25

3.7 CUTTING SPEEDS (continued)

This information represents realistic expectations using

recommended practices and well maintained systems.

Actual speeds may vary up to 50% from those shown.

Factors such as parts wear, air quality, line voltage fluctua-

tions, operator experience, standoff variation and quality

of ground may impact system performance.

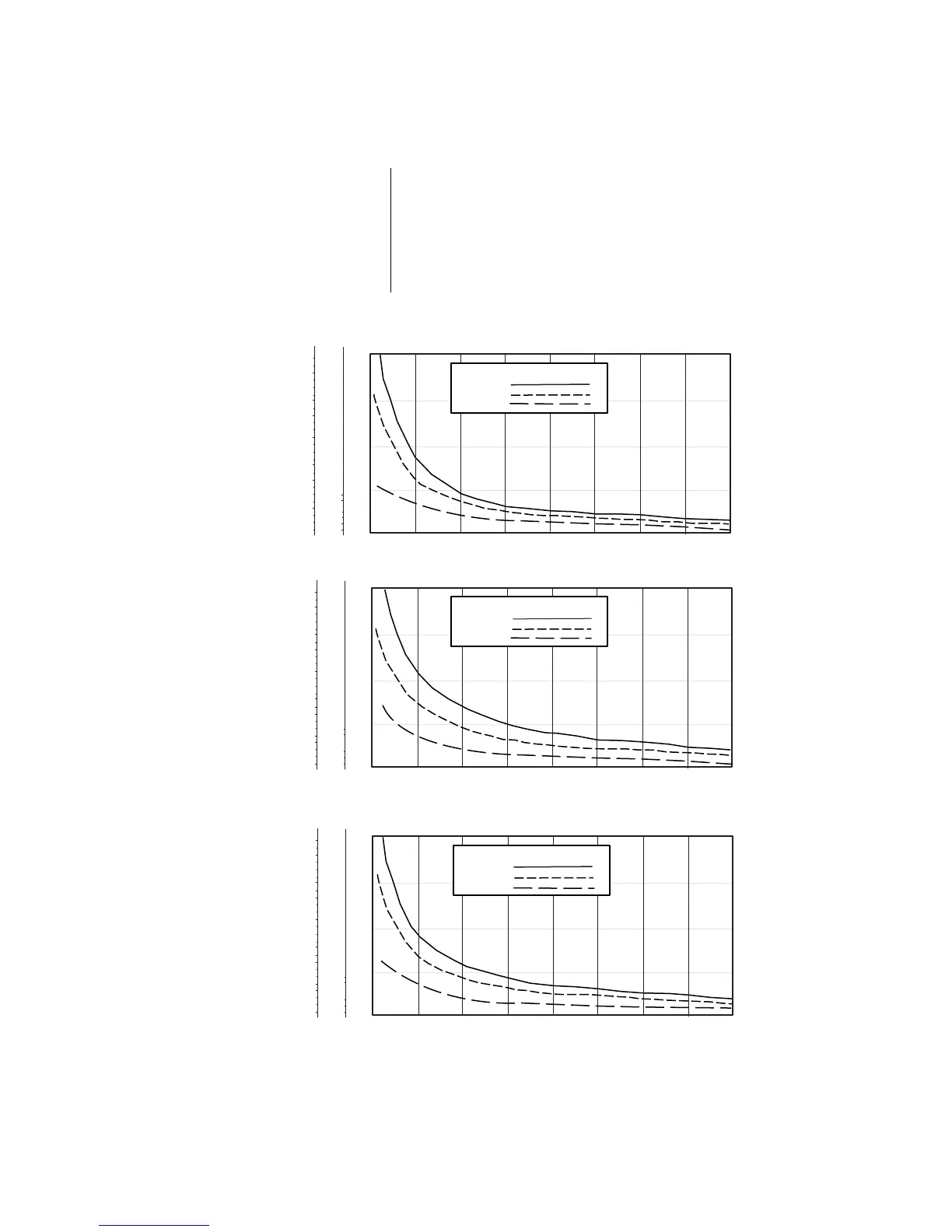

Figure 3-I PAK 1250 XR Cutting Speeds - Multi-Gas Operation

OPERATION

N2 / CO2 ON MILD STEEL

Range III

Range II

Range I

Inches per Minute 50 100 150 200 250 300 350 400

Meters per Minute 1.27 2.54 3.81 5.08 6.35 7.62 8.89 10.16

(mm) (gage) (in)

1.00

0.75

0.50

0.25

0.125

0.62

MATERIAL THICKNESS

25

20

15

10

5

4

8

12

16

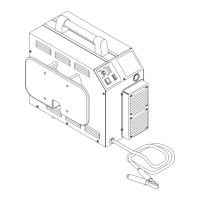

N2 / CO2 ON ALUMINUM

Range III

Range II

Range I

Inches per Minute 50 100 150 200 250 300 350 400

Meters per Minute 1.27 2.54 3.81 5.08 6.35 7.62 8.89 10.16

(mm) (gage) (in)

1.00

0.75

0.50

0.25

0.125

0.62

MATERIAL THICKNESS

25

20

15

10

5

4

8

12

16

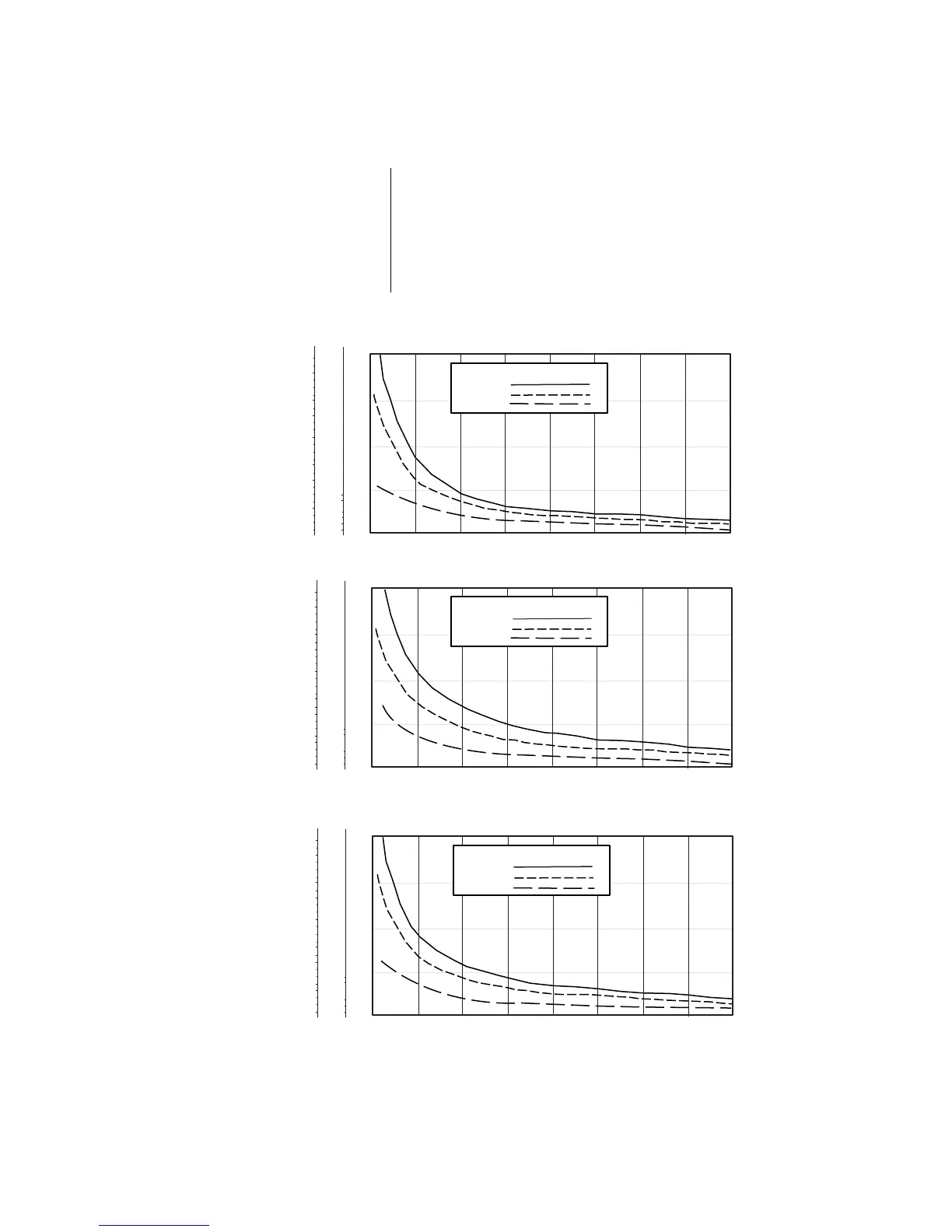

N2 / CO2 ON STAINLESS

Range III

Range II

Range I

Inches per Minute 50 100 150 200 250 300 350 400

Meters per Minute 1.27 2.54 3.81 5.08 6.35 7.62 8.89 10.16

(mm) (gage) (in)

1.00

0.75

0.50

0.25

0.125

0.62

MATERIAL THICKNESS

25

20

15

10

5

4

8

12

16

A-01479

CUTTING SPEED

CUTTING SPEED

CUTTING SPEED

Loading...

Loading...