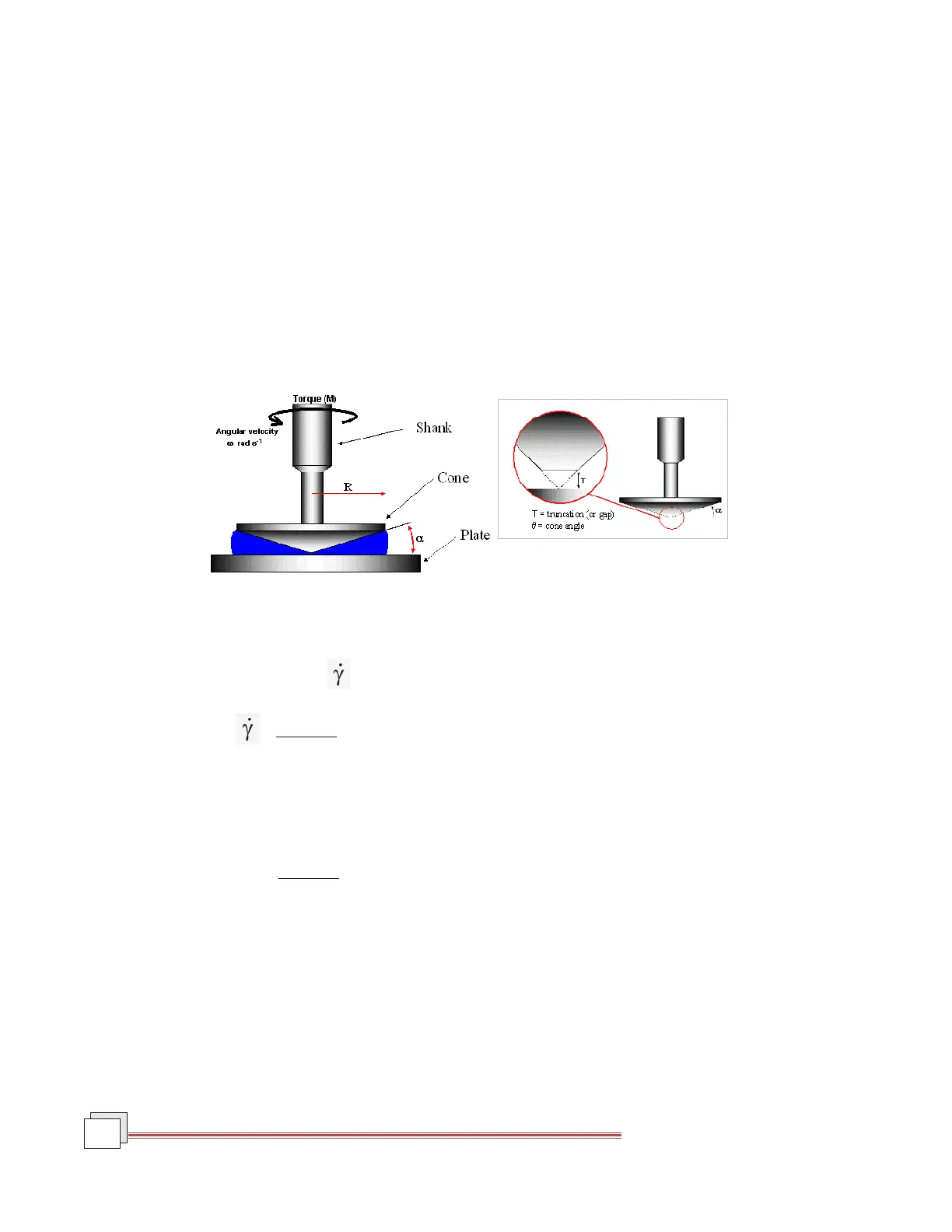

Cone and Plate

A schematic of a cone and plate system is shown below in Figure 6.1. It is important to know how to calculate

the stress and shear rate factors for each geometry before deciding on the geometry dimensions.

Figure 6.1

The Cone and Plate

Shear rate (s

-1

) = F

ω

where F = 1

tan

α

Shear stress (Pa) = F

σ

M

where F

σ

= 3

2

π

R

3

The standard diameters available are 20 mm, 40 mm and 60 mm with cone angles of 0.5° to 4° in 0.5° incre-

ments.

Cone and plate geometries are generally used for single-phase homogeneous samples or samples with submi-

cron particles. Samples containing particulate matter are usually unsuitable for cone and plate geometries as

the particles will tend to migrate to the apex of the cone and will get jammed in the truncation area. Erroneous

data will result.

Loading...

Loading...