Adjustment

Procedure-2445A/2455A

Service

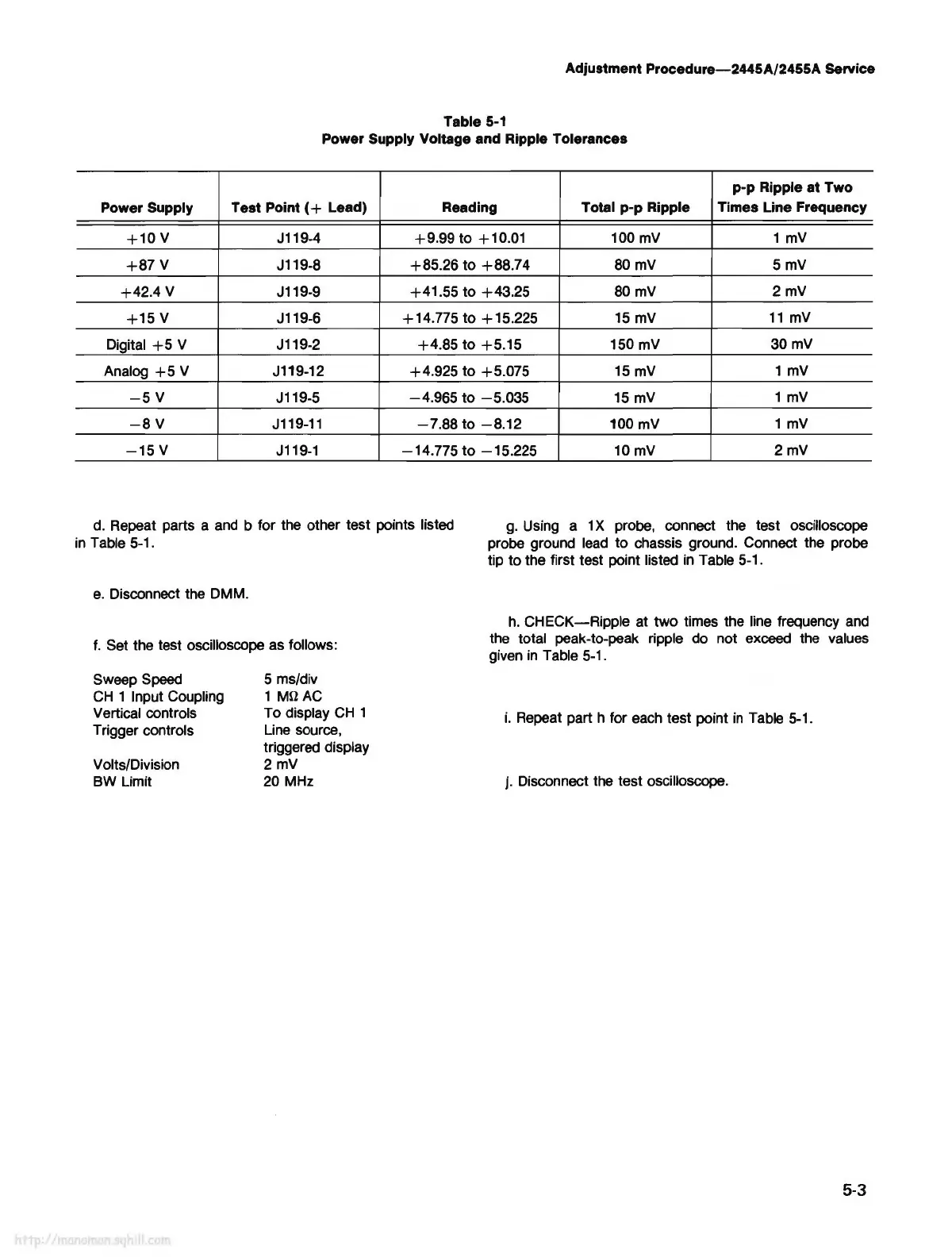

Table

5-1

Power Supply Voltage and Ripple Tolerances

p-p Ripple at Two

Power Supply Test Point (

+ Lead) Reading

Total p-p Ripple Times Line Frequency

+10v

J119-4

+9.99

to

+

10.01

100

mV

1

mV

+87V

J119-8

+85.26

to

+88.74

80

mV

5mV

+42.4

V

J119-9

+41.55

to

+43.25

80

mV

2mV

+15

V

J119-6 +14.775

to

+15.225

15

mV

11

mV

Digital

+5

V

J119-2

+4.85

to

+5.15

150 mV

30mV

Analog

+5

V

J119-12

+4.925

to

+5.075

15

mV

1

mV

-5V

J119-5

-4.965

to

-5.035

15

mV

1

mV

-8V

J119-11

-7.88

to

-8.12

100 mV

1

mV

-15

V J119-1

-14.775

to

-15.225

10

mV

2mV

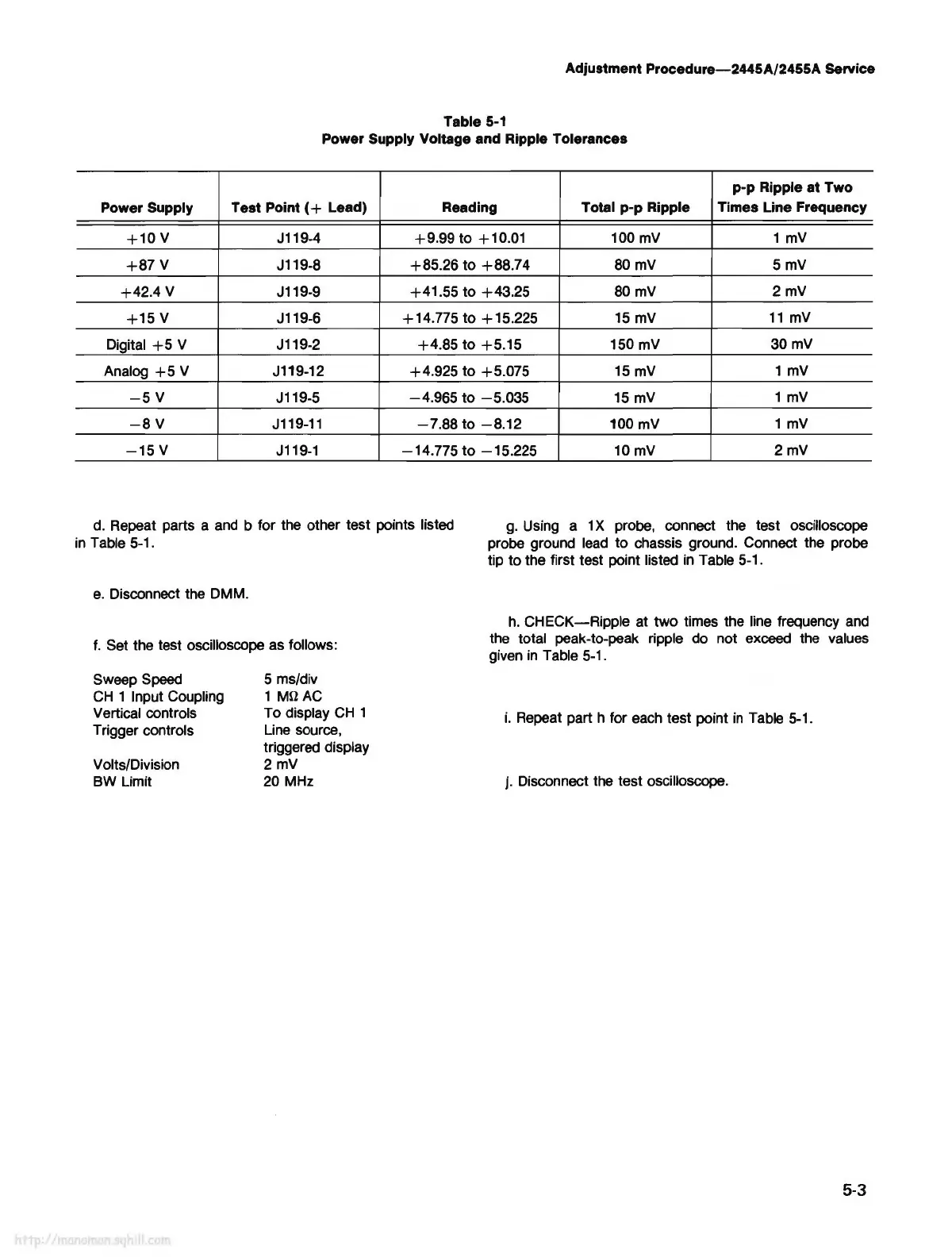

d. Repeat parts a

and

b for the other test points listed

in

Table 5-1.

g.

Using a 1 X probe, connect the test oscilloscope

probe ground

lead

to

chassis ground. Connect the probe

tip

to

the first test point listed

in

Table 5-1.

e.

Disconnect the DMM.

f.

Set the test oscilloscope as follows:

Sweep Speed

CH

1 Input Coupling

Vertical controls

Trigger controls

Volts/Division

BW Limit

5 ms/div

1 Mil

AC

To display

CH

1

Line source,

triggered display

2mV

20 MHz

h.

CHECK-Ripple

at

two

times the line frequency

and

the total peak-to-peak ripple do not exceed the values

given

in

Table 5-1.

i.

Repeat part h for each test point

in

Table 5-1.

j. Disconnect the test oscilloscope.

5-3

Loading...

Loading...