TKS Operator's manual

42

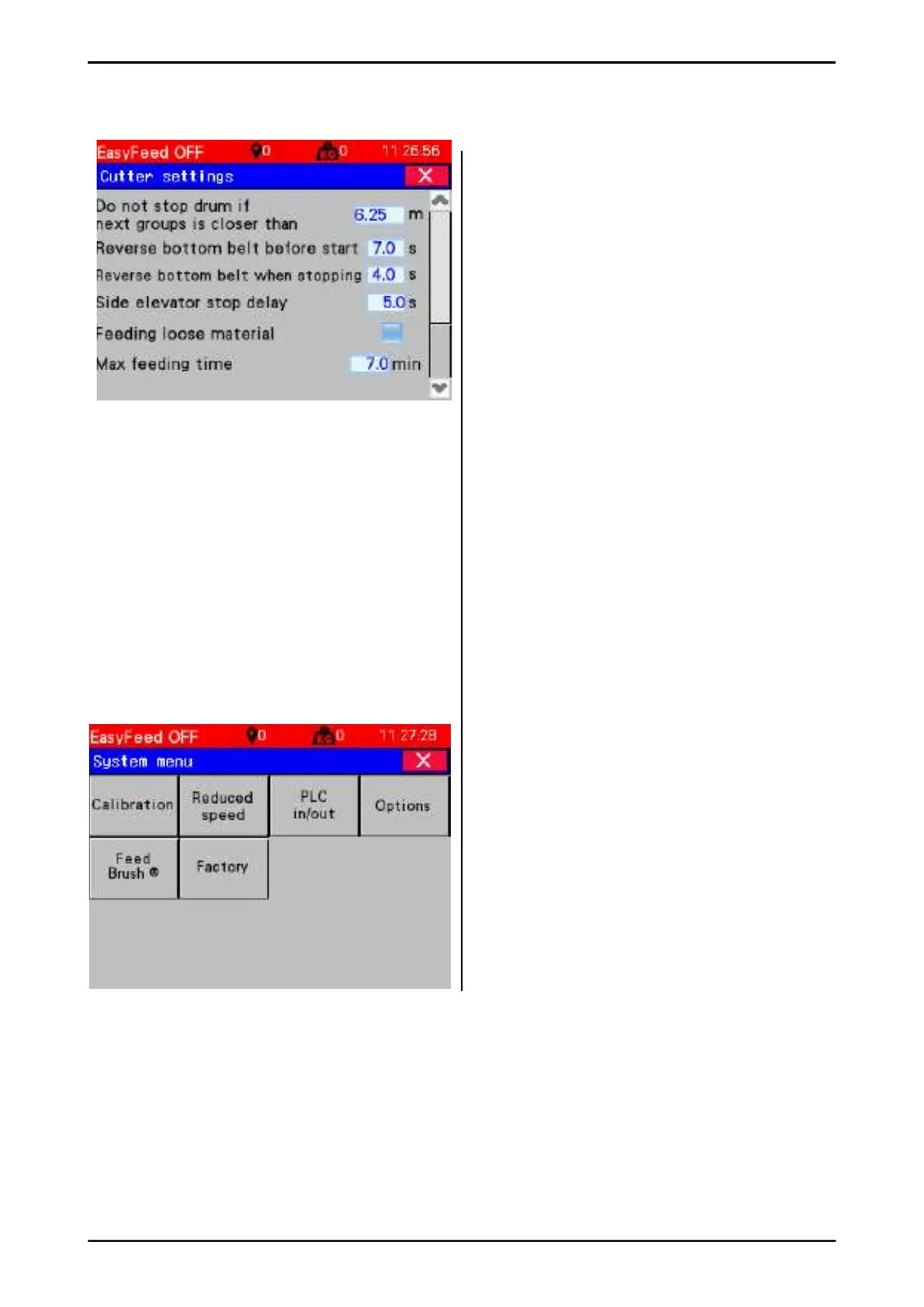

Fig. 65b

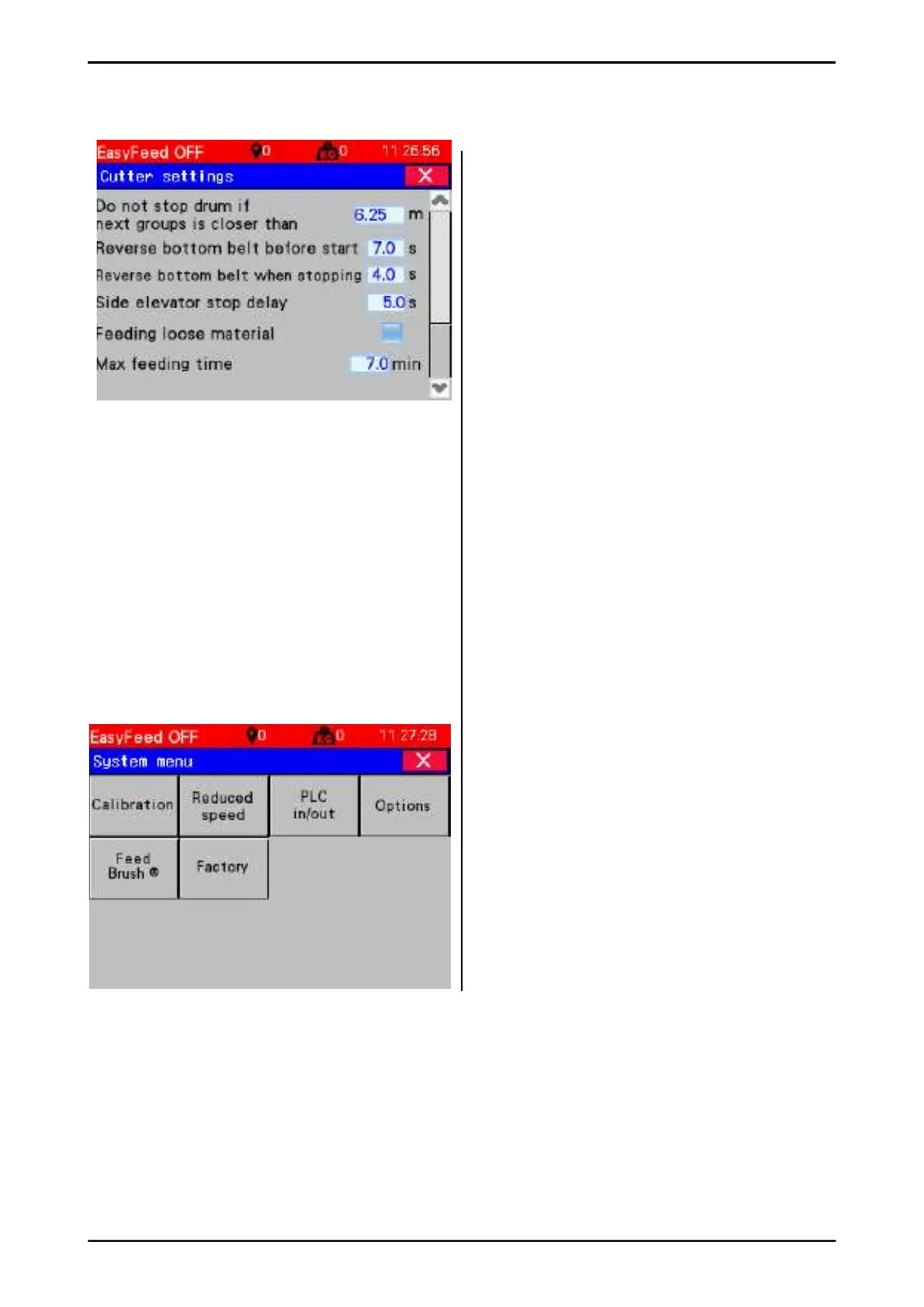

Fig. 66

Cutter settings Side 2

• Do not stop drum if next groups are

closer than – If multiple groups are fed in

succession, the drum and side dispenser

do not need to stop between each group.

The value indicates the permitted number of

metres to the next group where the drum is

to resume rotating.

• Reverse bottom belt before start – the

time the bottom belt needs to run in reverse

before the drum starts.

• Reverse bottom belt when stopping – the

time the bottom belt needs to run in reverse

after feeding has fi nished.

• Side elevator stop delay – when feeding

stops, the feeder continues for as long as

this time indicates.

• Feeding loose material – bottom belt runs

in fi xed speed step, and does not follow

pressure on drum.

• Max feeding time – Maximum time it is

allowed to run on a feeding.

3.5.5 System menu

Open the menu for programming the feed

dispensing machine. Press the Menu key at the

bottom left of the Menu bar.

• Calibration – Defi ne the drive path along the

rail.

• Reduced speed – Location of reduced

speed zones at bends.

• PLC in / out – Displays PLC inputs and

outputs.

• Options – Selection of installed additional

equipment.

• Feed Brush – Feed Brush settings.

• Factory – Resetting the factory settings.

Loading...

Loading...