Regular Payload Series-Hardware Installation Manual TM5 Series Hardware Version:3.1 Document Version:1.01 74

7. Maintenance and Repair

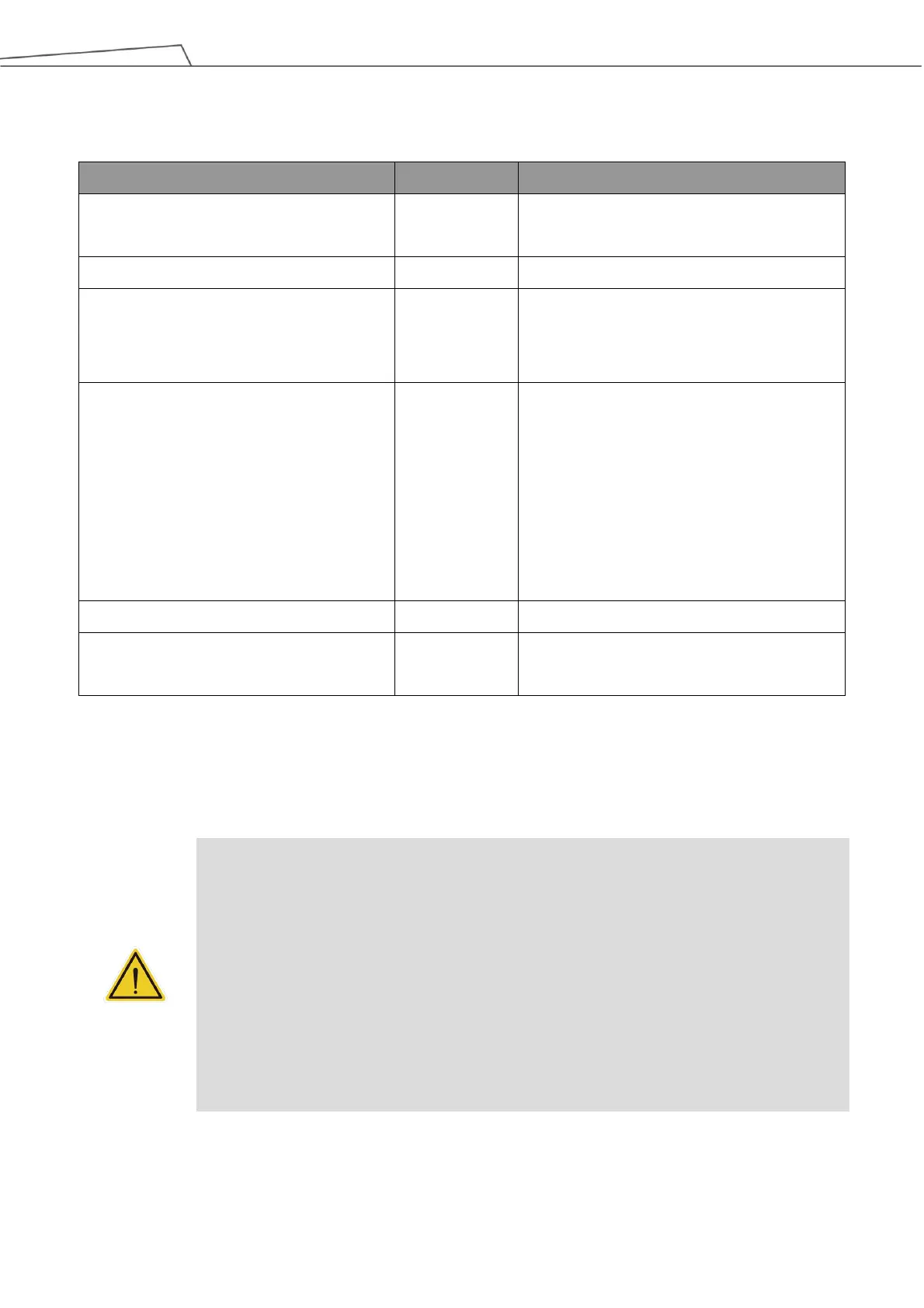

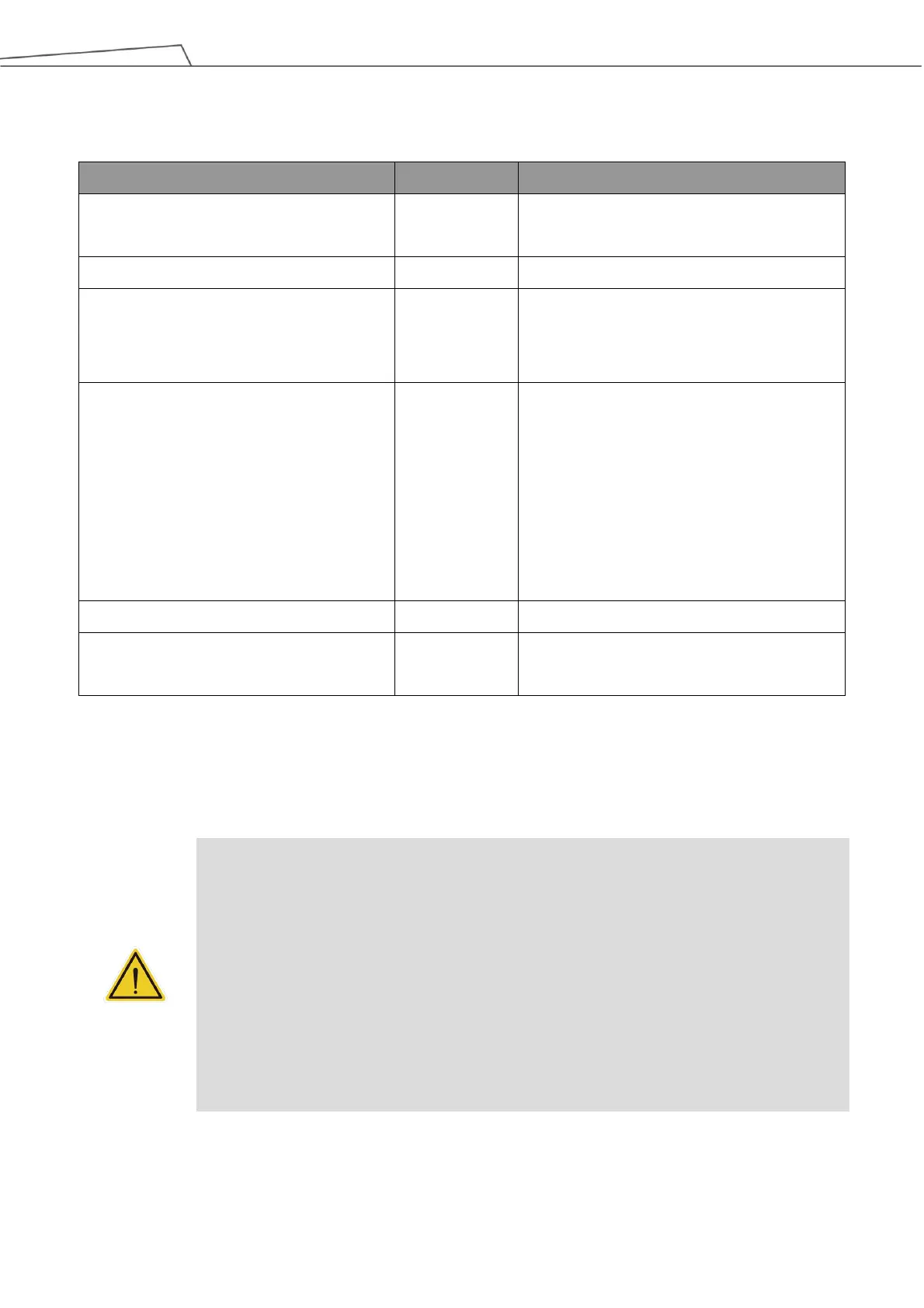

The following table gives a summary of the preventive maintenance procedures and guidelines:

Ensure labels are present and legible.

Replace them if necessary.

Replace filter every 3 months.

Press the Emergency Switch and the IO

E-Stop in open-loop status. Verify that each

shuts off power.

Check Safeguard Ports (A, B)

When the Safeguard A Port is in the

open-loop state, the indication light of current

mode will be constantly flashing.

When the Safeguard B Port is in the

open-loop state, the purple light will be

alternating between the indication light of the

current mode.

Check Robot Mounting Screws

Follow ”4.2.1.6 Robot Arm Installation”

EMO button (SEMI version only)

Press the EMO button. Verify that power

shuts off.

Table 18: Summary of the Preventive Maintenance Procedures and Guidelines

Only the legal distributor or authorized service center should repair the TM Robot. Users should not repair it by

themselves.

DANGER:

Before performing maintenance or service record the details of each setting for the robot for

normal operation. Make sure that each setting satisfies the original conditions before resuming

normal operation, including but not limited to:

Safety Software Settings

Safety I/O

Preset operation project

TCP Settings

I/O Settings

I/O Wiring

Loading...

Loading...