19

3.3 CUTTING OPERATION (continued)

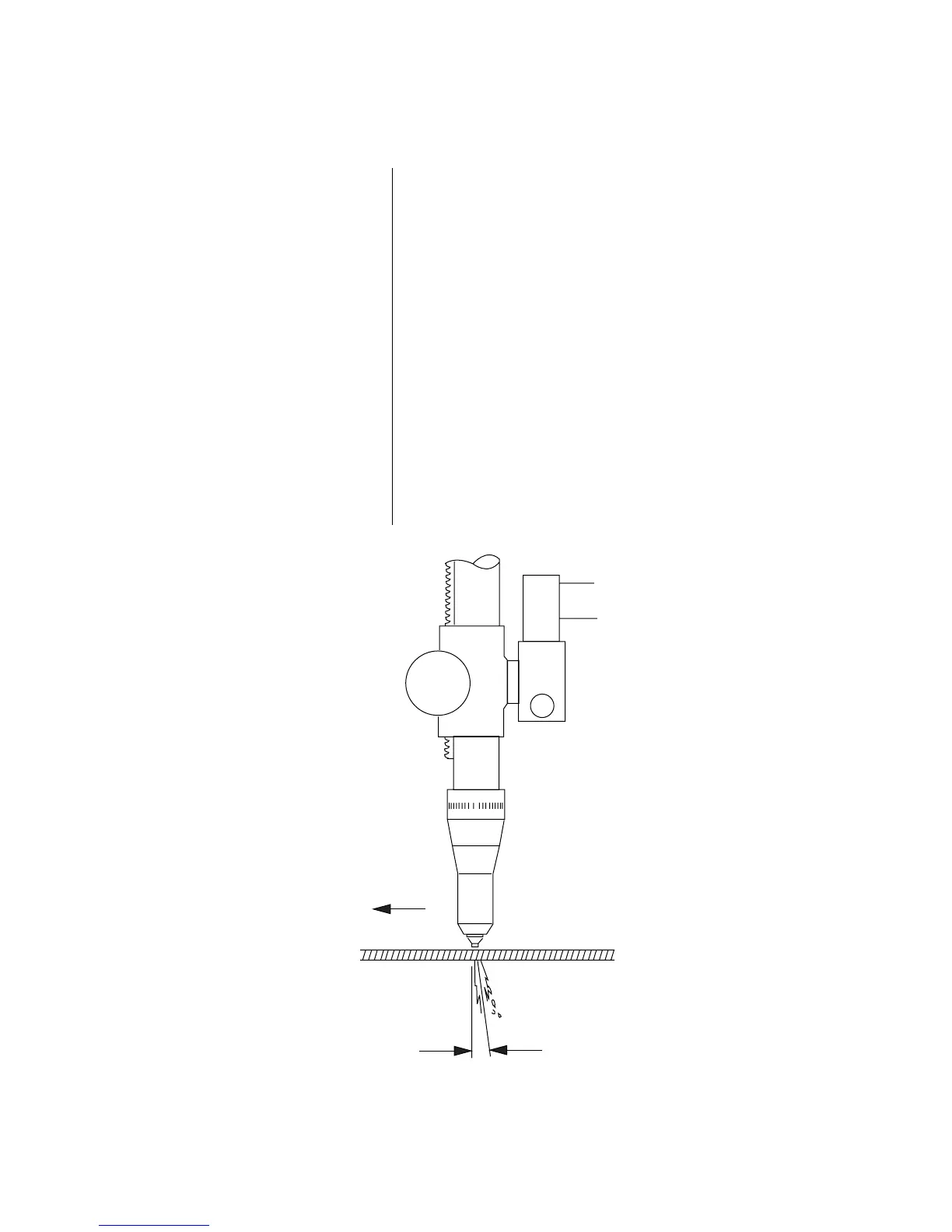

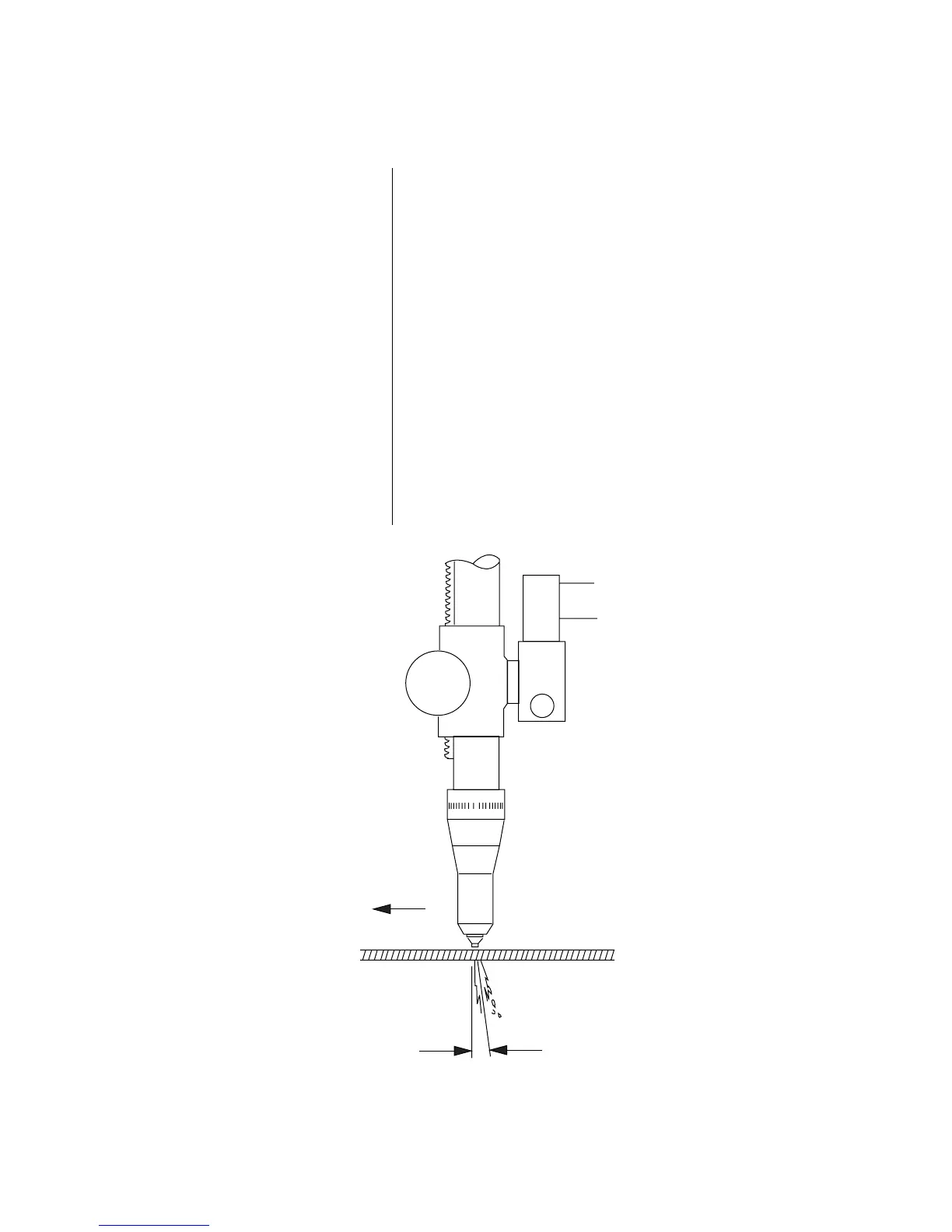

When using a machine torch, the torch should be aligned

perpendicular to the workpiece to obtain a clean, vertical

cut. Use a square to align the torch (see Figure 3-D).

The torch can be activated by remote control pendant or by

remote interface device. Start cutting slowly and increase

the speed to obtain the desired cut quality. Figures 3-H

and 3-I (page 24-25) contain typical cutting speeds for

various materials and material thicknesses.

To start a cut at the plate edge, line up the center of the

torch along the edge of the plate and press the control

switch. The transferred cutting arc will then be established

at the plate edge. Adjust cutting speed for optimum

cutting performance.

The arc characteristics vary with gases used, cutting speed,

material, and thickness. Air plasma normally produces a 5°

leading arc (on mild steel) or a straight arc (on stainless or

aluminum), while nitrogen plasma generally creates a 5°

trailing arc (see Figure 3-E).

Figure 3-E Machine Torch Operation

Cutting with a

Machine Torch

(continued)

OPERATION

Five Degree

Trailing Arc

Torch Travel

A-01475

Loading...

Loading...