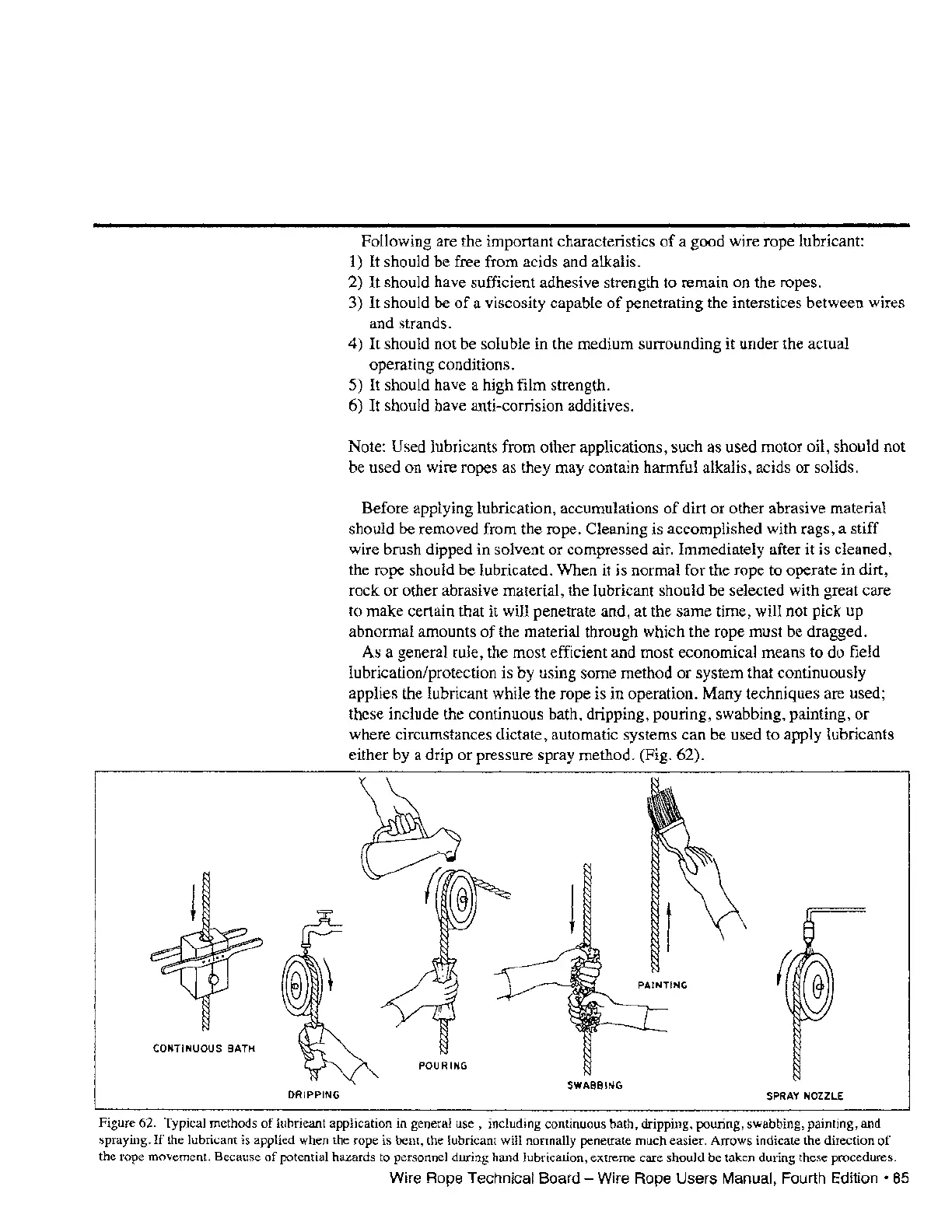

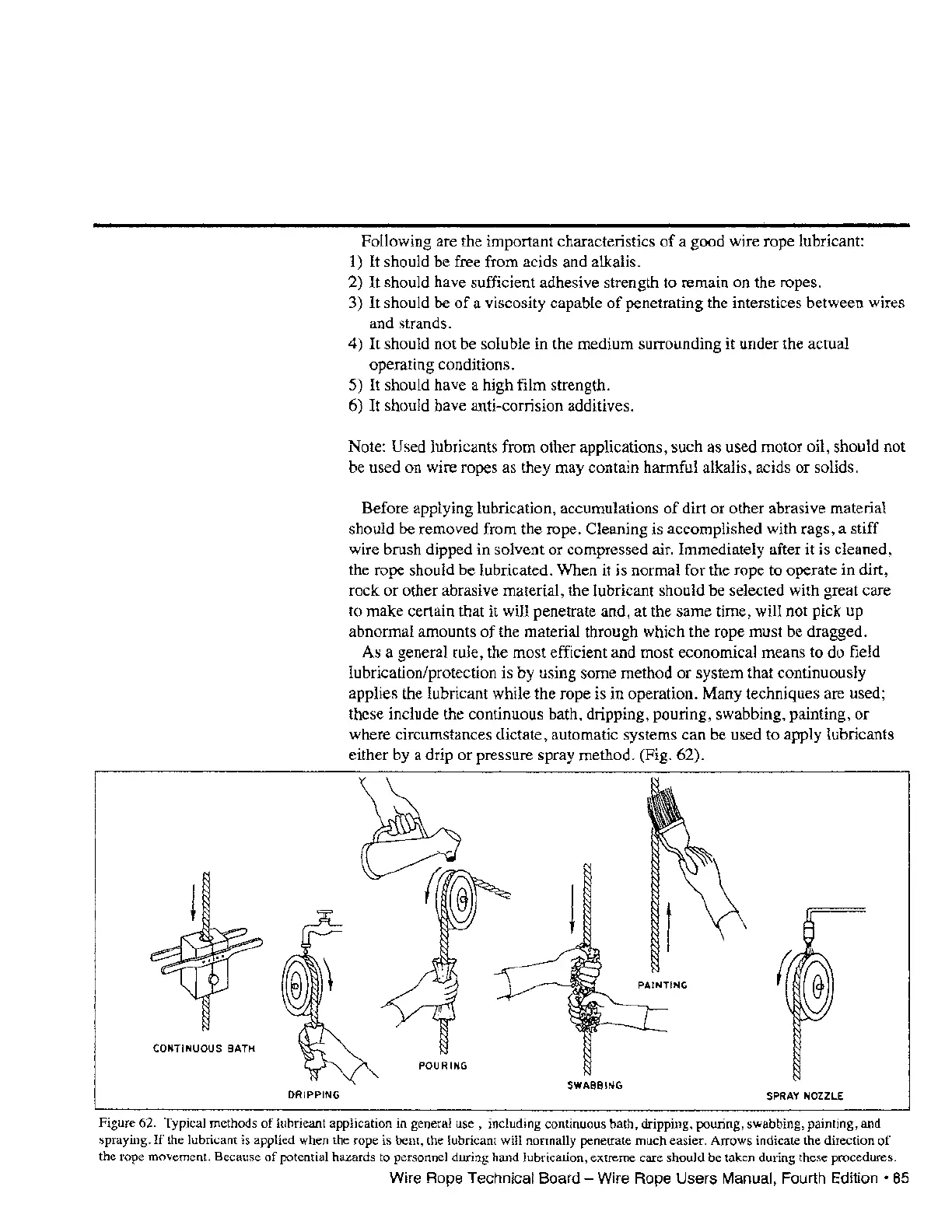

CONTINUOUS BATH

DRIPPING

Following are the important characteristics

of

a good wire rope lubricant:

1)

It

should be free from acids and alkalis.

2)

It

should have sufficient adhesive strength to remain on the ropes.

3)

It

should be

of

a viscosity capable

of

penetrating the interstices between wires

and strands.

4)

It

should not be soluble in the medium surrounding it under the actual

operating conditions.

5) It should have a high film strength.

6) It should have anti-corrision additives.

Note: Used lubricants from other applications, such as used motor oil, should not

be used on wire ropes as they may contain harmful alkalis, acids or solids.

Before applying lubrication, accumulations

of

dirt or other abrasive material

should be removed from the rope. Cleaning is accomplished with rags, a stiff

wire brush dipped in solvent

or

compressed air. Immediately after it is cleaned,

the rope should be lubricated. When it is normal for the rope to operate in dirt,

rock or other abrasive material, the lubricant should be selected with great care

to make certain that it will penetrate and, at the same time, will not pick up

abnormal amounts

of

the material through which the rope must be dragged.

As a general rule, the most efficient and most economical means to do field

lubrication/protection is

by

using some method

or

system that continuously

applies the lubricant while the rope is in operation. Many techniques are used;

these include the continuous bath, dripping, pouring, swabbing, painting,

or

where circumstances dictate, automatic systems can be used to apply lubricants

either

by

a drip or pressure spray method. (Fig. 62).

POURING

SWABBING

SPRAY

NOZZLE

Figure 62. Typical methods

of

lubricant application in general

use,

including continuous bath, dripping, pouring, swabbing, painting, and

spraying.

If

the lubricant is applied when the rope is bent, the lubricant will normally penetrate much easier. Arrows indicate the direction

of

the rope movement. Because

of

potential hazards to personnel during hand lubrication, extreme care should be taken during these procedures.

Wire Rope Technical Board - Wire Rope Users Manual, Fourth

Edition·

85

Loading...

Loading...