4GENERAL INFORMATION

1.4 SYSTEM ACCESSORIES

SC2/XR Standoff Control - For machine mounted torches,

the SC2/XR automatically maintains torch standoff by

controlling a customer-supplied torch lifter motor.

Cylinder Rack Running Gear - For transporting up to two

full-sized gas cylinders along with the system.

Computer Control Cable Kit - For interfacing the power

supply with a computer or auxiliary control device.

High Pressure Gas Regulators - Available for air, argon/

hydrogen, nitrogen, and CO2.

Service Parts Kit - Provides spare power supply parts for

service activities in remote areas.

Front Mount Regulator Kit - Allows convenient access to

air line regulators from front of unit.

See page 38 for ordering information.

Air/Multi-Gas Gouging Parts Kit - Everything needed to

add gouging capabilities to the cutting system.

Remote Pendant Control - For remote control operation of

machine torch systems.

Circle Cutter Attachment - Manual torch guide extends for

cuts from 2.25 in (57 mm) to 24 in (610 mm) in diameter.

Also available: 12 in (305 mm) extension rod

Leads Extension Packages - Available in 25 ft (7.6 m) or

50 ft (15.2 m) lengths. For extending leads up to a

maximum of 100 ft (30.5 m).

See page 37 for ordering information.

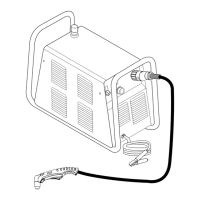

Power Supply Accessories

Torch Accessories

Plasma Gas Flow Plasma is defined as a gas which has been heated to an

extremely high temperature and ionized so that it becomes

electrically conductive. The plasma arc cutting and goug-

ing processes use this plasma to transfer an electric arc to

the workpiece. The metal to be cut or removed is melted

by the heat of the arc and then blown away.

While the goal of plasma arc cutting is severance of the

material, plasma arc gouging is used to remove metals to a

controlled depth and width.

In a plasma cutting torch, a cool gas such as air or nitrogen

(N2) enters Zone B (Figure 1-D), where a pilot arc between

the electrode and the torch tip heats and ionizes the gas.

The main cutting arc then transfers to the workpiece

through the column of plasma gas in Zone C.

By forcing the plasma gas and electric arc through a small

orifice, the torch delivers a high concentration of heat to a

small area. The stiff, constricted plasma arc is shown in

Zone C (Figure 1-D). Direct current (DC) straight polarity

is used for plasma cutting, as shown in the illustration.

1.5 THEORY OF OPERATION

Loading...

Loading...