Unwinding wire rope from its reel also requires careful and proper procedure.

There are three methods to perform this step correctly:

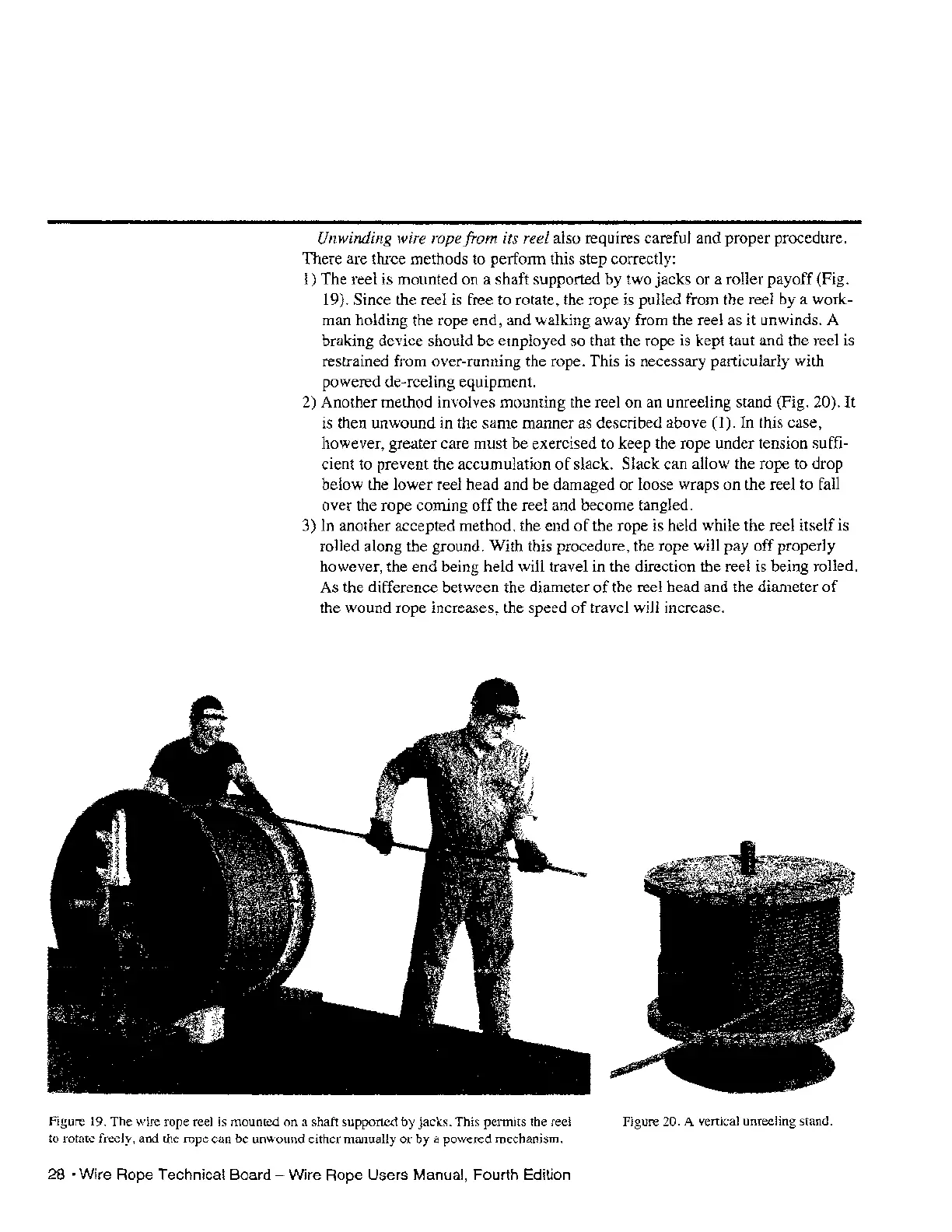

1)

The reel is mounted on a shaft supported by two jacks or a roller payoff (Fig.

19). Since the reel is free to rotate, the rope is pulled from the reel by a work-

man holding the rope end, and walking away from the reel as it unwinds. A

braking device should be employed so that the rope is kept taut and the reel is

restrained from over-running the rope. This is necessary particularly with

powered de-reeling equipment.

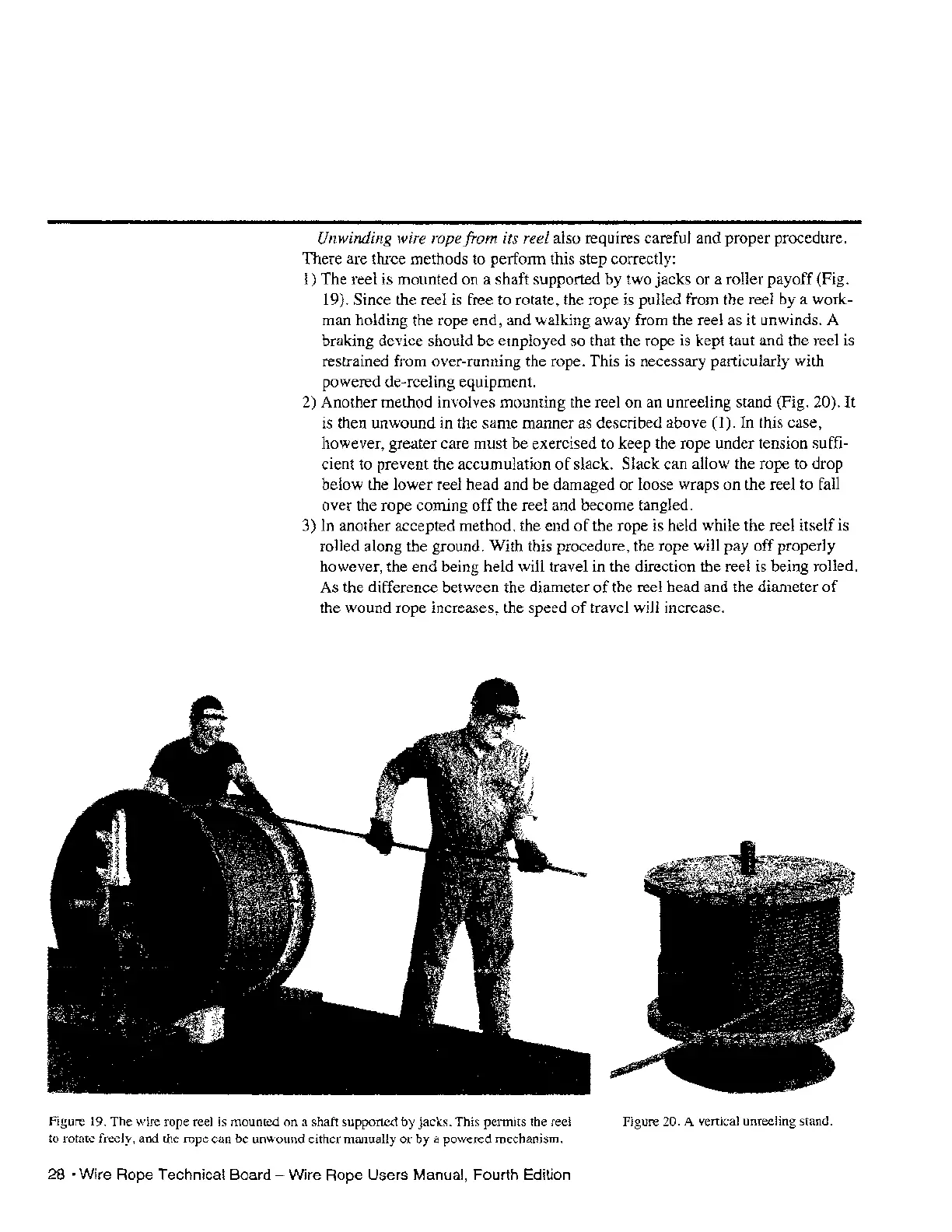

2) Another method involves mounting the reel on an unreeling stand (Fig.

20).

It

is then unwound in the same manner as described above (1). In this case,

however, greater care must be exercised to keep the rope under tension suffi-

cient to prevent the accumulation

of

slack. Slack can allow the rope to drop

below the lower reel head and be damaged or loose wraps on the reel to fall

over the rope coming off the reel and become tangled.

3) In another accepted method, the end

of

the rope

is

held while the reel itself is

rolled along the ground. With this procedure, the rope will

payoff

properly

however, the end being held will travel in the direction the reel is being rolled.

As the difference between the diameter

of

the reel head and the diameter

of

the wound rope increases, the speed

of

travel will increase.

Figure 19. The wire rope reel

is

mounted

on

a shaft supported by jacks. This pennits the reel

to rotate freely, and the rope can be unwound either manually

or

by

a powered mechanism.

28 • Wire Rope Technical Board - Wire Rope Users Manual, Fourth Edition

Figure 20. A vertical unreeling stand.

Loading...

Loading...