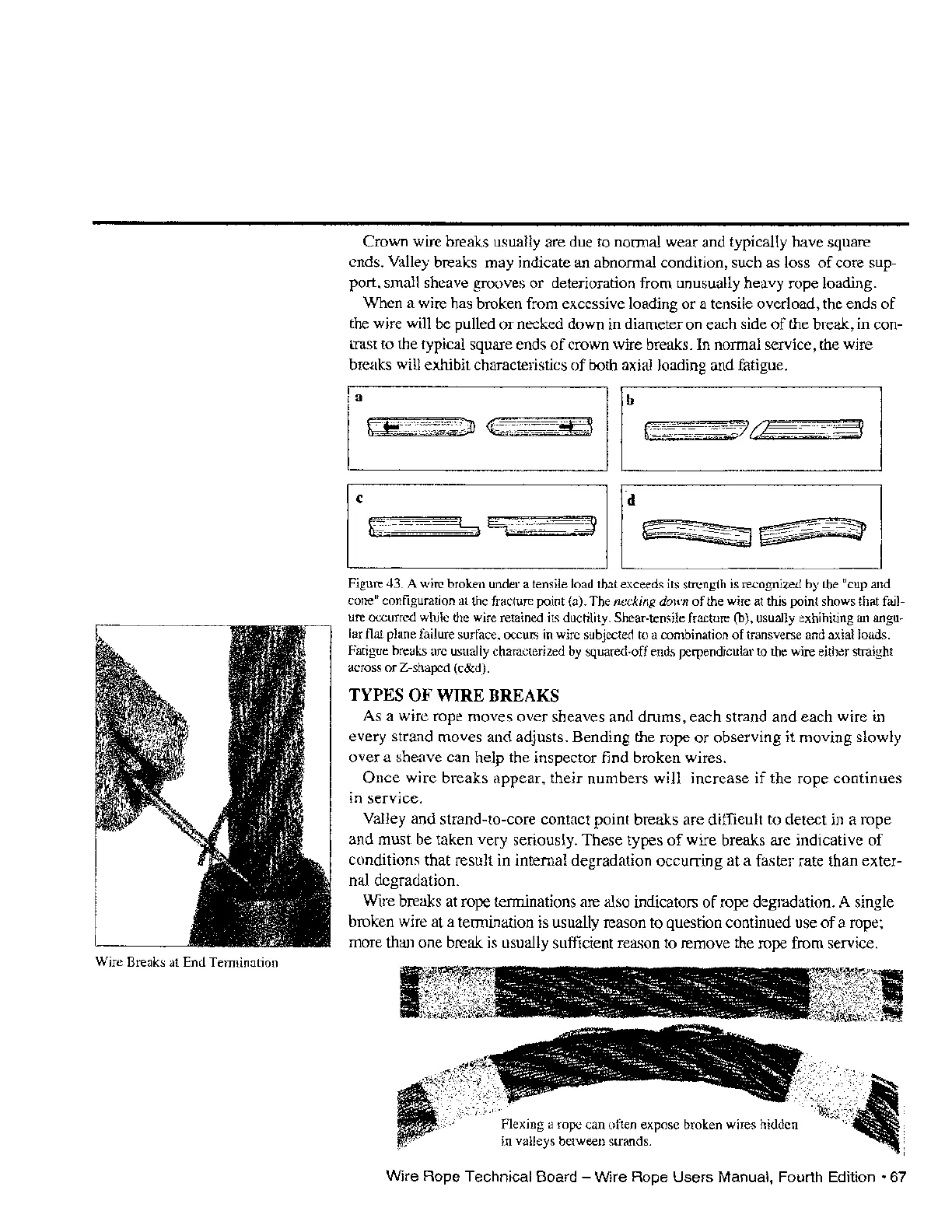

Wire Breaks at

End

Termination

Crown wire breaks usually are due to normal wear and typically have square

ends. Valley breaks may indicate an abnormal condition, such as loss

of

core sup-

port, small sheave grooves

or

deterioration from unusually heavy rope loading.

When a wire has broken from excessive loading or a tensile overload, the ends

of

the wire will be pulled or necked down in diameter on each side

of

the break, in con-

trast to the typical square ends

of

crown wire breaks. In normal service, the wire

breaks will exhibit

characteristics

of

both axial loading and fatigue.

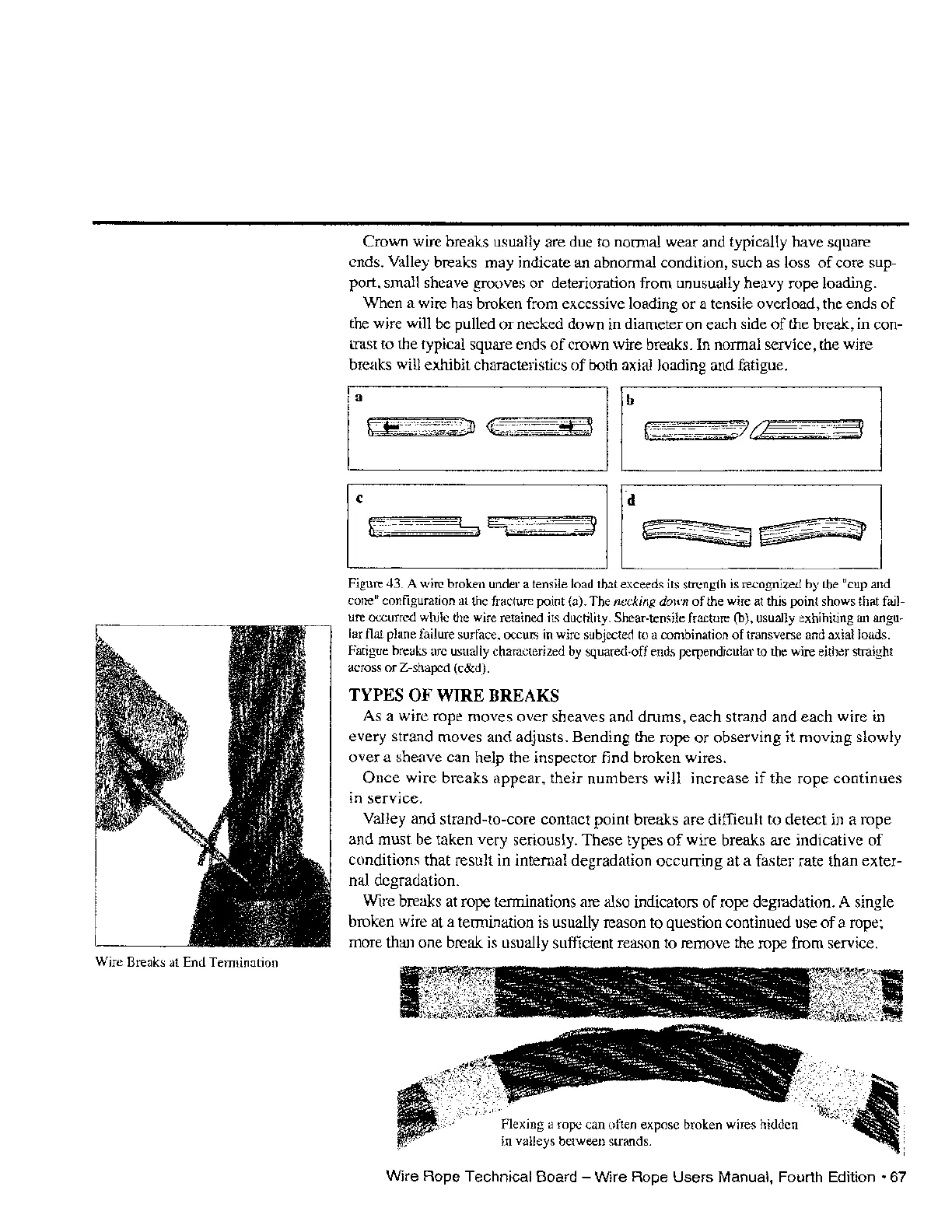

rt:

E

Figure 43. A wire broken under a tensile load that exceeds its strength is recognized

by

the "cup and

cone" configuration at the fracture point (a). The necking down

of

the wire at this point shows that fail-

ure occurred while the wire retained its ductility. Shear-tensile fracture

(b), usually exhibiting an angu-

Jar

flat plane failure surface, occurs in wire subjected to a combination

of

transverse and axial loads .

Fatigue breaks are usually characterized by squared-off ends perpendicular to the wire either straight

across

or

Z-shaped (c&d).

TYPES OF WIRE BREAKS

As a wire rope moves over sheaves and drums, each strand and each wire

in

every strand moves and adjusts. Bending the rope

or

observing

it

moving slowly

over a sheave can help the inspector find broken wires.

Once

wire breaks appear,

their

numbers will increase

if

the

rope

continues

in service.

Valley and strand-to-core contact point breaks are difficult to detect in a rope

and must be taken very seriously. These types

of

wire breaks are indicative

of

conditions that result in internal degradation occurring at a faster rate than exter-

nal degradation.

Wire breaks at rope terminations are also indicators

of

rope degradation. A single

broken wire at a termination is usually reason to question continued use

of

a rope;

more than one break is usually sufficient reason to remove the rope from service.

Flexing a rope can often expose broken wires hidden

in valleys between strands.

Wire Rope Technical Board - Wire Rope Users Manual, Fourth

Edition·

67

Loading...

Loading...