- 6 -

- Only use electrodes that are recommended for the machine (see spare parts

list) without altering their shape.

- RISK OF BURNING

Someofthespotwelderparts(electrodes-armsandadjacentareas)can

reach temperatures of above 65°C: suitable protective clothing must be

worn.

Allownewly-weldedpiecestocoolbeforetouchingthem!

- RISK OF TOPPLING AND FALLS

- Place the spot welder on a horizontal surface that can suitably support the

mass; constrain the spot welder to the supporting surface (when indicated

inthe“INSTALLATION”sectionofthismanual).Incontrarycases,where

theooringisslopedorbroken,orwithmobilesupportingsurfaces,the

danger of toppling exists.

- It is forbidden to lift the spot welder, excluding where expressly indicated in

the“INSTALLATION”sectionofthismanual.

- When using machines on wheels: disconnect the spot welder from the

electric and pneumatic (if present) power supplies before moving the unit

to another work area. Pay attention to obstacles and unevenness on the

ground (for example cables and piping).

- UNINTENDED USE

It is dangerous to use the spot welder for any purpose other than that for

which it is intended (see INTENDED USE).

SAFEGUARDS AND SHIELDS

The safeguards and mobile parts of the spot welder casing must be in position,

before connecting it to the power supply.

WARNING!Anymanualinterventionontheaccessiblemobilepartsofthespot

welder,forexample:

- Replacement of or maintenance on the electrodes

- Adjustmentofthearmorelectrodepositions

MUST BE CARRIED OUT WITH THE SPOT WELDER SWITCHED OFF AND

DISCONNECTEDFROMTHEELECTRICANDPNEUMATIC(ifpresent)POWER

SUPPLY.

MAINSWITCHLOCKEDAT“O”WITHLOCKCLOSEDANDKEYREMOVEDinthe

modelswithPNEUMATICCYLINDERmovement).

STORAGE

- Place the machine and its accessories (with or without packaging) in closed

areas.

- Therelativehumidityoftheairmustnotexceed80%.

- The environmental temperature must be between -15°C and 45°C.

If the machine has a water cooling unit and the environmental temperature is

lower than 0°C: add the indicated antifreeze liquid or completely empty the

hydraulic circuit and the water tank.

Always use suitable measures for protecting the machine from humidity, dirt

and corrosion.

2. INTRODUCTION AND GENERAL DESCRIPTION

2.1 MAIN CHARACTERISTICS

Column spot welding machine with electrode and curved descent for resistance

weldingsystem(singlespot)withdigitalmicroprocessorcontrol.

Their main characteristics are:

- limitationoflineovercurrentatinsertion(insertioncosφcheck);

- choiceofthebestspotweldingcurrentaccordingtothemainspoweravailable;

- choice of the optimal welding cycles parameters (approach time, ramp time,

weldingtime,pausetimeandpulsenumber);

- savingoffavouriteprogrammes;

- backlitLCDdisplaythatshowsthecontrolsandthesetparameters;

- thermalprotectionwithindicator(overloadorlackofcoolingwater);

- indicatingandblockingintheeventofoverloadorunderloadofdeliveredvoltage;

- noairindicator(onlyonPCPpneumaticcontrolmodels);

- airowregulationforslowarmclosing(onlyonPCPpneumaticcontrolmodels).

Operation:

- ”PTE”models:mechanical,equippedwithpedalwithadjustableleverlength;

- ”PCP”models:pneumatic,equippedwithdoubleeffectcylindercontrolledbya

pedal valve.

2.2 OPTIONAL ACCESSORIES

- Armpair,length500mm,completewithelectrodeholdersandstandardelectrodes.

- Armpair,length700mm,completewithelectrodeholdersandstandardelectrodes.

- Curvedelectrodes.

- Closedcircuitwatercoolingsystem(suitableforPTEorPCP18only).

3. TECHNICAL DATA

3.1 RATING PLATE (FIG. A)

Themaindatarelatingtouseandperformanceofthespot-welderaresummarisedon

the rating plate and have the following meanings:

1- Numberofphasesandfrequencyofpowersupply.

2- Powersupplyvoltage.

3- Mainspowerwithpermanentrunning(100%).

4- Ratedmainspowerwith50%dutycyde.

5- Maximumloadlessvoltageoverelectrodes.

6- Maximumcurrentwhenelectrodesareshorted.

7- Currenttosecondarywhenrunningpermanently(100%).

8- Gaugeandlengthofarms(standard).

9- Minimumandmaximumadjustableelectrodeforce.

10- Ratedpressureofcompressedairsupply.

11- Pressureofcompressedairsupplyneededtoobtainmaximumelectrodeforce.

12- Coolingwaterowrate.

13- Ratedpressuredropforcoolantliquid.

14- Weight of welding device.

15- Safetysymbols,themeaningsofwhicharegiveninchapter1“Generalsafety

rulesforresistancewelding”.

Note:Theratingplateshownisanexampletoshowthemeaningofthesymbolsand

numbers;theexacttechnicalspecicationsofyourspot-weldercanbefoundonthe

rating plate of the spot-welder itself.

3.2 OTHER TECHNICAL DATA (FIG. B)

4.DESCRIPTIONOFTHESPOT-WELDER

4.1SPOT-WELDERASSEMBLYANDDIMENSIONS(FIG.C)

4.2 CONTROL AND ADJUSTMENT DEVICES

4.2.1 Control panel (FIG. D1).

1- main switch (inPCPmodels withemergencystop functionand lockfunctionin

position“O”:lockandkeysupplied).

2- increase(+)decrease(-)buttons.

3- “MODE”settingsselectorbutton.

4- rear-litLCDdisplay;

5- run/STARTbutton(mod.PCP);

6-

/ pressureonlyswitch(nowelding)/welding.

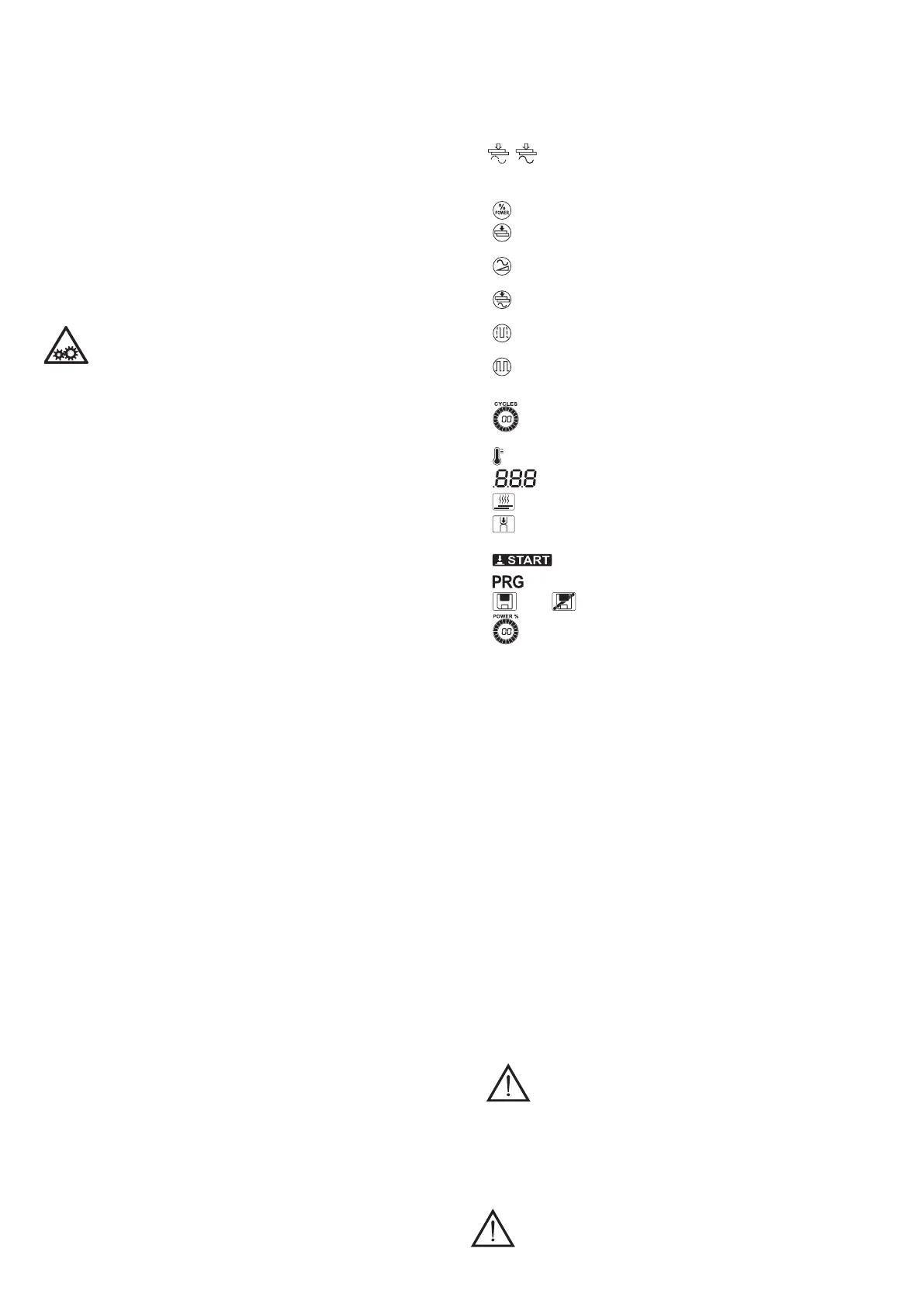

4.2.2 Description of the icons (FIG. D2).

Spot welding parameters (1-7):

1-

power(%):spotweldingcurrentasapercentageofthemaximumvalue;

2-

approach(cycles):stand-bytimesincyclesbeforedeliveringcurrentfromthe

contactoftheelectrodeswiththepiecebeingprocessed;

3-

ramp(cycles):timeincyclesthatthespotweldingcurrenttakestoreachthe

valuesetfor“power”;

4-

spotweldingtime(cycles):timeincyclesthatthecurrentremainsattheset

value;

5-

pausetime(cycles):timeincyclesduringwhichthecurrentiszerobetween

onepulseandanother(onlyinpulsemode);

6-

pulsenumber(n°):if1thenthespotweldingstopsafterspotweldingtime(4);

if greater than 1, it indicates the number of current pulses delivered by the

machine(pulsemode);

7-

circular synoptic indicator, with numerical value inthe centre, of the set

cycles;

8-

thermalalarmicon;

9-

multifunctionnumericaldisplay;

10-

spotweldingenabledicon(deliveryofcurrent);

11-

approach enabled icon, with selector switch in FIG. D1-6 in the NO

WELDINGposition;

12-

STARTindicator:pressthebuttoninFIG.D1-5tostartthemachine;

13-

customisedPROGRAMMEicon;

14-

save / donotsavecustomisedprogrammeicon;

15-

circular synoptic indicator, with numerical value inthe centre, of the set

power.

4.2.3 Setting of the spot welding parameters

Eachtimethemachineisswitchedon,andbeforepressingthe“START”button,itis

possibletochangethefunctionmodeusedtosettheweldingparameters:

- “REDUCED”=EASYmode: allowsquickand user-friendlyselectingof the two

mainspotweldingparameters“POWER”(1)and“weldingtime”(4).Thisfunction

modedoesnotforeseethesavingofcustomisedprogrammes.

- “EXTENDED” = EXPERT mode: allows the selecting of all the welding parameters

described in the paragraph above. This function mode allows the saving of

customisedprogrammes.

4.2.4Compressionandowregulatornut(FIG.D3)

1- The nut can be accessed via the hatch door on the rear of the spot welding

machine.

Thenutisusedtoregulatetheforceexertedbytheelectrodesinterveningonthe

springpreload:thegreaterthespringload,thegreatertheforceofthespotwelding

machine electrodes.

2- Theowregulator(PCPmod.only)isusedtodecreasethearmclosurespeedto

preventtheelectrodesfromreboundingonthepiece.

Rotatetheadjusterscrewcounterclockwise(+)toincreaseairowanddescent

speedoftheelectrodes;rotatethescrewclockwise(-)todecreaseairowandthe

descent speed of the electrodes.

4.2.5 Pressure and pressure gauge regulation (FIG. D4 - PCP mod. only)

1- Pressureregulatorknob;

2- Pressuregauge.

4.2.6 Air and water couplings (FIG. G and H)

G(1)-Compressedairpipecoupling(PCPmod.only);

G(2)-Condensatelterandbleeder(PCPmod.only);

H(1)-INLETwatercouplings.

H(2)-OUTLETwatercouplings.

4.3SAFETYFUNCTIONSANDINTERLOCK

4.3.1 Main switch

- Position“O”=openandlockable(seechapter1).

ATTENTION! The internal power cable connection terminals

(L1+L2)arelivewhenturnedtothe“O”position.

- Position“I”=closed:spotweldingmachinepoweredupbutnotoperating(STAND

BY)displayON.

Emergency function

Opening the spot welding machine when it is operating (position “I” => position “O”) will

instantlystopthemachineinsafeshutdownmodewith:

- currentinhibited;

- allmovementisblocked:exhaustercylinder(ifinstalled);

- automaticrestartinhibited.

ATTENTION! PERIODICALLY MAKE SURE THE SAFE SHUTDOWN

FUNCTIONOPERATESCORRECTLY.

Loading...

Loading...