24

When hand cutting, cutting speeds primarily depend on

the material being cut, the thickness, and how fast the

operator can comfortably and accurately follow the line.

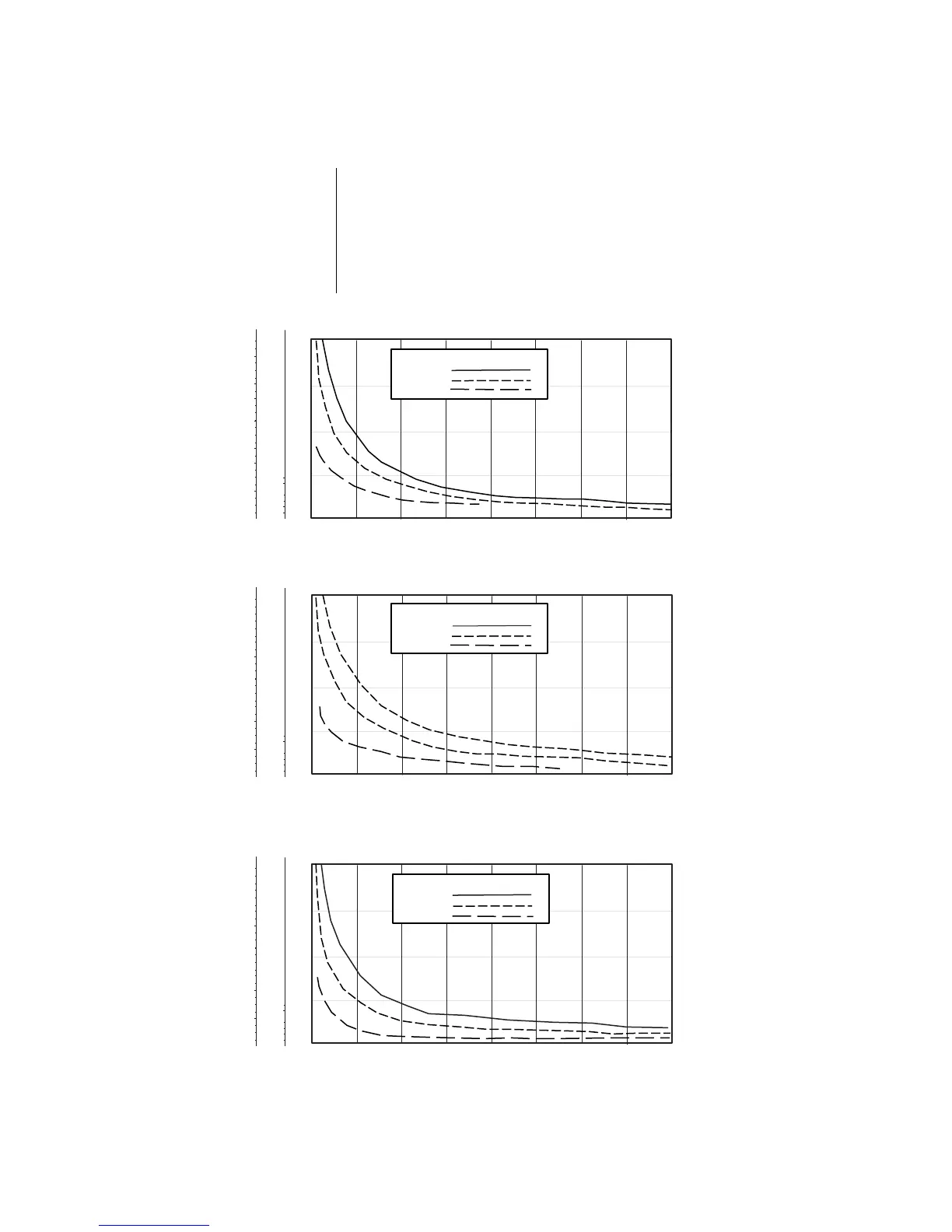

The following charts show optimum cutting speed ranges

for most materials using a machine torch with air plasma/

air secondary and nitrogen plasma/CO2 secondary. The

data was obtained using 1/8 in (3 mm) standoff.

3.7 CUTTING SPEEDS

Figure 3-H PAK 1250 XR Cutting Speeds - Air Operation

OPERATION

AIR/AIR ON MILD STEEL

Range III

Range II

Range I

Inches per Minute 50 100 150 200 250 300 350 400

Meters per Minute 1.27 2.54 3.81 5.08 6.35 7.62 8.89 10.16

(mm) (gage) (in)

1.00

0.75

0.50

0.25

0.125

0.62

MATERIAL THICKNESS

25

20

15

10

5

4

8

12

16

CUTTING SPEED

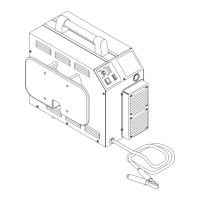

AIR/AIR ON ALUMINUM

Range III

Range II

Range I

Inches per Minute 50 100 150 200 250 300 350 400

Meters per Minute 1.27 2.54 3.81 5.08 6.35 7.62 8.89 10.16

(mm) (gage) (in)

1.00

0.75

0.50

0.25

0.125

0.62

MATERIAL THICKNESS

25

20

15

10

5

4

8

12

16

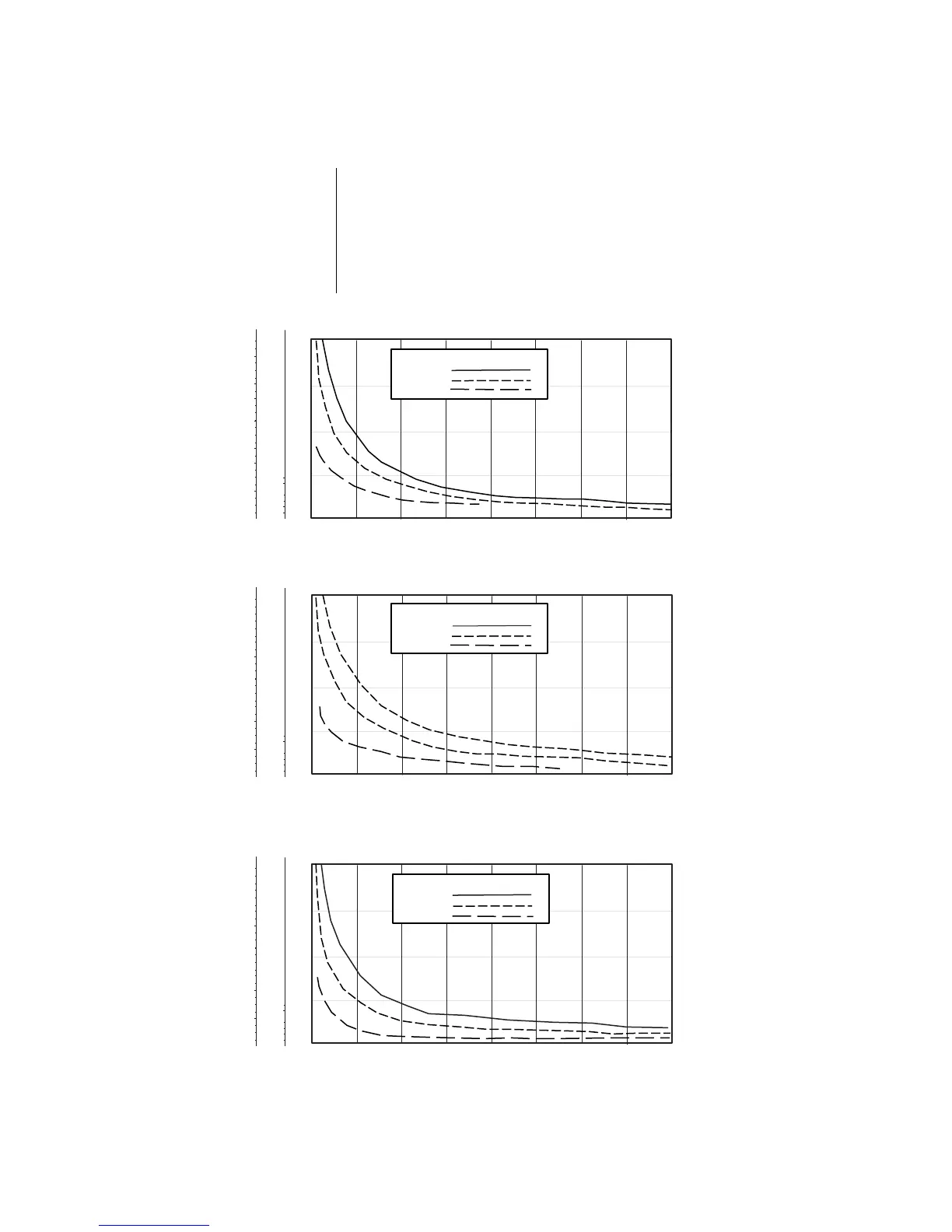

AIR/AIR ON STAINLESS

Range III

Range II

Range I

Inches per Minute 50 100 150 200 250 300 350 400

Meters per Minute 1.27 2.54 3.81 5.08 6.35 7.62 8.89 10.16

(mm) (gage) (in)

1.00

0.75

0.50

0.25

0.125

0.62

MATERIAL THICKNESS

25

20

15

10

5

4

8

12

16

A-01478

CUTTING SPEED

CUTTING SPEED

Loading...

Loading...