AR 2000 Operator's Manual

57

The angles and truncation values of each cone are individually calibrated. A calibration certificate is available.

The serial number, angle and truncation are all inscribed on the stem of each cone.

Parallel Plate

The parallel plate system allows samples containing particles to be effectively measured. You can set the gap to

any distance, thereby eliminating the problems due to particles size. A good rule of thumb for particulate

materials is to set a gap size set at least 10 times greater than the largest particle size. For example, if the maxi-

mum particle size is 100 mm, you should set the gap to at 1000 mm.

The main disadvantage of a parallel plate system is that the stress is not uniform across the entire diameter.

However, the software compensates for this fact. The shear stress and shear rate factors given are with respect

to the rim.

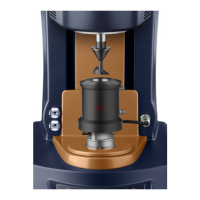

A schematic of a parallel plate is shown in Figure 6.2.

Figure 6.2

The Parallel Plate

Loading...

Loading...