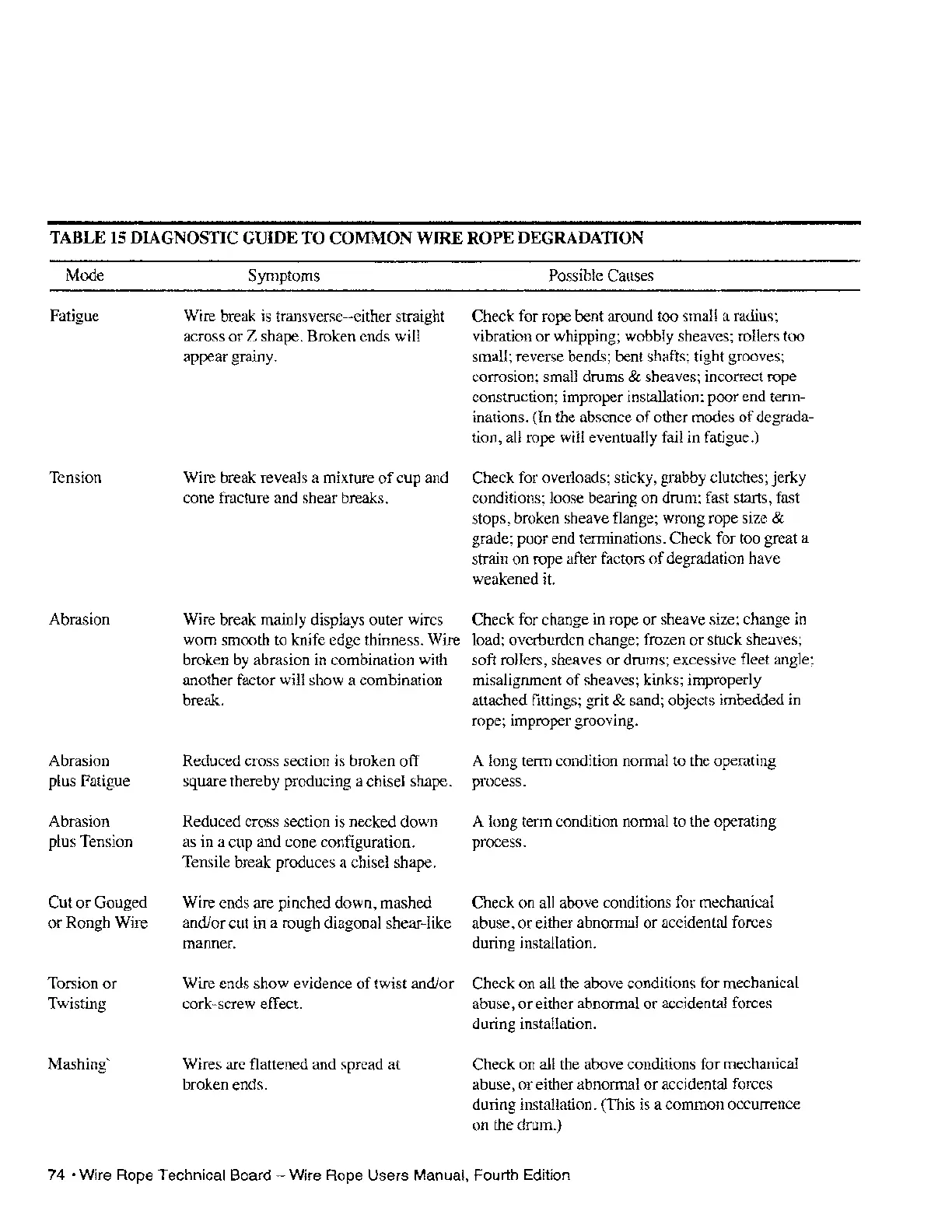

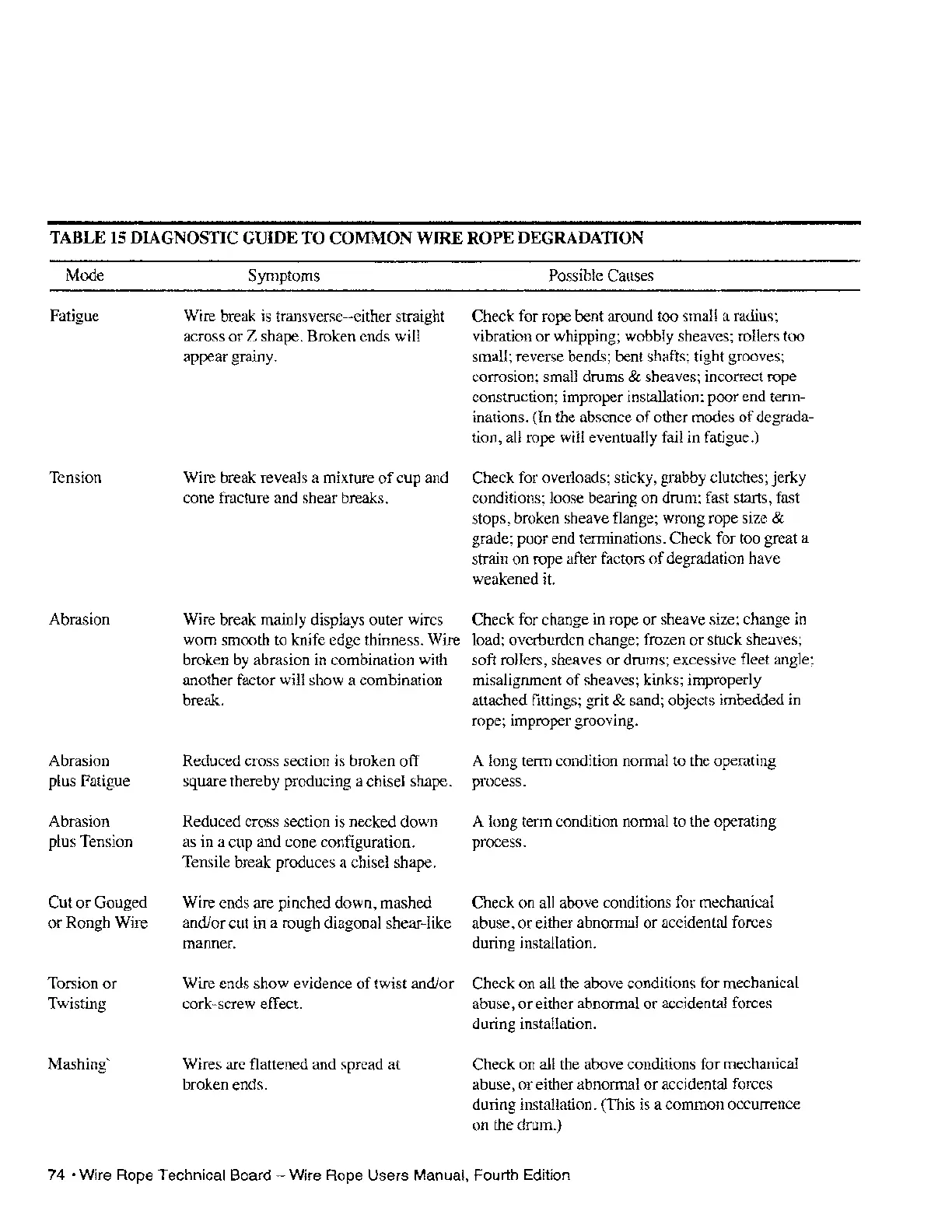

TABLE

15

DIAGNOSTIC

GUIDE

TO

COMMON

WIRE

ROPE

DEGRADATION

Mode

Fatigue

Tension

Abrasion

Abrasion

plus Fatigue

Abrasion

plus Tension

Cut

or

Gouged

or

Rough Wire

Torsion

or

Twisting

Mashing'

Symptoms

Wire break is transverse--either straight

across

or

Z shape. Broken ends will

appear grainy.

Wire break reveals a mixture

of

cup and

cone fracture and shear breaks.

Wire break mainly displays outer wires

worn smooth to knife edge thinness. Wire

broken by abrasion in combination with

another factor will show a combination

break.

Reduced cross section is broken

off

square thereby producing a chisel shape.

Reduced cross section is necked down

as in a cup and cone configuration.

Tensile break produces a chisel shape.

Wire ends are pinched down, mashed

and/or cut in a rough diagonal shear-like

manner.

Possible Causes

Check for rope bent around too small a radius;

vibration

or

whipping; wobbly sheaves; rollers too

small; reverse bends; bent shafts; tight grooves;

corrosion; small drums

& sheaves; incorrect rope

construction; improper installation; poor end term-

inations. (In the absence

of

other modes

of

degrada-

tion, all rope will eventually fail in fatigue.)

Check for overloads; sticky, grabby clutches; jerky

conditions; loose bearing

on

drum; fast starts, fast

stops, broken sheave flange; wrong rope size

&

grade; poor end terminations. Check for too great a

strain

on

rope after factors

of

degradation have

weakened

it.

Check for change in rope

or

sheave size; change in

load; overburden change; frozen

or

stuck sheaves;

soft rollers, sheaves

or

drums; excessive fleet angle;

misalignment

of

sheaves; kinks; improperly

attached fittings; grit

& sand; objects imbedded in

rope; improper grooving.

A long term condition normal to the operating

process.

A long term condition normal to the operating

process.

Check on all above conditions for mechanical

abuse,

or

either abnormal

or

accidental forces

during installation.

Wire ends show evidence

of

twist and/or Check

on

all the above conditions for mechanical

cork -screw effect.

Wires are flattened and spread at

broken ends.

abuse,

or

either abnormal

or

accidental forces

during installation.

Check on all the above conditions for mechanical

abuse, or either abnormal

or

accidental forces

during installation. (This is a common occurrence

on

the drum.)

74 • Wire Rope Technical Board - Wire Rope Users Manual, Fourth Edition

Loading...

Loading...