breaking in period (see pg 25-26 for more information). That is the measurement to

be recorded

as

the initial diameter.

The actual rope diameter must be measured. This is defined as the diameter

of

the

circumscribing circle. (ie, its largest cross sectional dimension)

To

insure accuracy

this measurement should be made with a wire rope caliper using the correct method

(b) shown on the facing page. Special techniques and equipment must be employed

for measuring ropes with an odd number

of

outer strands. (eg, circumferential tapes,

calipers with plates

- see illustration on facing page).

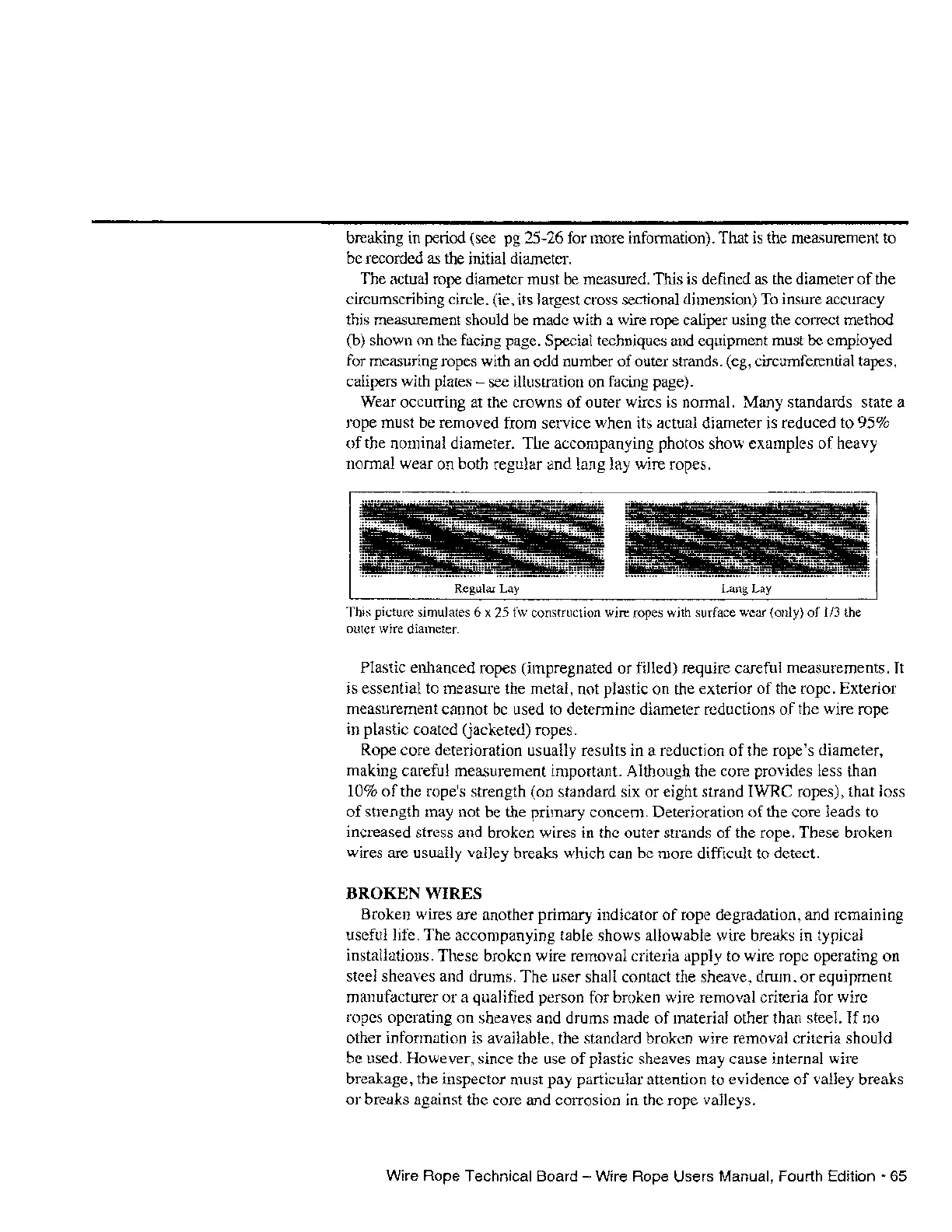

Wear occurring at the crowns

of

outer wires is normal. Many standards state a

rope must be removed from service when its actual diameter is reduced to 95%

of

the nominal diameter. The accompanying photos show examples

of

heavy

normal wear on both regular and lang lay wire ropes.

Regular Lay Lang Lay

This picture simulates 6 x

25

fw construction wire ropes with surface wear (only)

of

113

the

outer wire diameter.

Plastic enhanced ropes (impregnated or filled) require careful measurements.

It

is essential to measure the metal, not plastic on the exterior

of

the rope. Exterior

measurement cannot be used to determine diameter reductions

of

the wire rope

in plastic coated (jacketed) ropes.

Rope core deterioration usually results in a reduction

of

the rope's diameter,

making careful measurement important. Although the core provides less than

10%

of

the rope's strength (on standard six

or

eight strand IWRC ropes), that loss

of

strength may not be the primary concern. Deterioration

of

the core Jeads to

increased stress and broken wires in the outer strands

of

the rope. These broken

wires are usually valley breaks which can be more difficult to detect.

BROKEN WIRES

Broken wires are another primary indicator

of

rope degradation, and remaining

useful life. The accompanying table shows allowable wire breaks in typical

installations. These broken wire removal criteria apply to wire rope operating on

steel sheaves and drums. The user shall contact the sheave, drum,

or

equipment

manufacturer

or

a qualified person for broken wire removal criteria for wire

ropes operating on sheaves and drums made

of

material other than steel.

If

no

other information is available, the standard broken wire removal criteria should

be used. However, since the use

of

plastic sheaves may cause internal wire

breakage, the inspector must pay particular attention to evidence

of

valley breaks

or breaks against the core and corrosion in the rope valleys.

Wire Rope Technical Board - Wire Rope Users Manual, Fourth

Edition·

65

Loading...

Loading...