SERVICE AND ADJUSTMENTS

6 - 5

Issued: August 2003RT700 Series

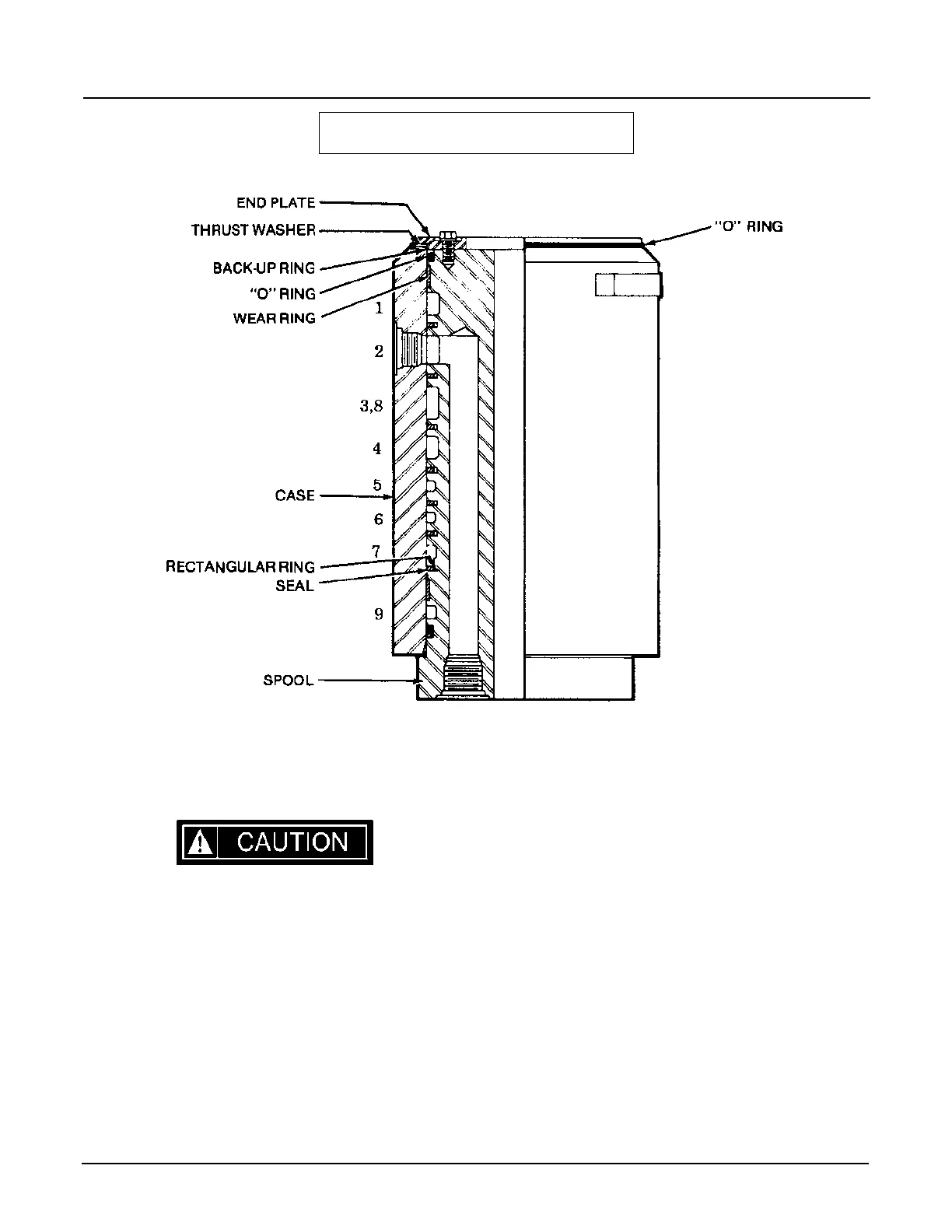

ROTARY MANIFOLD

Use the following procedures when disassembling, inspect-

ing, repairing, and reassembling the rotary manifold.

DISASSEMBLY

The rotary manifold may be disassembled by removing the

four capscrews and the top plate.

NOTE: Be sure to mark an index point on the case and

spool to insure proper reassembly.

INSPECTION AND SEAL REPLACEMENT

1. The “case” bore should be thoroughly washed with sol-

vent or diesel fuel and inspected for signs of “scoring”

or deep scratches. This type of damage is generally

caused by the presence of foreign material in the

hydraulic system. No satisfactory method of repairing

this type of damage can be conducted in the field.

AS SOON AS THE ROTARY MANIFOLD IS READY TO

BE PLACED INTO OPERATION, IT SHOULD BE

SLOWLY ROTATED SEVERAL MINUTES TO ALLOW

ANY ENTRAPPED AIR TO ESCAPE AND TO FACILI-

TATE REFORMING OF SEALS THAT MAY HAVE

TEMPORARILY DEFORMED DURING STORAGE.

All overhaul should be done in a clean, enclosed facility with

personnel familiar with hydraulic systems and cleanliness

procedures.

Loading...

Loading...