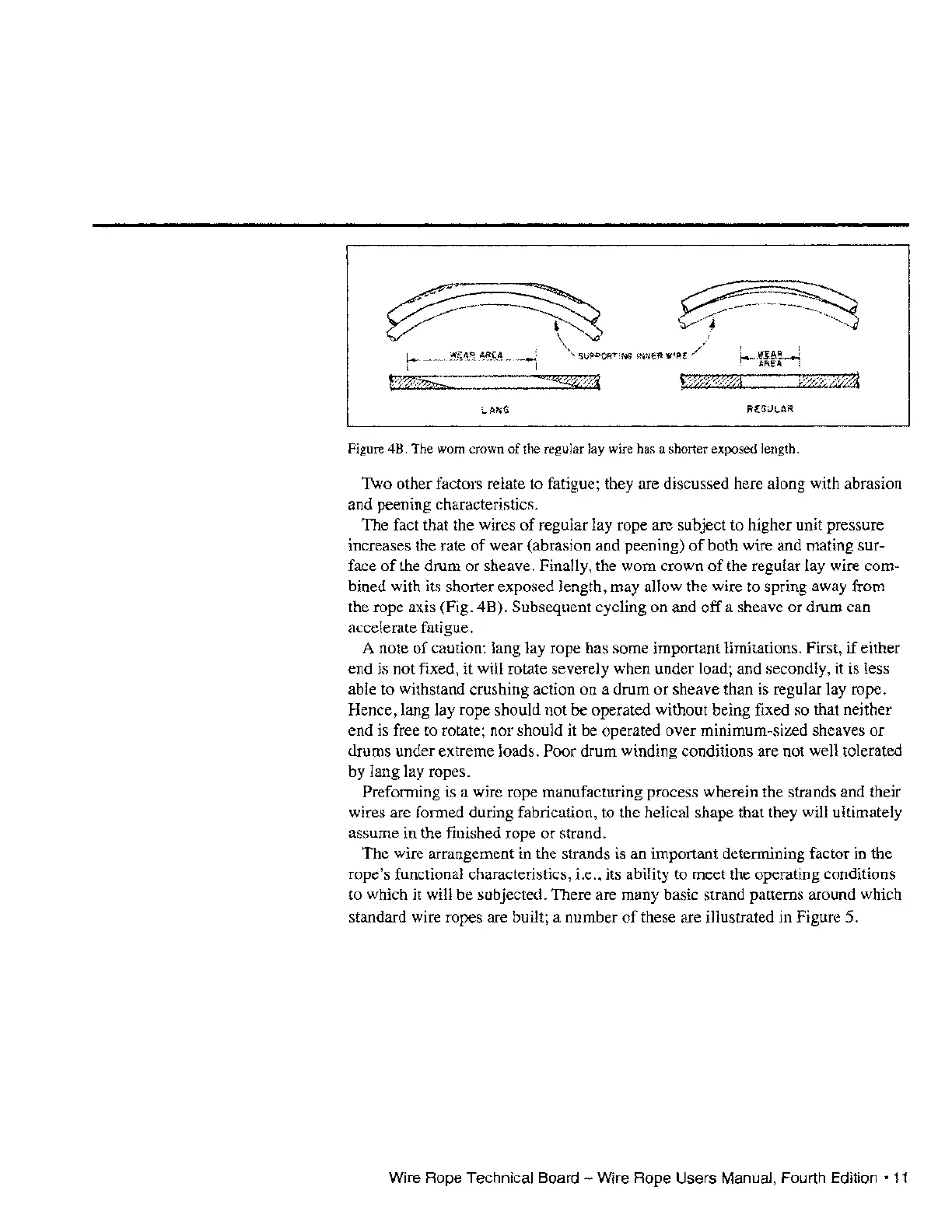

Figure 4B. The worn crown

of

the regular lay wire has a shorter exposed length.

Two other factors relate to fatigue; they are discussed here along with abrasion

and peening characteristics.

The fact that the wires

of

regular lay rope are subject to higher unit pressure

increases the rate

of

wear (abrasion and peening)

of

both wire and mating sur-

face

of

the drum or sheave. Finally, the worn crown

of

the regular lay wire com-

bined with its shorter exposed length, may allow the wire to spring away from

the rope axis (Fig. 4B). Subsequent cycling on and off a sheave or drum can

accelerate fatigue.

A note

of

caution: lang lay rope has some important limitations. First,

if

either

end is not fixed, it will rotate severely when under load; and secondly, it is less

able to withstand crushing action on a drum or sheave than is regular lay rope.

Hence, lang lay rope should not be operated without being fixed so that neither

end is free to rotate; nor should it be operated over minimum-sized sheaves

or

drums under extreme loads. Poor drum winding conditions are not well tolerated

by lang lay ropes.

Preforming is a wire rope manufacturing process wherein the strands and their

wires are formed during fabrication, to the helical shape that they will ultimately

assume in the finished rope or strand.

The wire arrangement in the strands is an important determining factor in the

rope's functional characteristics, i.e., its ability to meet the operating conditions

to which

it

will be subjected. There are many basic strand patterns around which

standard wire ropes are built; a number

of

these are illustrated in Figure 5.

Wire Rope Technical Board - Wire Rope Users Manual, Fourth Edition ·11

Loading...

Loading...