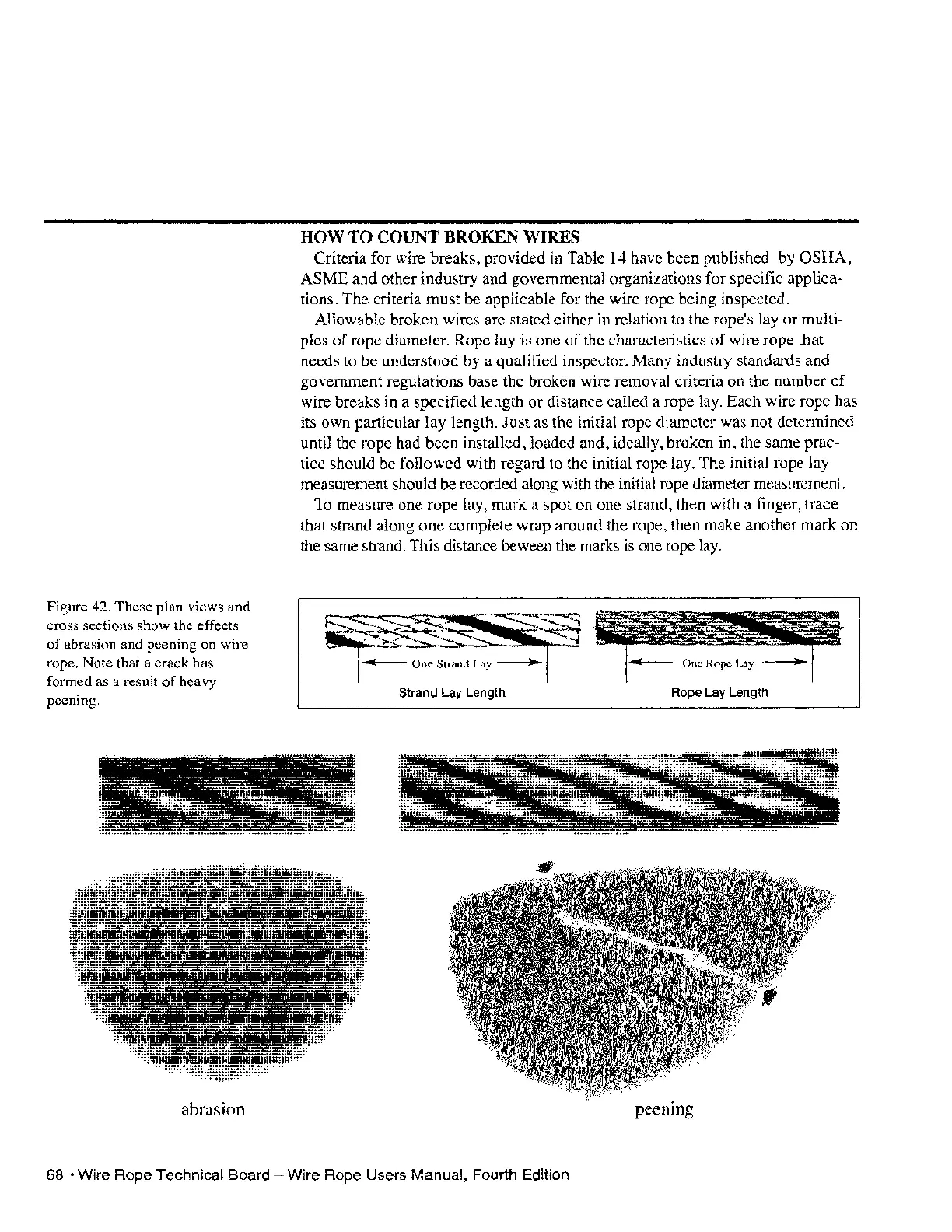

Figure 42. These plan views and

cross sections show the effects

of

abrasion and peening on wire

rope. Note that a crack has

formed as a result

of

heavy

peening.

abrasion

HOW

TO COUNT BROKEN WIRES

Criteria for wire breaks, provided in Table 14 have been published

by

OSHA,

ASME

and other industry and govemmental organizations for specific applica-

tions.

The

criteria

must

be applicable for the wire rope being inspected.

Allowable

broken

wires are stated either in relation to the rope's lay

or

multi-

ples

of

rope

diameter.

Rope

lay

is one

of

the characteristics

of

wire rope that

needs to

be

understood

by

a qualified inspector. Many industry standards and

government regulations base the broken wire removal criteria

on

the number

of

wire breaks in a specified length

or

distance called a rope lay. Each wire rope has

its

own

particular

lay

length. Just as the initial rope diameter was not determined

until the rope had

been

installed, loaded and, ideally, broken in, the same prac-

tice should

be

followed with regard to the initial rope lay. The initial rope lay

measurement should

be

recorded along with the initial rope diameter measurement.

To measure

one

rope

lay,

mark

a spot

on

one strand, then with a finger, trace

that strand along

one

complete wrap around the rope, then make another mark on

the same strand. This distance beween the marks is one rope lay.

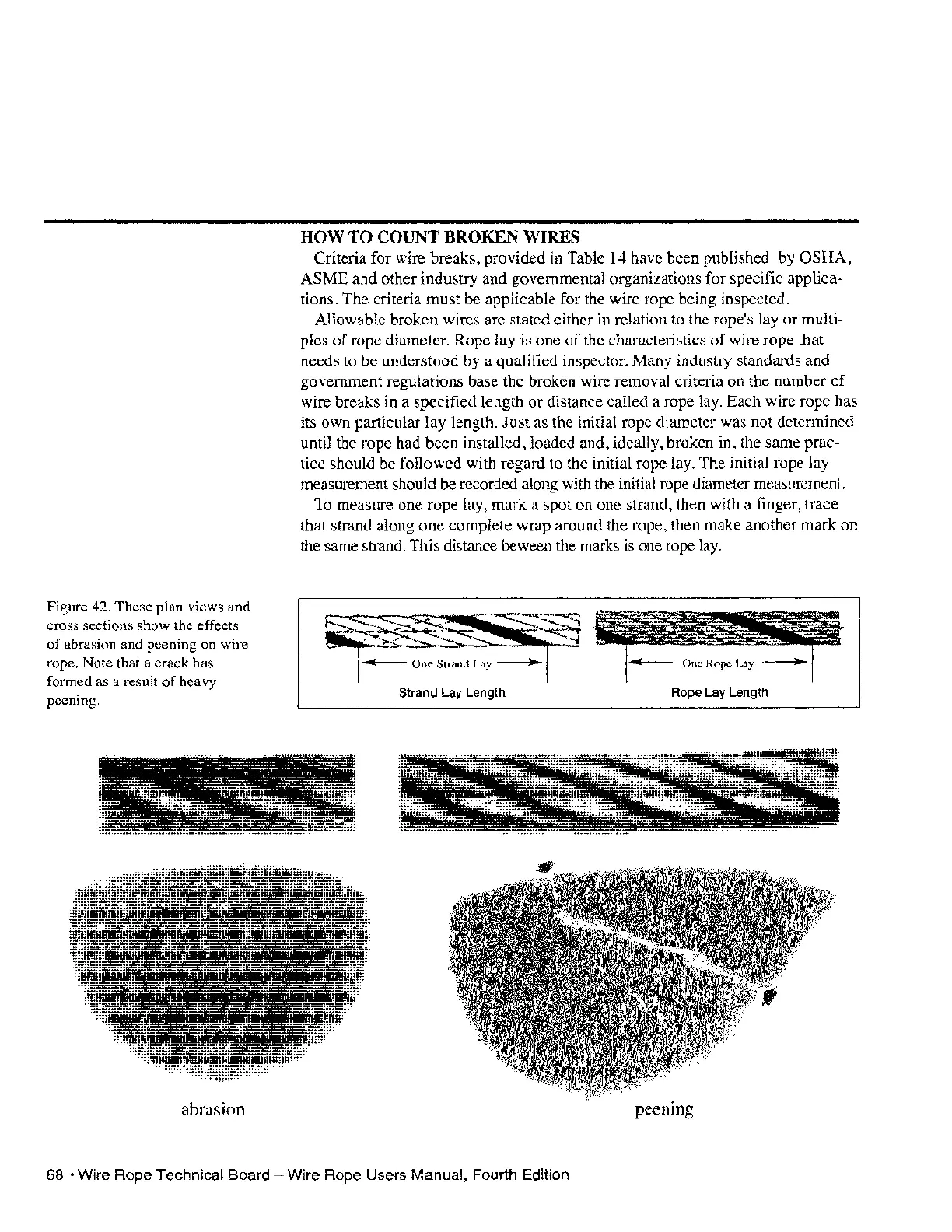

Strand Lay Length

Rope Lay Length

peening

68 • Wire Rope Technical Board - Wire Rope Users Manual, Fourth Edition

Loading...

Loading...