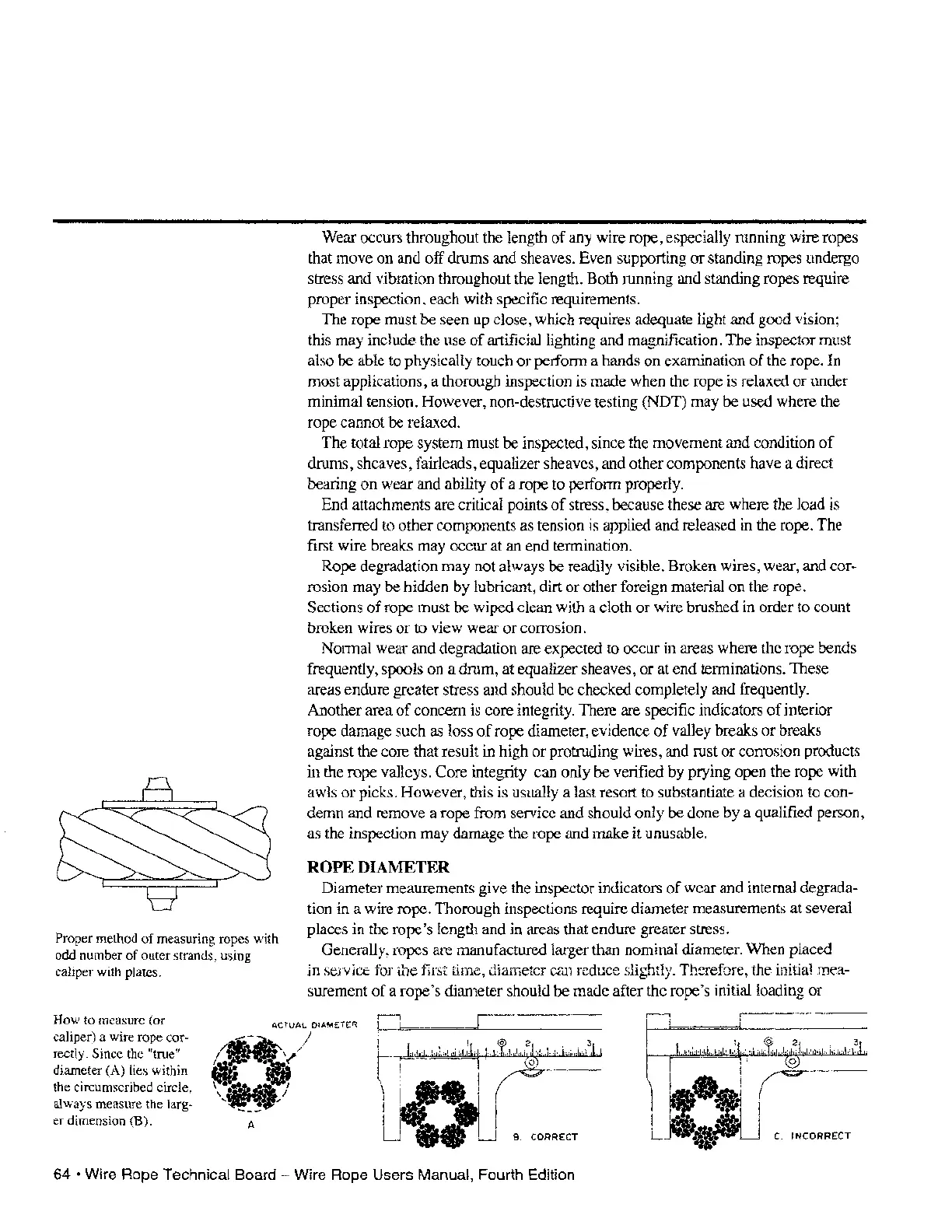

Proper method

of

measuring ropes with

odd number

of

outer strands, using

caliper with plates.

Wear

occurs throughout

the

length of

any

wire

rope, especially running

wire

ropes

that move

on

and off

churns

and

sheaves. Even supporting or standing

ropes

undergo

stress

and vibration throughout

the

length. Both running

and

standing

ropes

require

proper inspection, each

with

specific requirements.

The

rope

must

be

seen

up

close,

which

requires adequate light and good vision;

this

may

include

the

use

of artificial lighting

and

magnification. The inspector must

also

be

able

to

physically touch or perform a hands on examination of

the

rope.

In

most applications, a thorough inspection

is

made

when

the

rope

is

relaxed or under

minimal tension. However, non-destructive testing

(NDT)

may

be

used

where

the

rope cannot

be

relaxed.

The

total rope system must be inspected,

since

the

movement and condition of

drums, sheaves, fairleads, equalizer sheaves, and other components

have

a direct

bearing on wear and ability of a rope

to

perform properly.

End attachments are critical points of stress, because

these

are

where

the

load

is

transferred

to

other components

as

tension

is

applied

and

released

in

the

rope.

The

first

wire

breaks

may

occur

at

an

end termination.

Rope degradation

may

not

always

be

readily visible. Broken wires,

wear,

and

cor-

rosion

may

be

hidden by lubricant, dirt or other foreign material on

the

rope.

Sections of

rope

must

be

wiped clean

with

a cloth or

wire

brushed

in

order

to

count

broken

wires

or

to

view

wear or corrosion.

NOlmal

wear

and

degradation

are

expected

to

occur

in

areas

where

the

rope

bends

frequently, spools

on

a drum,

at

equalizer sheaves, or

at

end terminations. These

areas

endure greater stress

and

should

be

checked completely

and

frequently.

Another area of concern

is

core integrity. There

are

specific indicators of interior

rope

damage such

as

loss

of

rope diameter, evidence of

valley

breaks or

breaks

against

the

core that result

in

high or protruding wires,

and

rust or corrosion products

in

the

rope valleys. Core integrity

can

only

be verified

by

prying open

the

rope

with

awls

or picks. However,

this

is

usually a

last

resort

to

substantiate a decision

to

con-

demn

and

remove a rope from service and should only

be

done

by

a qualified person,

as

the

inspection

may

damage

the

rope

and

make it unusable.

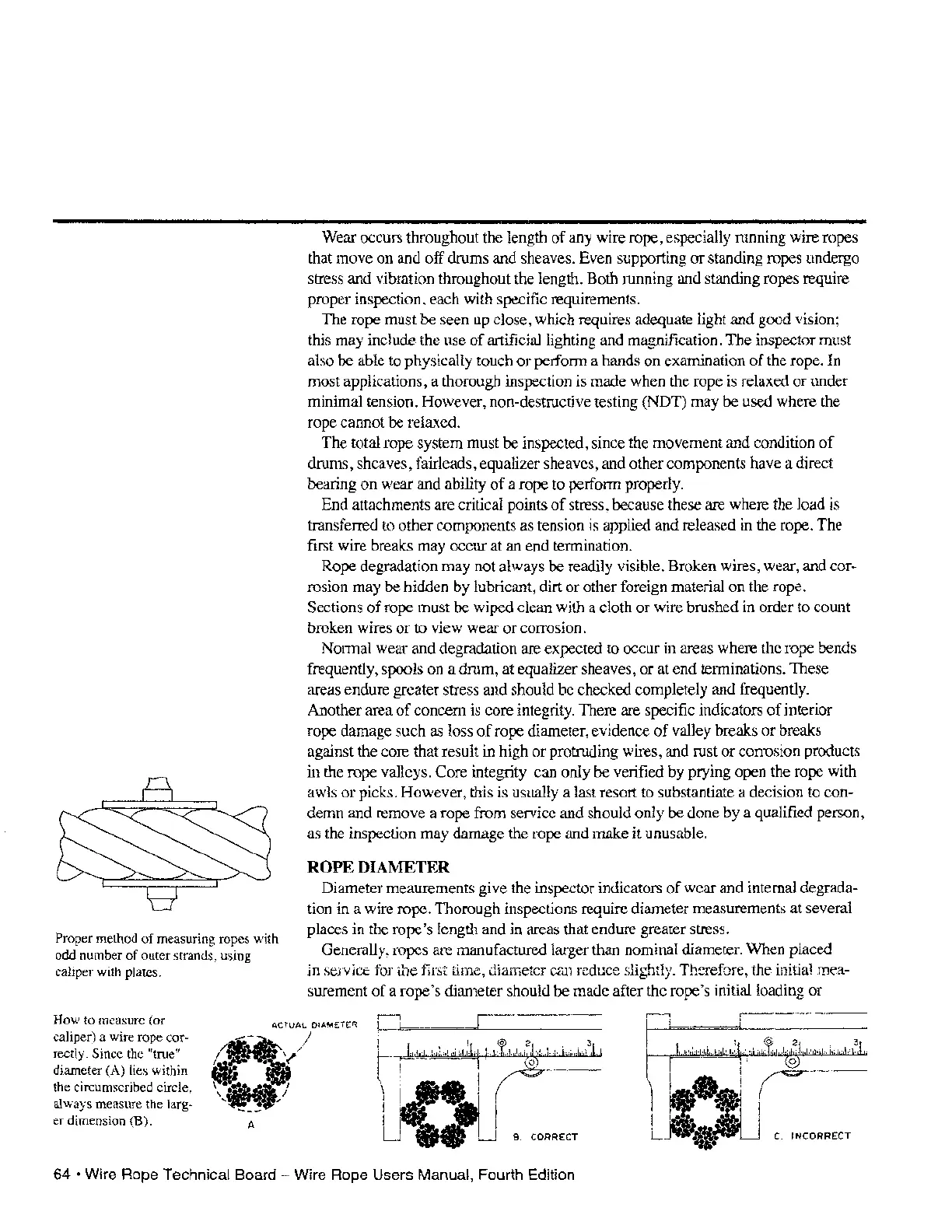

ROPE

DIAMETER

Diameter meaurements give

the

inspector indicators of wear and internal degrada-

tion in a

wire

rope. Thorough inspections require diameter measurements

at

several

places in

the

rope's length and

in

areas

that endure greater stress.

Generally, ropes are manufactured larger than nominal

diameter.

When placed

in

service

for

t'1e

first time, diameter can reduce

slig;.~t1y.

Therefore,

the

initial

mea-

surement of a rope's diameter should

be

made

after

the

rope's initial loading or

How to measure (or

caliper) a wire rope

cor-

rectly. Since the "true"

diameter (A) lies within

the circumscribed circle,

always measure the

larg-

er dimension (B).

ACTUAL DIAMETER

~/

~"(!~~-

\ I

, /

---

A

C.

INCORRECT

64'

Wire Rope Technical Board - Wire Rope Users Manual, Fourth Edition

Loading...

Loading...