TKS Operator's manual

55

4 Alarms and troubleshooting

If a protection device has cut out due to overload, motors MUST be allowed to cool suffi ciently

before restarting (wait a minimum of 20 minutes).

4.1 Alarms on controlbox

In the event of a fault, the alarm window is displayed on the screen

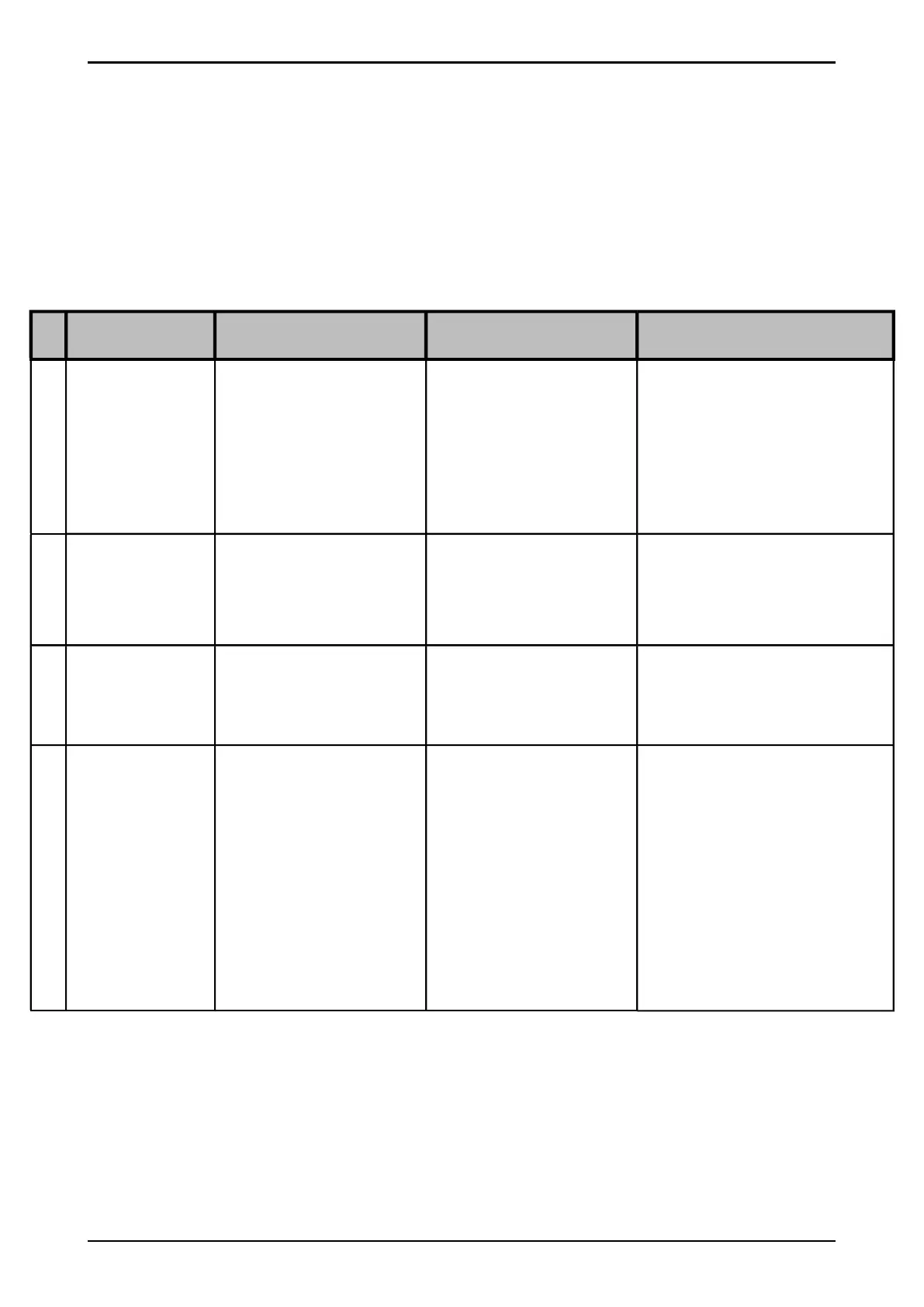

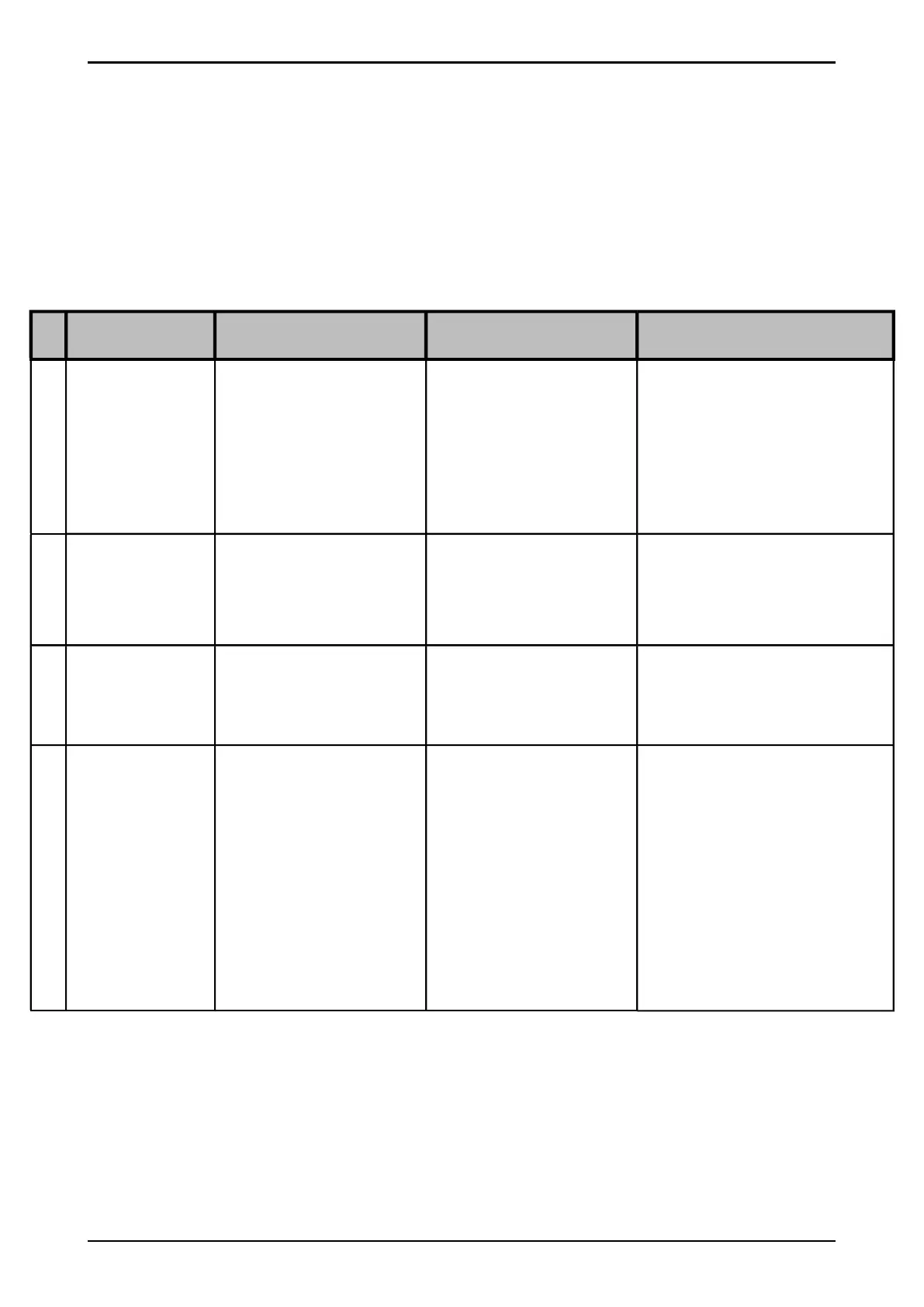

No Alarm text Fault - explanation Possible error causes Procedure - error correction

1 Emergency stop The emergency stop is

triggered

• An emergency has

been pressed in

• Stop” button on

thescreen in the

controlbox is pressed

• Efter an emergency

stop, the machine’s working

area must be checked.

To release all emergency

stop switches, twist in the

direction of the arrow

• Reset the alarm

2 Sync.

Sensor 1 fault

Sync. switch 1 is

incorrect

• Sync.switch is not

connected

• Syncronisation is

broken

• Connect the sync. switch

• Change the sync. switch

3 Sync. sensor 1

(2) fault

Error on sync. switch 1

(2)

• Sync. switch1 (2) is not

connected or is

defective

• Connect to the sync. switch

• Shift the sync. switch.

4 Ceiling rail unit

error

The control sends

a command to move

the machine, but no

movement is recorded

• Position counter

sensor error or the

cables are defective

• Fault in ceiling rail unit

motors

• The machine has

collided with a foreign

object

• Check position of the

position counter

sensors and whether the

cables are in order

• Check whether the wheel

rolls freely on the rail

• Check ceiling rail unit

motors

• Check if there are foreign

objects in the path of the

machine

Loading...

Loading...