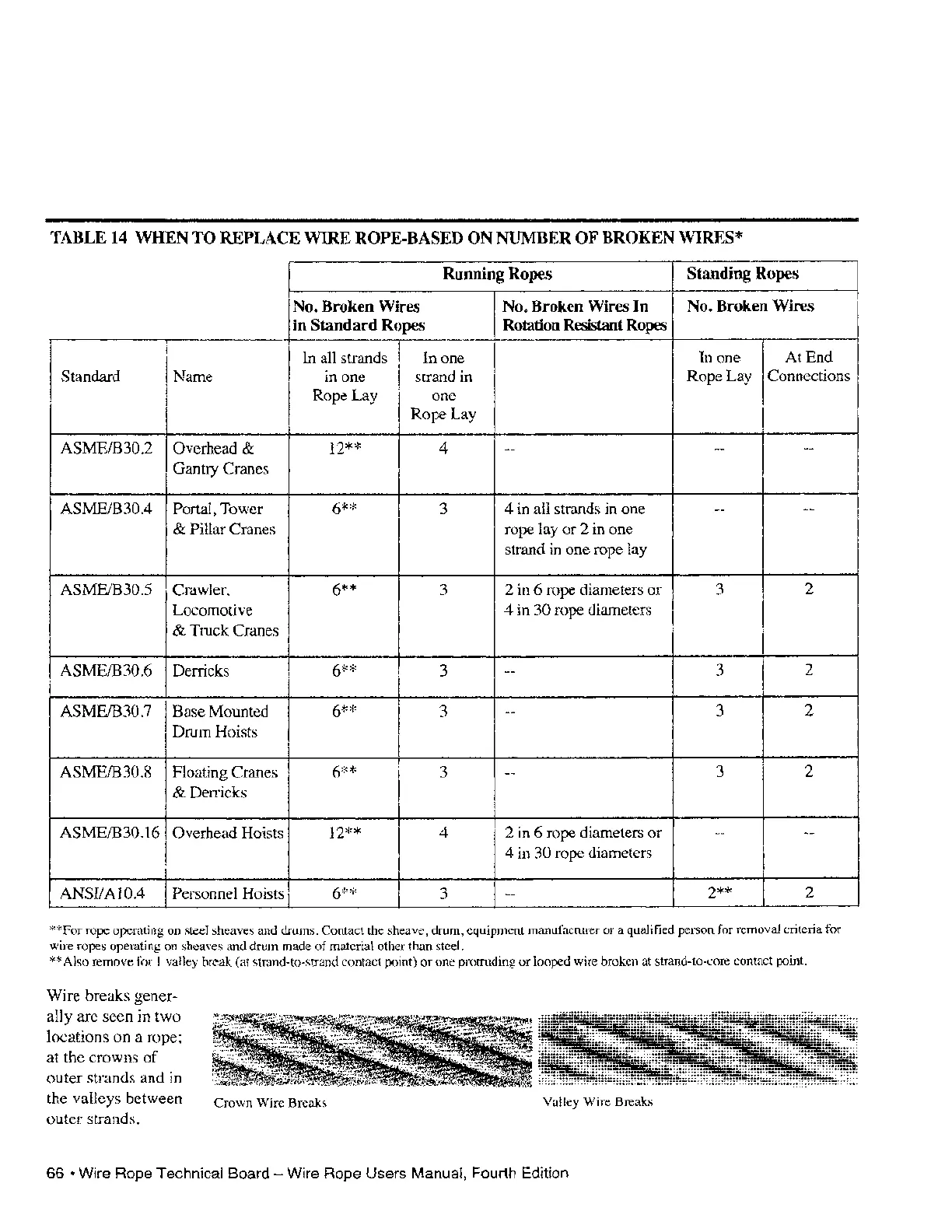

TABLE

14

WHEN

TO

REPLACE

WIRE

ROPE-BASED

ON

NUMBER

OF

BROKEN

WIRES*

Running

Ropes

Standing

Ropes

No. Broken

Wires

No.

Broken

Wires

In

No. Broken

Wires

in

Standard Ropes

Rotation

Resistant

Ropes

In all strands

In

one

In one

At End

Standard Name

in one strand

in

Rope Lay

Connections

Rope Lay one

Rope Lay

ASMEIB30.2

Overhead & 12** 4

--

--

--

Gantry Cranes

ASME/B30A

Portal, Tower

6**

3

4 in all strands in one

--

--

& Pillar Cranes

rope lay or 2

in

one

strand in one rope lay

ASME/B30.5

Crawler,

6**

3

2 in 6 rope diameters or 3

2

Locomotive

4 in

30 rope diameters

& Truck Cranes

ASMEIB30.6

Derricks

6**

3

--

3

2

ASMEIB30.7 Base Mounted

6**

3

--

3

2

Drum Hoists

ASMEIB30.8 Floating Cranes 6** 3

--

3

2

& Derricks

ASMEIB30.16 Overhead Hoists

12**

4 2 in 6 rope diameters or

--

--

4 in 30 rope diameters

ANSI/AlOA

Personnel Hoists

6**

3

--

2**

2

**For rope operating

on

steel sheaves and drums. Contact the sheave, drum, equipment manufacturer or a qualified person for removal criteria for

wire ropes operating on sheaves and drum made

of

material other than steel.

** Also remove for 1 vaney break (at strand-to-strand contact point)

or

one protruding or looped wire broken at

strand-t~-core

contact point.

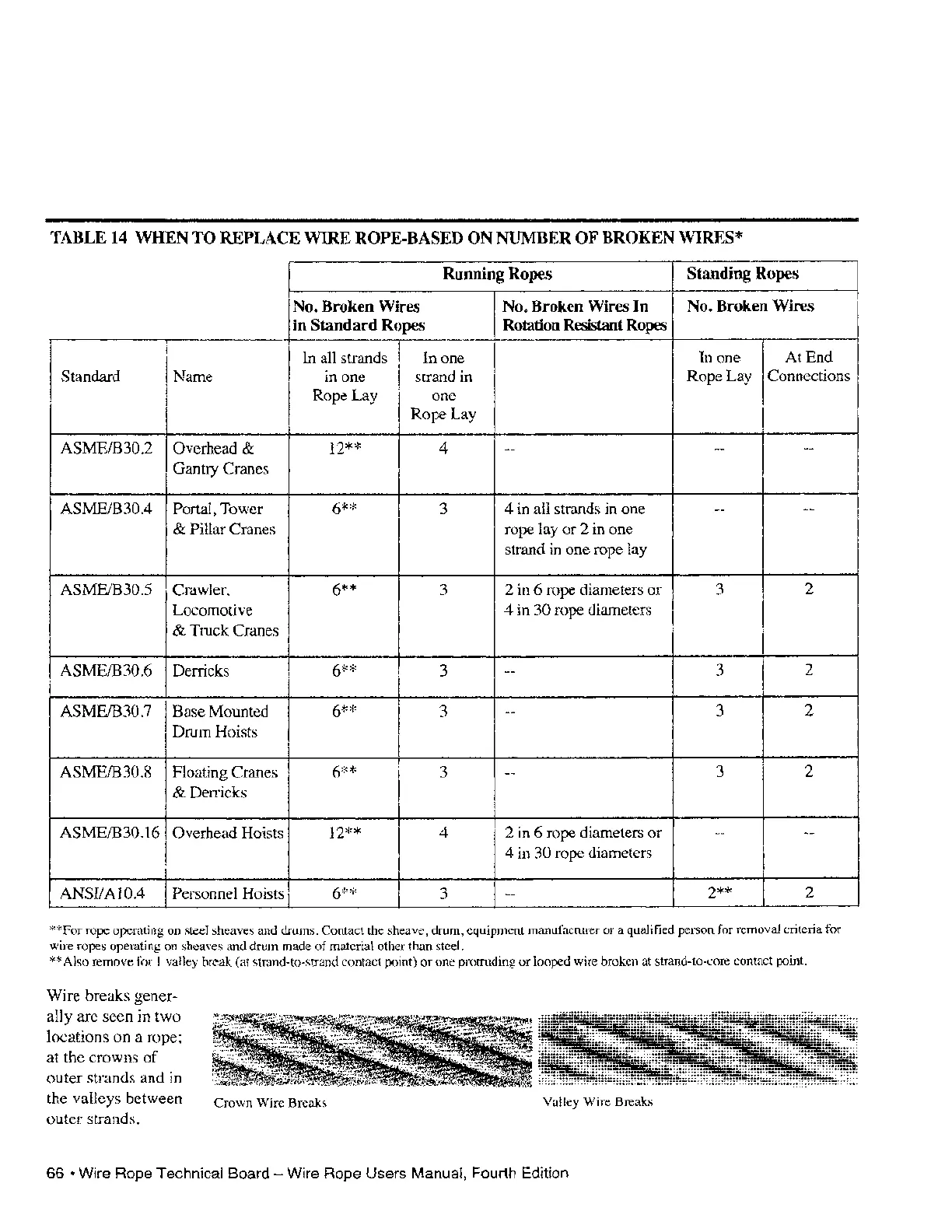

Wire breaks gener-

ally are seen in two

locations on a rope;

at the crowns

of

outer

strands and in

the valleys between

outer strands.

Crown

Wire

Breaks

Valley Wire Breaks

66 • Wire Rope Technical Board - Wire Rope Users Manual, Fourth Edition

Loading...

Loading...