6x26

Warrington Seale

Compacted Strand

IWRC

8x26

Warrington Seale

Compacted Strand

IWRC

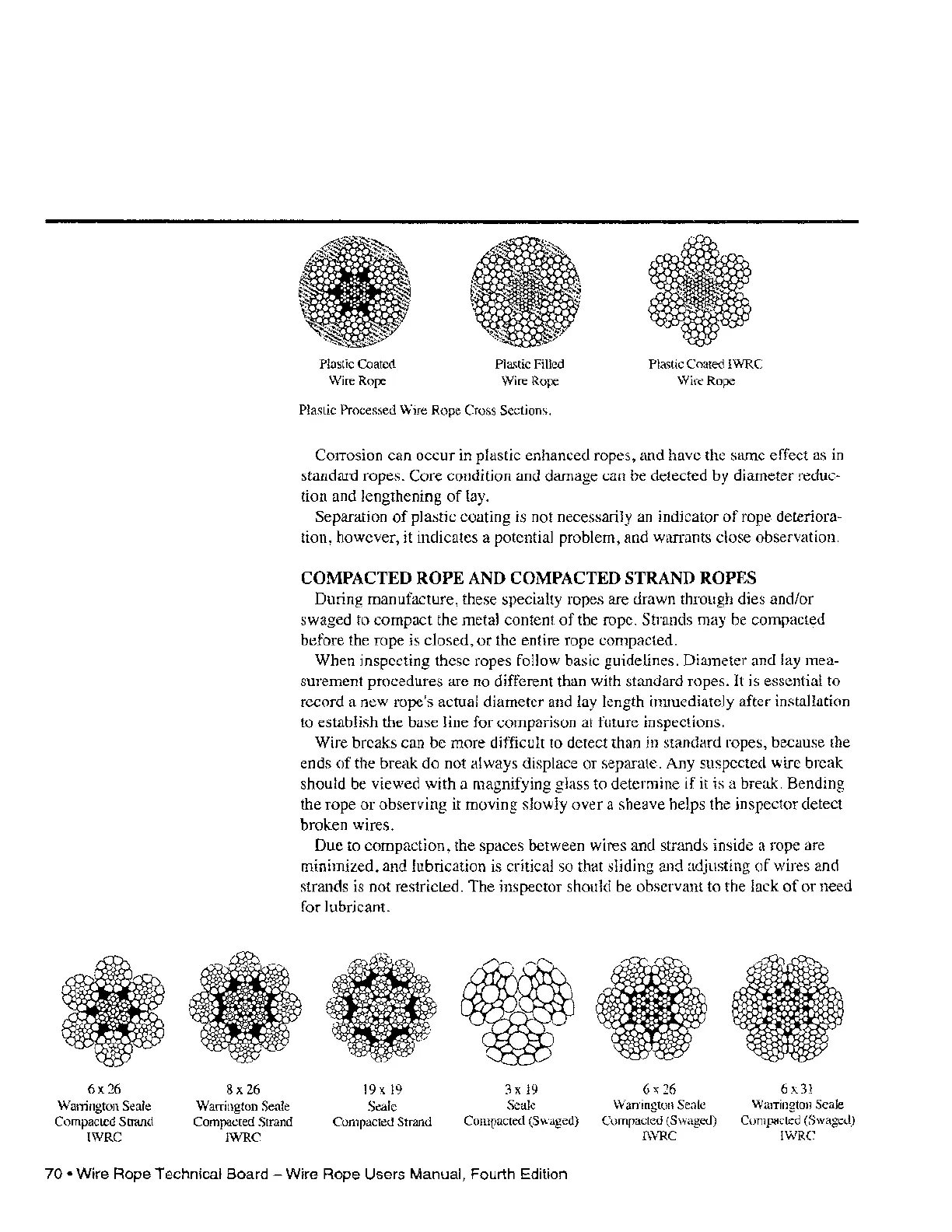

Plastic Coated

Wire Rope

Plastic Filled

Wire Rope

Plastic Processed

Wire

Rope

Cross

Sections.

Plastic Coated

IWRC

Wire Rope

Corrosion can occur

in

plastic enhanced ropes, and have the same effect as in

standard ropes. Core condition and damage can be detected by diameter reduc-

tion and lengthening

of

lay.

Separation

of

plastic coating is not necessarily an indicator

of

rope deteriora-

tion, however, it indicates a potential problem, and warrants close observation.

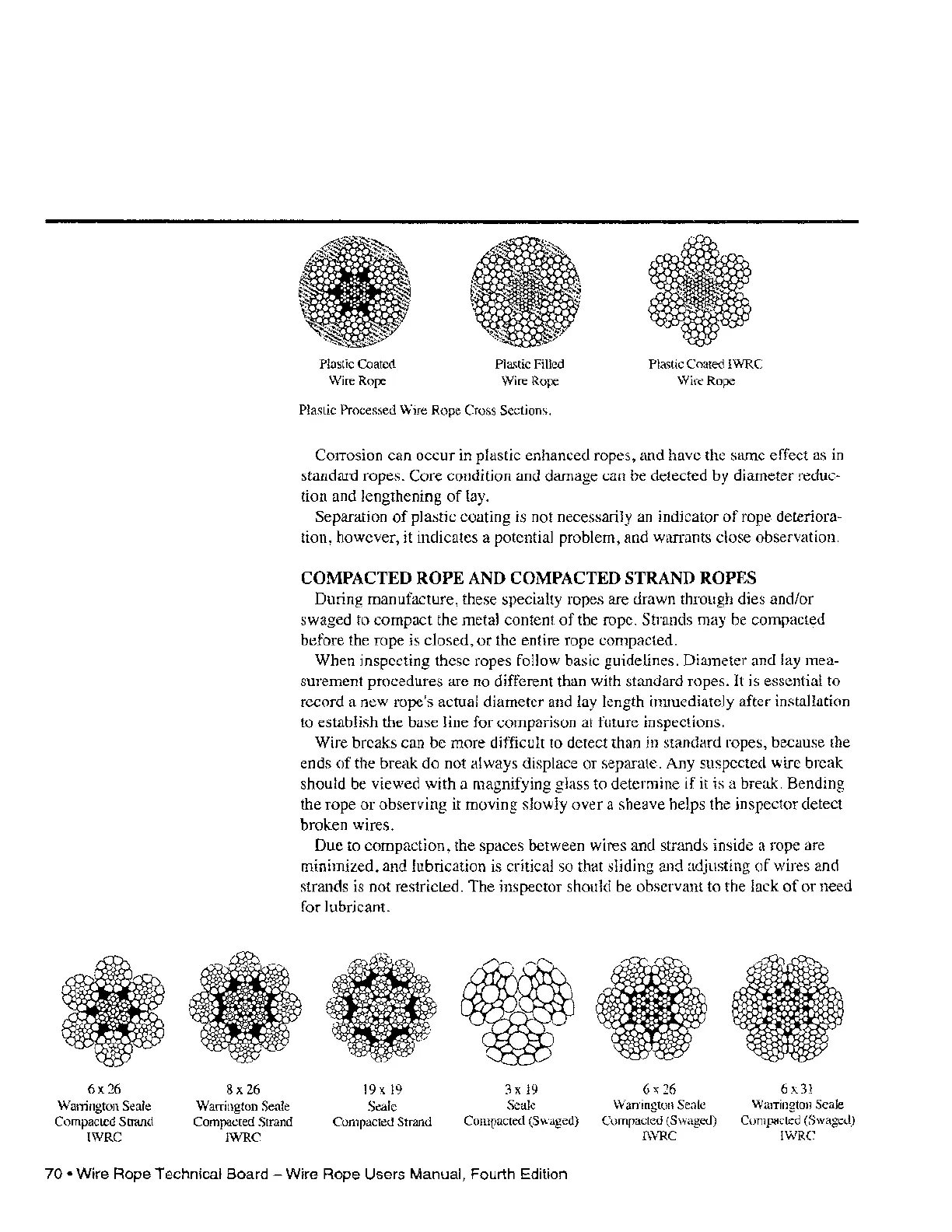

COMPACTED

ROPE AND COMPACTED STRAND ROPES

During manufacture, these specialty ropes are drawn through dies and/or

swaged to compact the metal content

of

the rope. Strands may be compacted

before the rope

is

closed, or the entire rope compacted.

When inspecting these ropes follow basic guidelines. Diameter and lay mea-

surement procedures are no different than with standard ropes.

It

is essential to

record a new rope's actual diameter and lay length immediately after installation

to establish the base line for comparison at future inspections.

Wire breaks can

be

more difficult to detect than in standard ropes, because the

ends

of

the break

do

not always displace or separate. Any suspected wire break

should be viewed with a magnifying glass to determine

if

it is a break. Bending

the rope or observing it moving slowly over a sheave helps the inspector detect

broken wires.

Due to compaction, the spaces between wires and strands inside a rope are

minimized, and lubrication is critical so that sliding and adjusting

of

wires and

strands is not restricted. The inspector should be observant to the lack

of

or need

for lubricant.

19x

19

Seale

Compacted Strand

3 x

19

Seale

Compacted (Swaged)

6x26

Wanington Seale

Compacted (Swaged)

IVVRC

6x31

WalTington Seale

Compacted (Swaged)

IWRC

70

• Wire Rope Technical Board - Wire Rope Users Manual, Fourth Edition

Loading...

Loading...