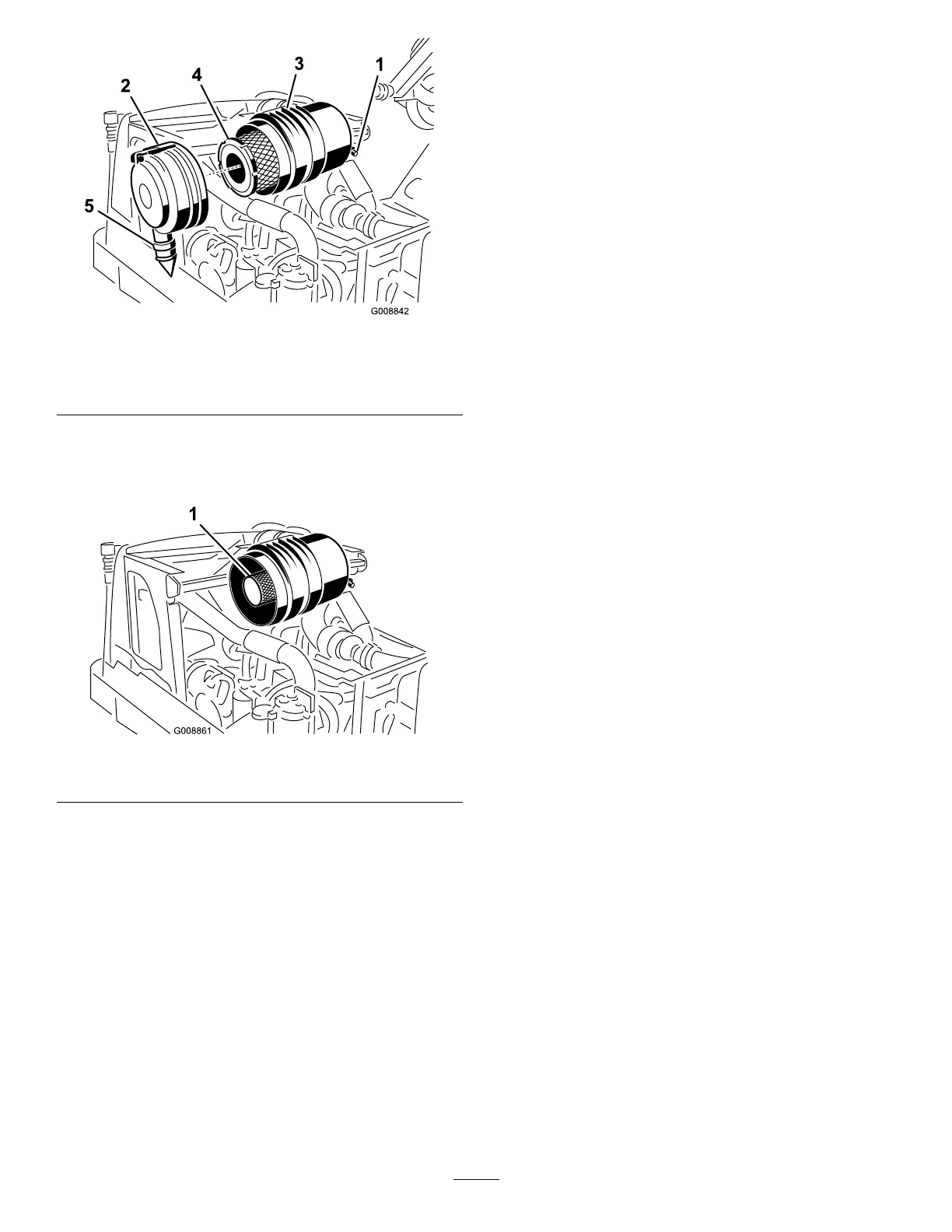

Figure57

1.Aircleanerindicator

4.Aircleanerprimarylter

2.Aircleanerlatch5.Rubberoutletvalve

3.Aircleanerbody

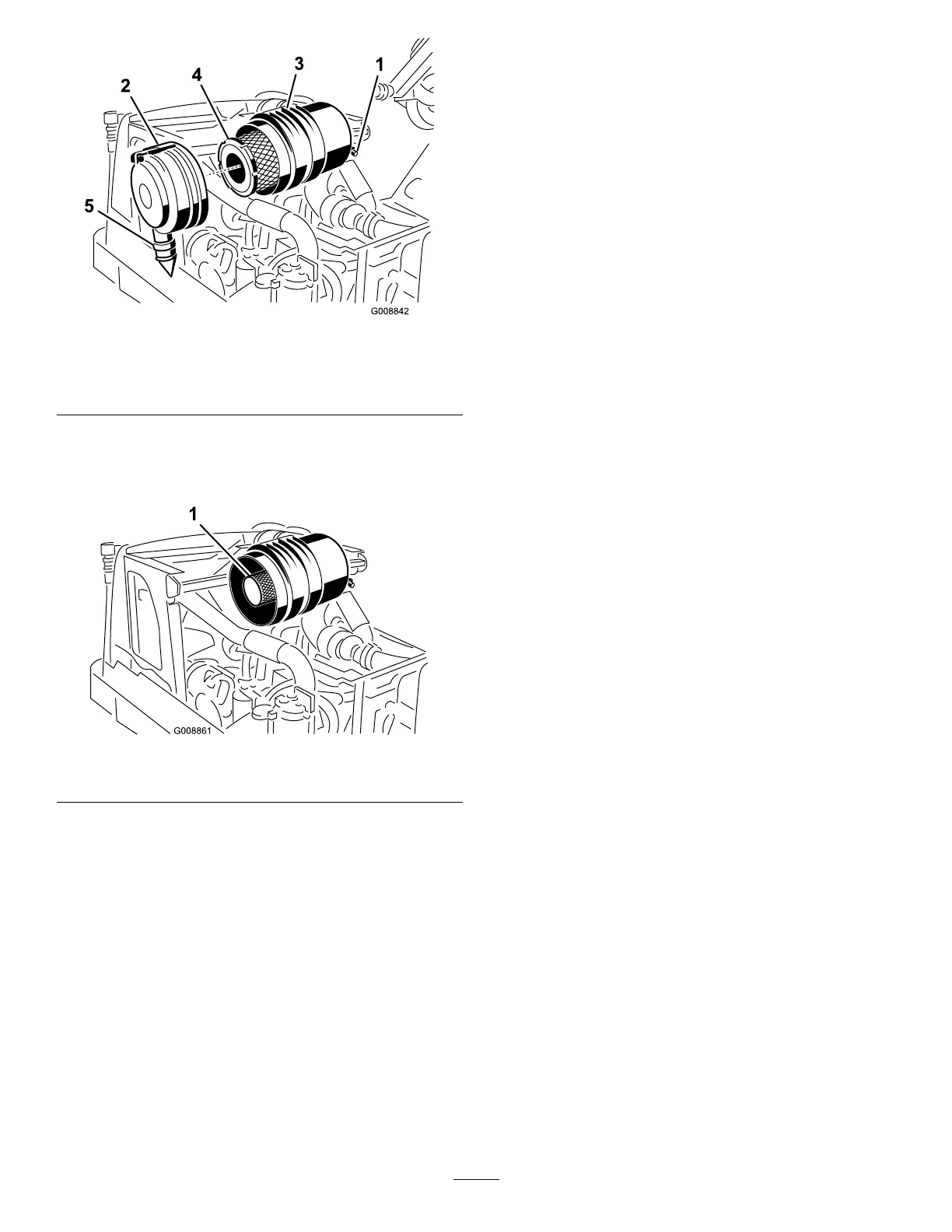

Important:Neverattempttocleanthesafety

lter(Figure58).Replacethesafetylterwitha

newoneaftereverythreeprimarylterservices.

Figure58

1.Safetylter

3.Replacetheprimarylter(Figure57).

4.Insertthenewlterbyapplyingpressuretotheouter

rimoftheelementtoseatitinthecanister.Donot

applypressuretotheexiblecenterofthelter.

5.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthe

cover,cleanthecavityandreplacetheoutletvalve.

6.Installthecoverorientingtherubberoutletvalve

(

Figure57)inadownwardposition-between

approximately5:00to7:00whenviewedfromthe

end.Securethelatch.

ServicingtheEngineOil

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily—Checkthe

engineoillevel.

Theengineisshippedwithoilinthecrankcase;however,

theoillevelmustbecheckedbeforeandaftertheengine

isrststarted.

Thecrankcasecapacityis8.5qt(8.04l)withthelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher.

•Preferredoil:SAE15W-40(above0°F)

•Alternateoil:SAE10W-30(below23°F)

ToroPremiumEngineOilisavailablefromyour

distributorineither15W-40or10W-30viscosity.See

thepartscatalogforpartnumbers.Also,refertothe

EngineOperator’sManual,includedwiththemachine,for

furtherrecommendations.

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifit

hasalreadybeenrun,allowtheoiltodrainbackdown

tothesumpforatleast10minutesbeforechecking.If

theoillevelisatorbelowthe‘add’markonthedipstick,

addoiltobringtheoilleveltothe‘full’mark.Donot

overll.Iftheoillevelisbetweenthe‘full’and‘add’

marks,nooiladditionisrequired.

1.Parkthemachineonalevelsurface.

2.Removethedipstick(

Figure59).,wipeitclean,install

thedipstickintothetube,andpullitoutagain.The

oillevelshouldbeuptotheFullmark.

46

Loading...

Loading...