AR 2000 Operator's Manual

62

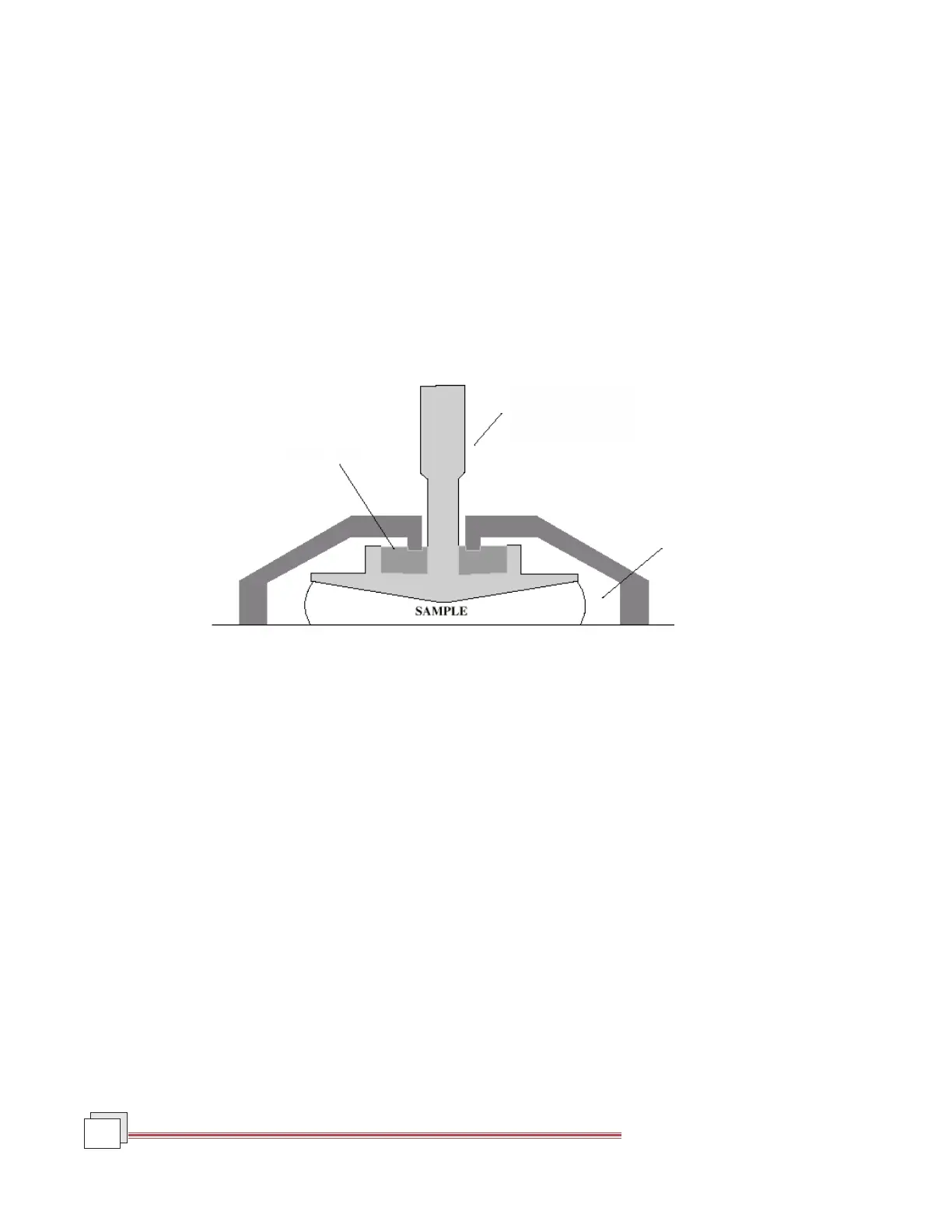

Preventing Solvent Evaporation

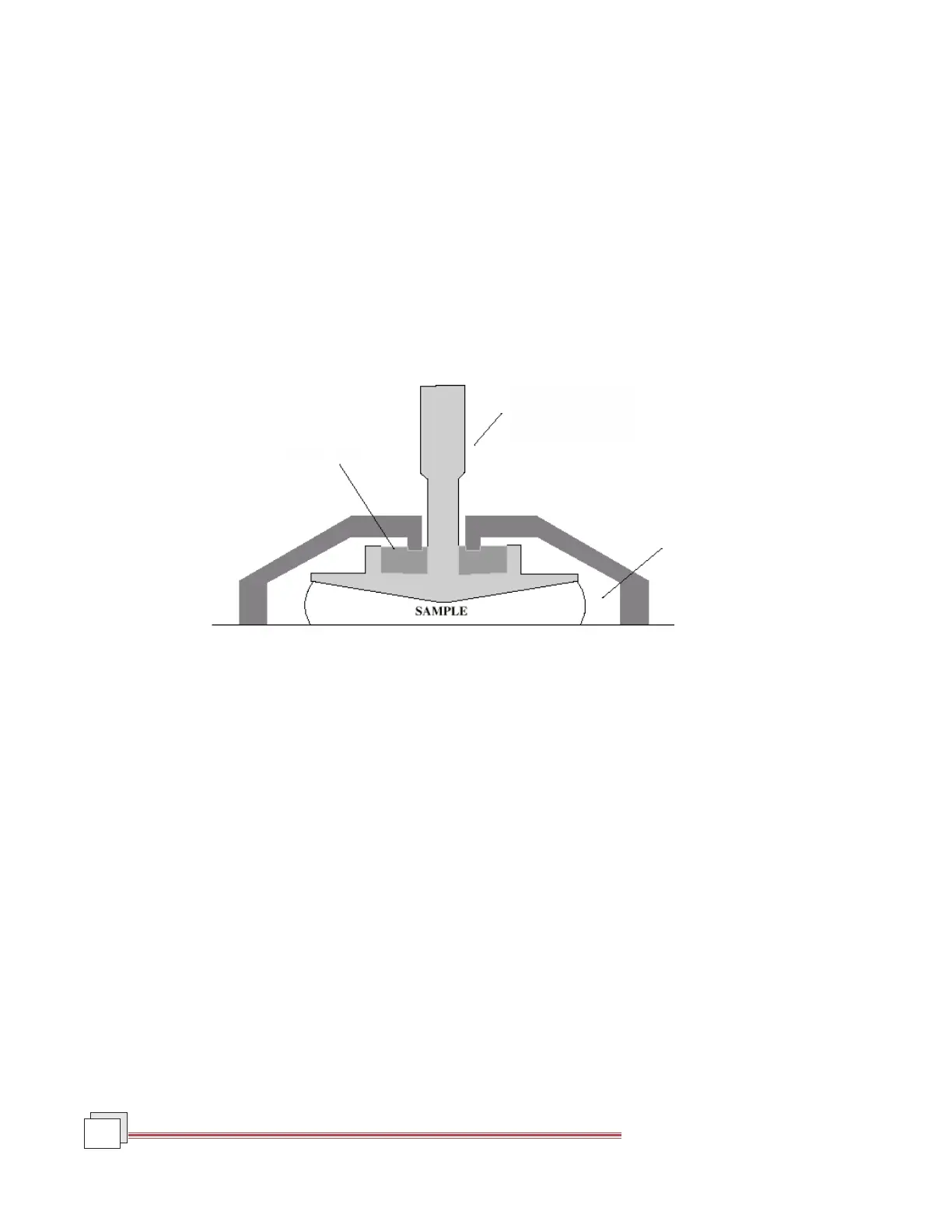

If you are using samples that contain volatile solvents or are water-based, evaporation can cause problems

during measurements. TA Instruments has overcome this problem by using a solvent trap cover, which sits over

the geometry (but does not touch it).

Solvent trap version geometries have a well on top of the geometry. Place a small amount of the relevant solvent

into this well. The solvent trap cover has a lip that sits in the solvent, allowing the free space around the sample

to become saturated with the solvent vapor, which prevents evaporation.

A schematic of a solvent trap cover and geometry is shown in Figure 6.7 below.

When using solvent trap systems it is generally advisable to run the inertia correction wizard (with solvent in

the trap, but no sample loaded).

Preventing Slippage at

Sample/Geometry Interface

Some samples, such as hydrogels, contain a lot of water that can migrate to the surface of the sample. This can

cause a film layer to form between the bulk of the material and the geometry surface, causing slippage at this

interface. To alleviate this problem, use special crosshatched geometries, which, in effect, have the measuring

surface slightly roughened. (However, when you use these crosshatched geometries, there is a trade-off between

absolute accuracy and repeatability.)

Solvent well

Solvent trap

version

geometry

Solvent

vapor

saturated

free space

Figure 6.7

Solvent Trap Cover and Geometry

Loading...

Loading...