22

3.4 GOUGING OPERATION (continued)

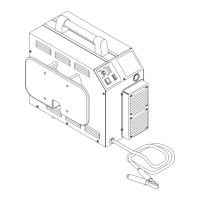

The angle at which the torch is held depends on the

current setting and the torch travel speed. At 35 amps,

(Range I), the recommended lead angle is 35°. At 105

amps (Range III), the recommended lead angle increases to

45°. An angle greater than 45° may result in inconsistent

metal removal. If the lead angle is too small (less than

35°), less material may be removed, requiring more passes.

In some applications, such as removing welds or working

with light metal, this may be desirable.

The tip to work distance affects gouge quality and depth.

A standoff of 1/8 - 1/4 in (3 - 6 mm) allows smooth,

consistent material removal. A smaller standoff may

result in a severance cut rather than a gouge. A standoff

greater than 1/4 in (6 mm) may result in minimal metal

removal or loss of transferred main arc.

Slag generated by gouging on materials such as carbon

and stainless steels, nickels, and alloyed steels, can be

removed easily in most cases. There is little, if any, slag

produced when gouging aluminum, as the material is

vaporized. Slag does not obstruct the gouging process if it

accumulates to the side of the gouge path. However, slag

build-up can cause inconsistencies and irregular metal

removal if large amounts of material build up in front of

the arc. The build-up is most often a result of improper

travel speed, lead angle, or standoff height.

Standoff Distance

Lead Angle

Slag Build-up

OPERATION

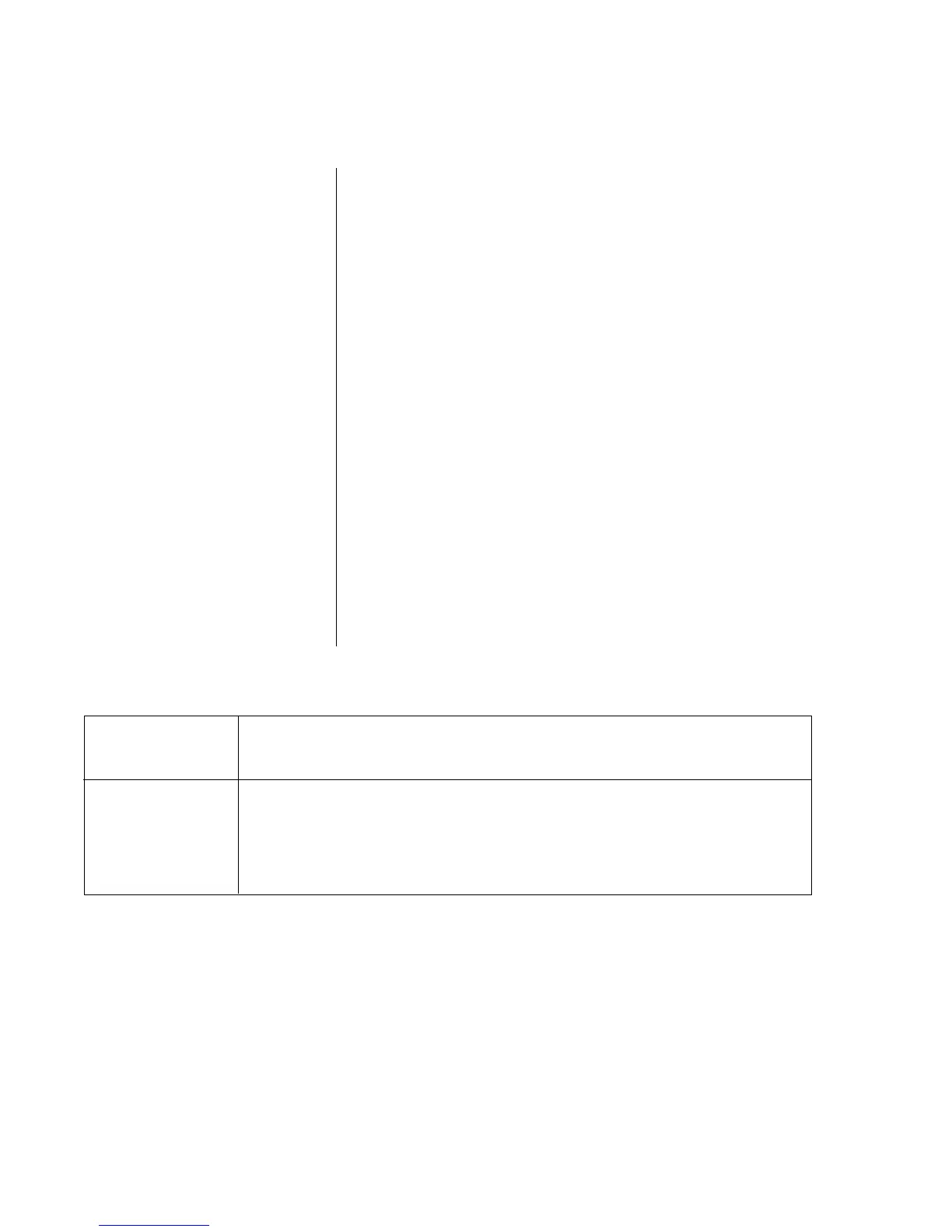

Plasma Gas Ar/H2 Ar/H2 Nitrogen Nitrogen Air

Secondary Gas Nitrogen Air Air CO2 Air

Carbon Steel Good Good Good Good Excellent

Stainless Steel Excellent Good Good Good Fair

Aluminum Excellent Good Fair Good Fair

Table 3-A Recommended Gases for Plasma Arc Gouging

Loading...

Loading...